Shore bridge tilting-snagging integrated electric hydraulic control system and method

An electro-hydraulic control system and electro-hydraulic control technology, which are used in the testing of fluid pressure actuation systems, load suspension components, fluid pressure actuation devices, etc., can solve high energy consumption, complex hydraulic pipelines, and complex fault handling problems, to achieve the effect of reducing the number of spare parts, reducing the amount of construction, and reducing repeated designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

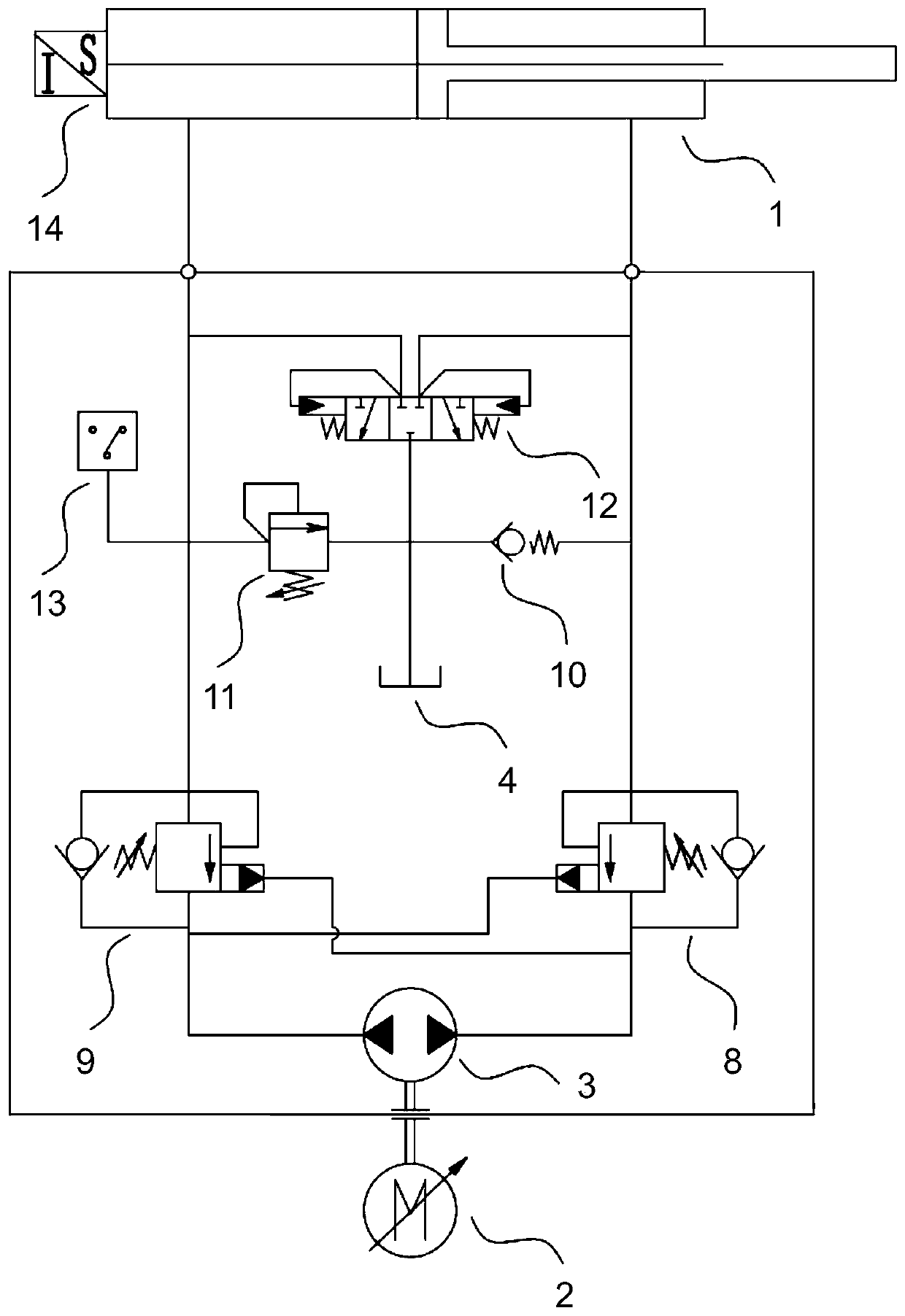

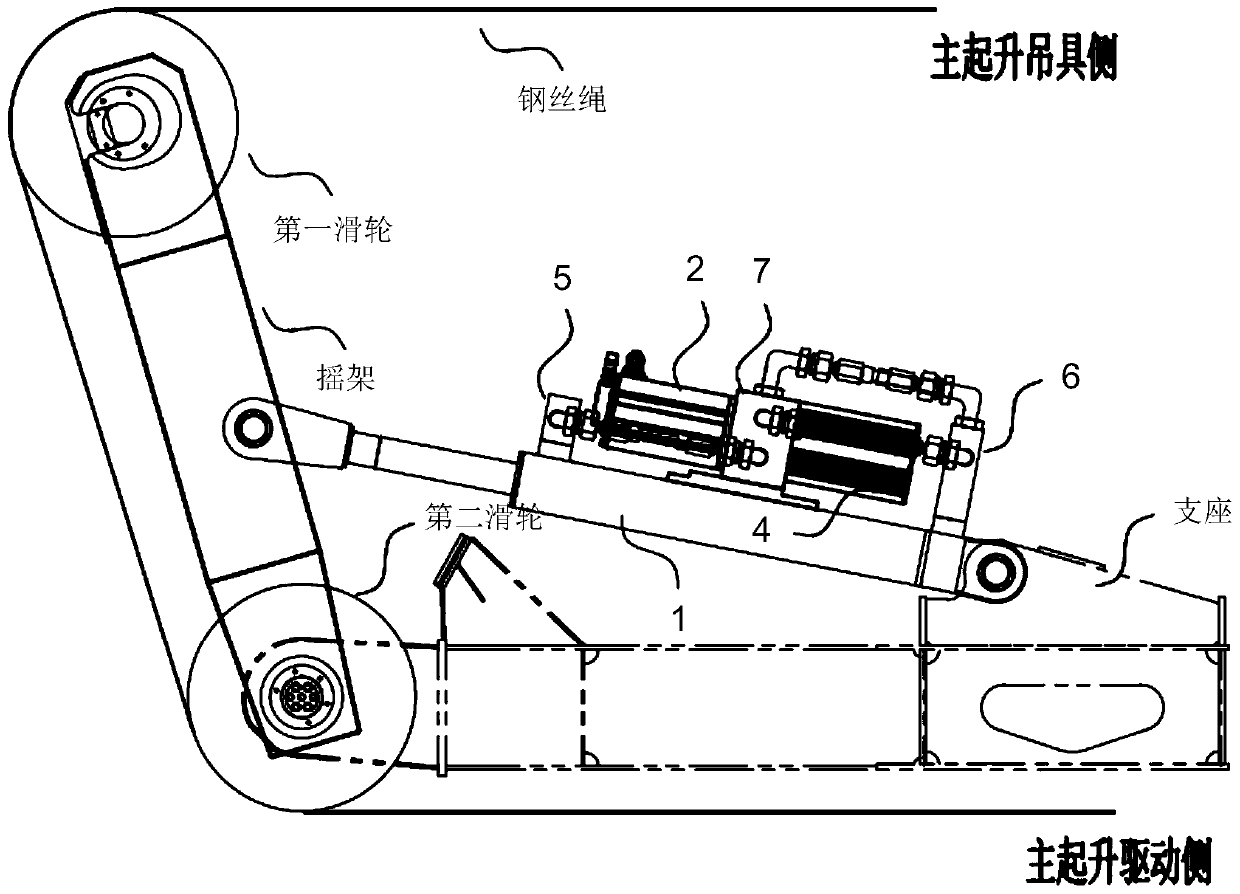

[0026] Please combine Figure 1 to Figure 2 As shown, an integrated electro-hydraulic control system for quay crane tilting and storage tank provided by the present invention includes a servo driver, an electro-hydraulic drive module and a hydraulic cylinder 1 connected in sequence.

[0027] Preferably, the electro-hydraulic drive module includes a servo motor 2, a hydraulic pump 3, a valve block 7 and an integrated oil tank 4, the servo motor 2 is electrically connected to the servo driver, and one end surface of the valve block 7 is connected to the servo motor The other end of the valve block 7 is connected and sealed with the mounting flange of the integrated oil tank 4. The hydraulic pump 3 is placed in the integrated oil tank 4. The input shaft of the hydraulic pump 3 is connected to the servo motor 2 through a coupling....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com