Methanol gasoline additive, preparation method thereof and methanol gasoline containing additive

A technology of methanol gasoline and additives, applied in the field of gasoline additives, which can solve the problems of difficult separation, high cost, and lack of good separation methods, and achieve the effect of increasing combustion value and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

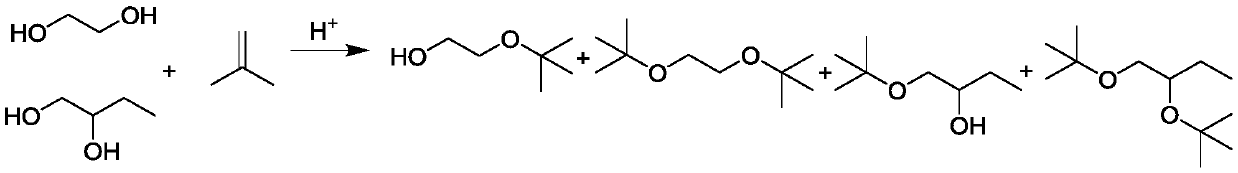

Method used

Image

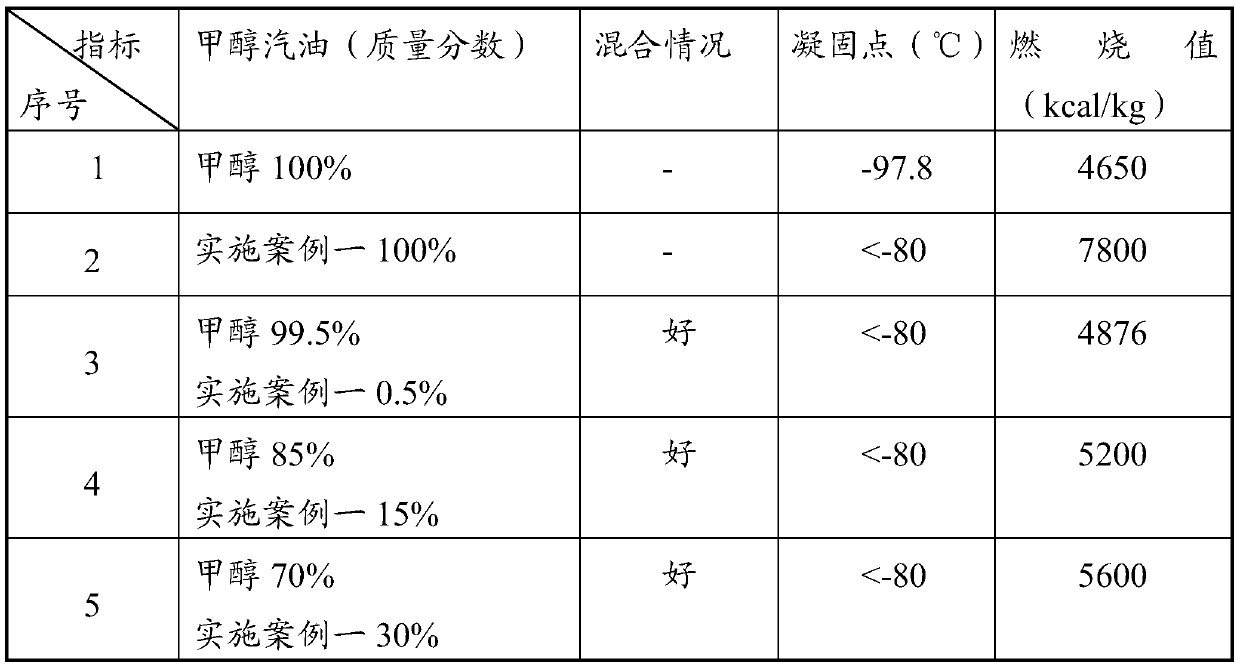

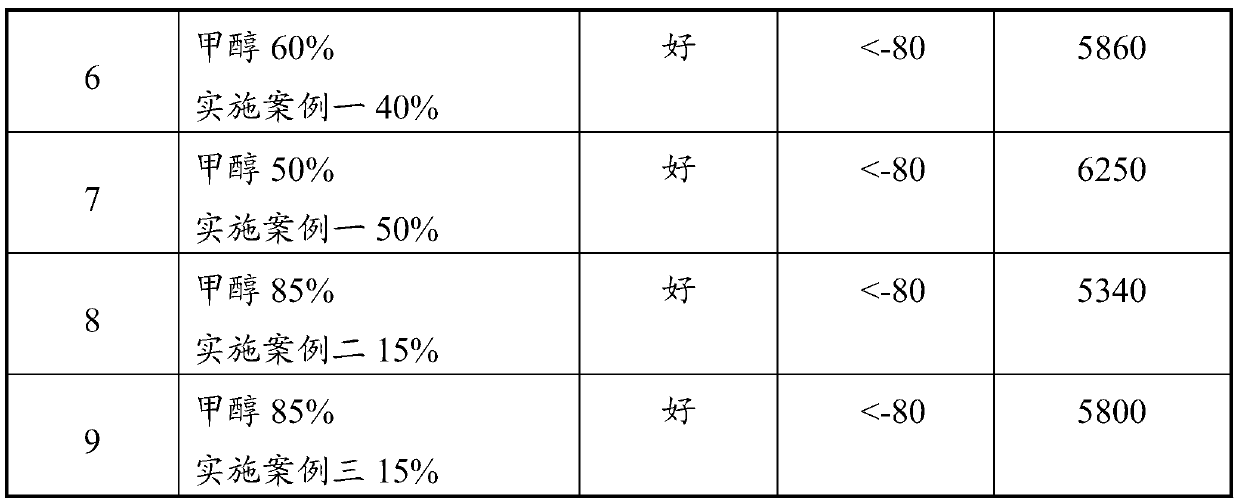

Examples

Embodiment example 1

[0052] Add 1000 grams of mixed glycol (ethylene glycol: 1,2-butanediol = 5:1) to a 2000 mL three-necked flask, add A15 resin acid catalyst 5% (by weight of mixed glycol), and the reaction system The temperature was raised to 85° C., and 2 equivalents of isobutene (equivalent to twice the amount of the diol substance) were introduced. Nitrogen was introduced to make the system pressure reach 2MPa. Under these reaction conditions, the reaction was carried out for 8 hours, and after cooling to room temperature, unreacted isobutene was recovered. The glycol ether in the product is recovered by distillation under reduced pressure, and the calculated yield is more than 95% (calculated on the basis of mixed glycol).

Embodiment example 2

[0054] Coal-based ethylene glycol waste (ethylene glycol: 1,2-butanediol = 5.5: 1) 1000 grams, methyl tert-butyl ether 1782 grams, added to a 3000 mL three-necked flask, heated to 70 ° C, added 100 g SO 4 2- / SiO 2 . The reaction was continued at 70°C for 15 hours. After cooling to room temperature, unreacted isobutene was recovered. The catalyst is removed by filtration, methanol and unreacted methyl tert-butyl ether are evaporated under normal pressure, and then the glycol ether in the product is recovered by distillation under reduced pressure, and the yield is more than 85% (calculated as mixed glycol).

Embodiment example 3

[0056] Coal-based ethylene glycol waste (ethylene glycol: 1,2-butanediol = 6: 1) 1000 grams, methyl tert-butyl ether 2376 grams, added to a 3000 mL three-necked flask, heated to 70 ° C, added 50 g SO 3 H-SBA-15. The reaction was continued at 70°C for 15 hours. After cooling to room temperature, unreacted isobutene was recovered. The catalyst is removed by filtration, methanol and unreacted methyl tert-butyl ether are evaporated under normal pressure, and then the glycol ether in the product is recovered by distillation under reduced pressure, and the yield is more than 92% (calculated as mixed glycol).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com