Device applied to automatic welding of T-shaped welding stud with ceramic ring

A ceramic ring and welding stud technology is applied in the field of automatic T-shaped welding stud welding devices, which can solve the problems affecting the health of welding workers, the welding quality cannot be guaranteed, and the bone hyperplasia of welding workers, etc., and achieves a high degree of freedom of operation and automation High-level, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

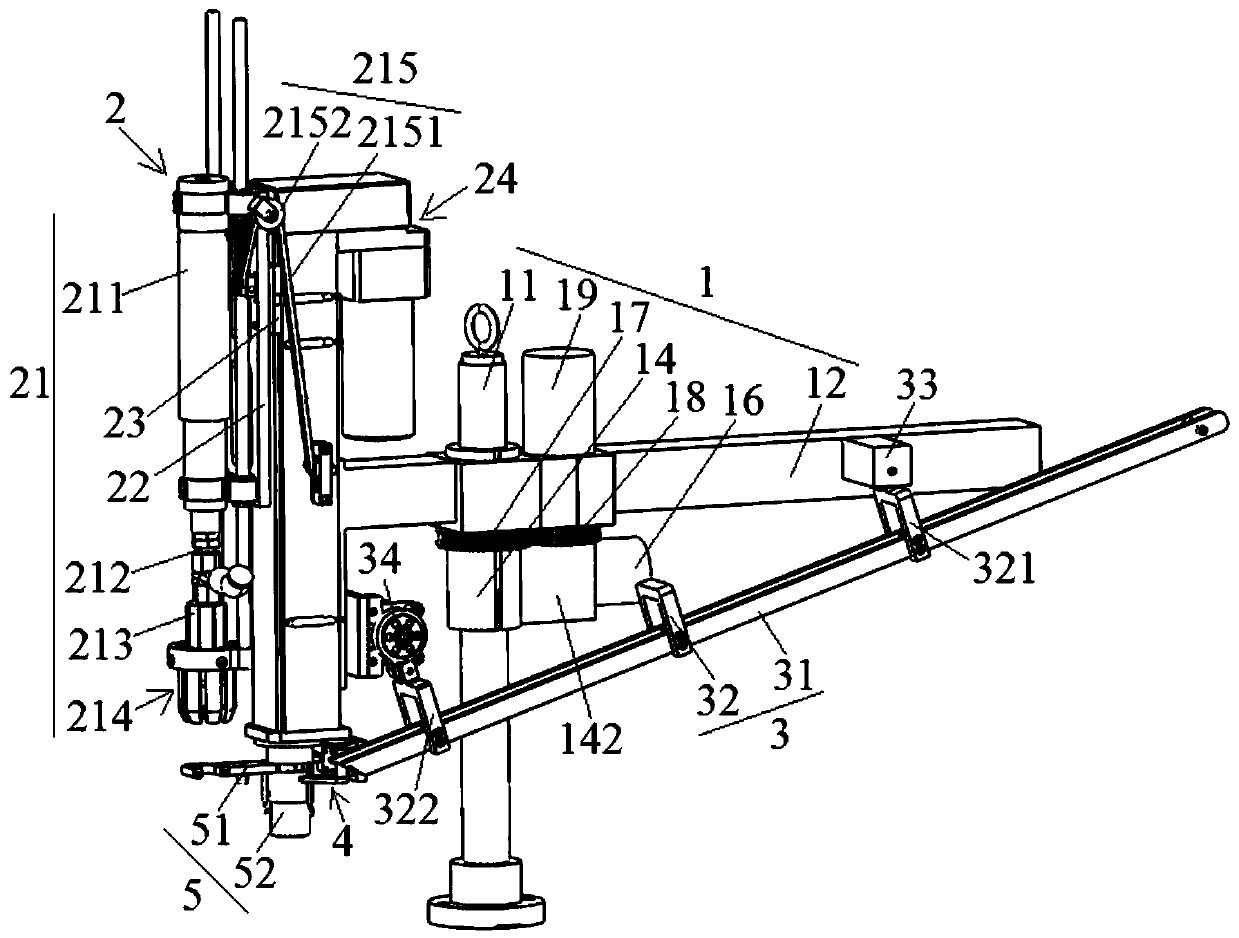

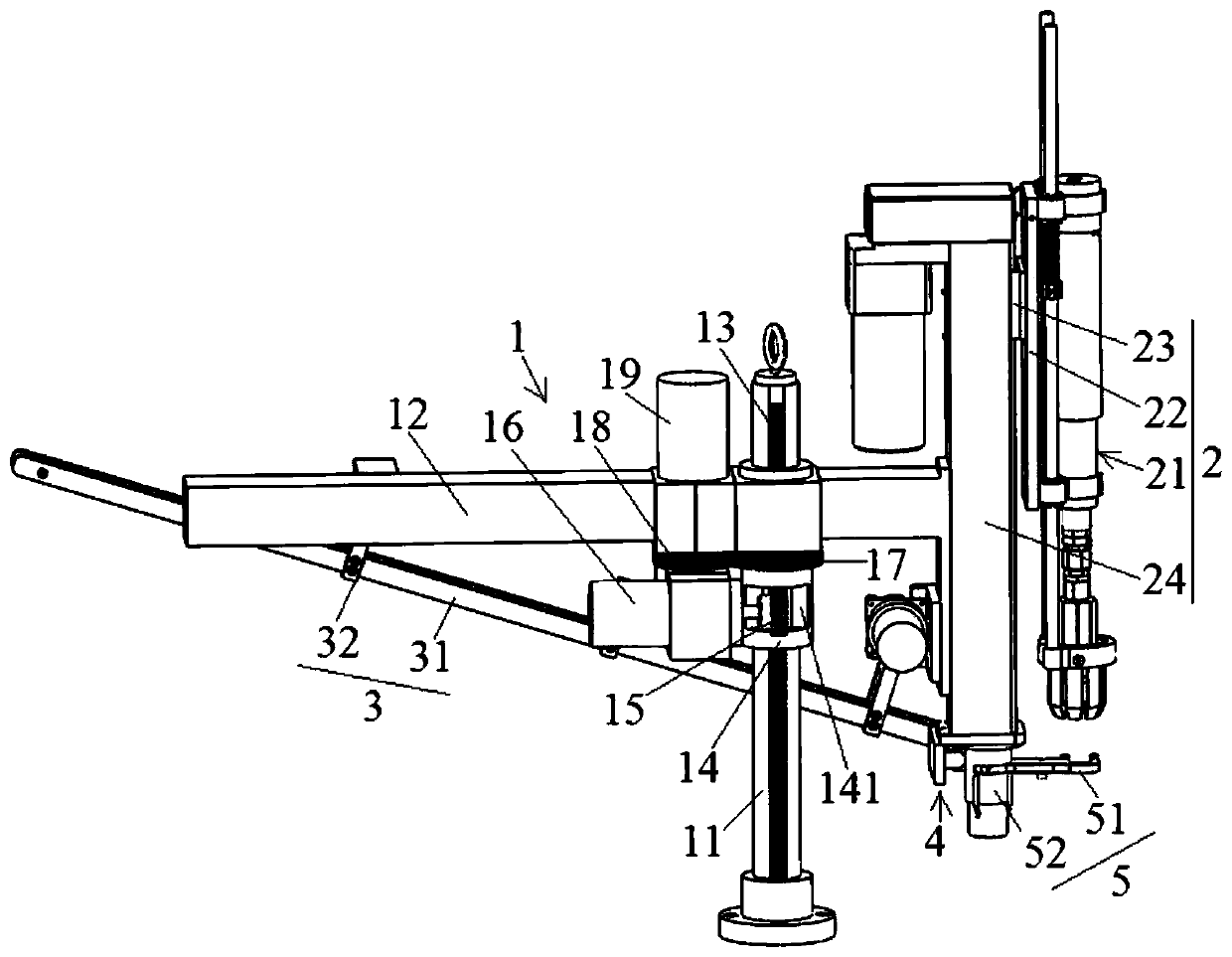

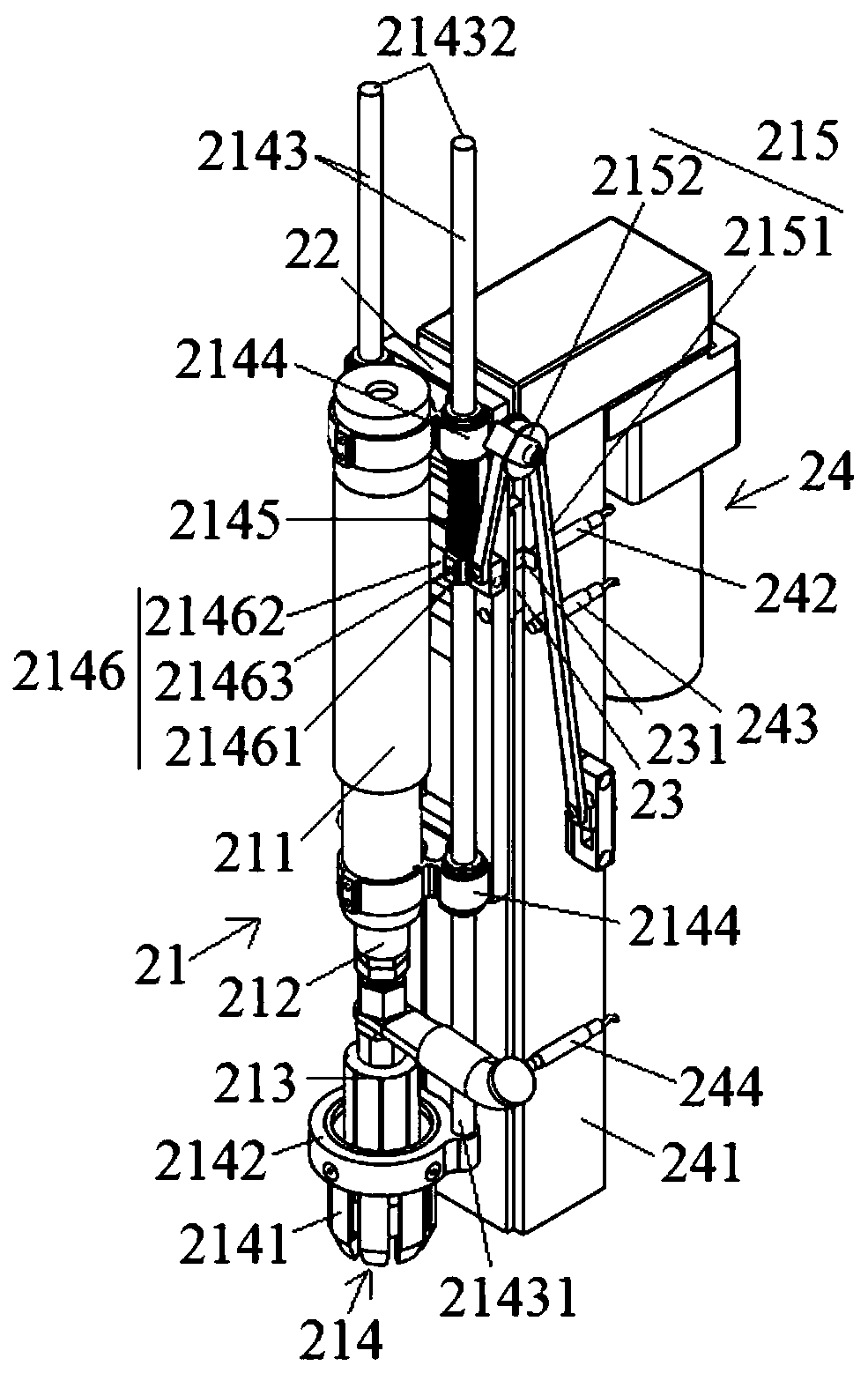

[0063] Please combine figure 1 and figure 2 Shown: This embodiment provides a device for automatic welding of T-shaped welding studs with ceramic rings, including a mounting frame 1, an automatic welding gun 2, a material clamp 3, a feeding assembly 4 and a feeding assembly 5.

[0064] The mounting frame 1 includes a column 11 and a transverse support 12, the transverse support 12 is sleeved on the column 11, and can move up and down on the column 11 and rotate 360 degrees around the column 11 (the specific implementation of the present embodiment It is: a straight line rack 13 is provided in the longitudinal direction of the column 11, and a sliding sleeve 14 that can slide up and down but does not rotate around it is sleeved on the column 11, and the horizontal bracket 12 is rotatably sleeved on the column. On the sliding sleeve 14, the lower part of the sliding sleeve 14 is provided with an opening 141 for the meshing connection between the lifting gear 15 and the linea...

Embodiment 2

[0081] See Figure 11 As shown, the present embodiment provides a device for automatic welding of T-shaped welding studs with ceramic rings. The only difference from the device described in Embodiment 1 is that the device also includes a horizontally moving base 6 and an electrical controller 7 , the rest of the content is the same as described in Example 1.

[0082] Please combine Figure 11 and Figure 12 Shown: described horizontal movement base 6 is made up of horizontal base plate 61 and some universal ball wheels 62 arranged on the bottom of horizontal base plate 61 and 4 groups of wire rope traction mechanisms 63 arranged on horizontal base plate 61, each group of wire rope traction mechanisms 63 Both include a steel wire rope 631, an electric wire rope winch 632 and an alignment sensor 633. The front end of the steel wire rope 631 is provided with a fixed hook 6311. By making the fixed hook 6311 fixed, the electric wire rope winch 632 is then used to rewind the wire ...

Embodiment 3

[0087] See Figure 15 and Figure 16 As shown, the device provided in this embodiment to realize the automatic welding of T-shaped welding studs with ceramic rings is only different from the device described in Embodiment 2 in that the horizontally movable base 6 is composed of a bow-shaped bottom plate 64 and a set Several universal ball wheels 62 at the bottom of the two wings of the arcuate base plate 64 and steel wire rope traction mechanisms 63 symmetrically arranged on the two wings of the arcuate base plate 64 are formed. The front end of the steel wire rope 631 is provided with a fixed hook 6311. By fixing the fixed hook 6311, the electric wire rope winch 632 is used to rewind the wire rope 631 or unwind the wire rope 631 to drive the arcuate base plate 64 to move forward or backward; The bottom end is fixed on the arcuate base plate 64, thereby can realize the walking movement of the whole device of the present invention.

[0088] Depend on Figure 17 and Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com