Novel floor heating laying structure, temperature control system and temperature control method

A new type of floor heating technology, applied in hot water central heating systems, heating systems, heating methods, etc., can solve problems such as inability to deliver hot water, out-of-control heating temperature, physical discomfort, etc., to weaken the unstable state of hot water, The effect of uniform hot water quantity, temperature and flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

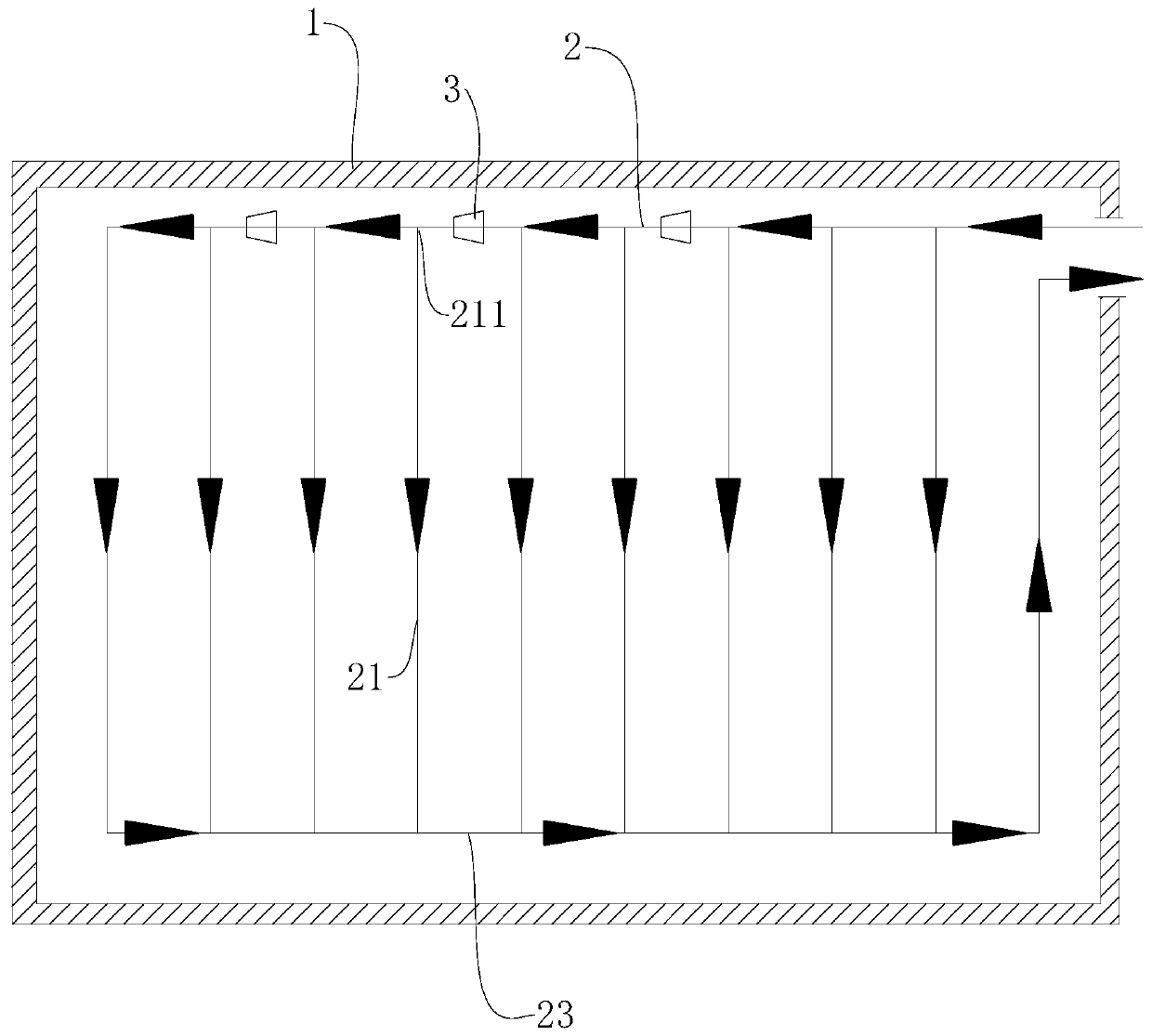

[0066] This embodiment provides a new floor heating laying structure, temperature control system and temperature control method, the structure of which is shown in the figure.

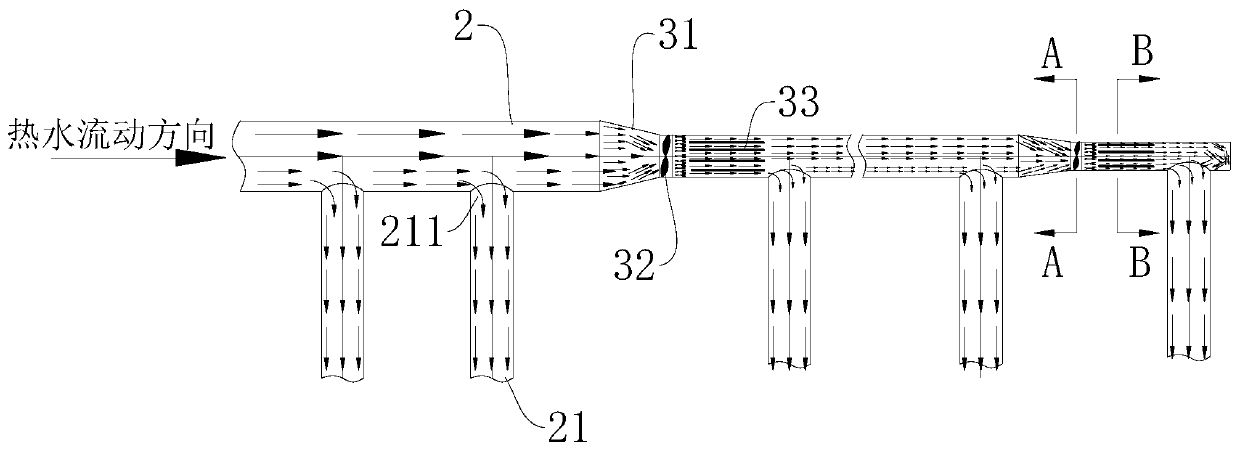

[0067] The new floor heating laying structure, temperature control system and temperature control method include: radiant pipes, connected to the user's main pipe 51, entering the heating area and detouring along the heating boundary 1 for a circle, including water inlet distribution pipes for hot water inflow 2 and the return water collecting pipe 23 where the hot water flows out; at least one branch pipe 21, including the water inlet 211 and the water outlet, the water inlet 211 is connected to the water inlet distribution pipe 2, and the water outlet is connected to the return water collecting pipe 23.

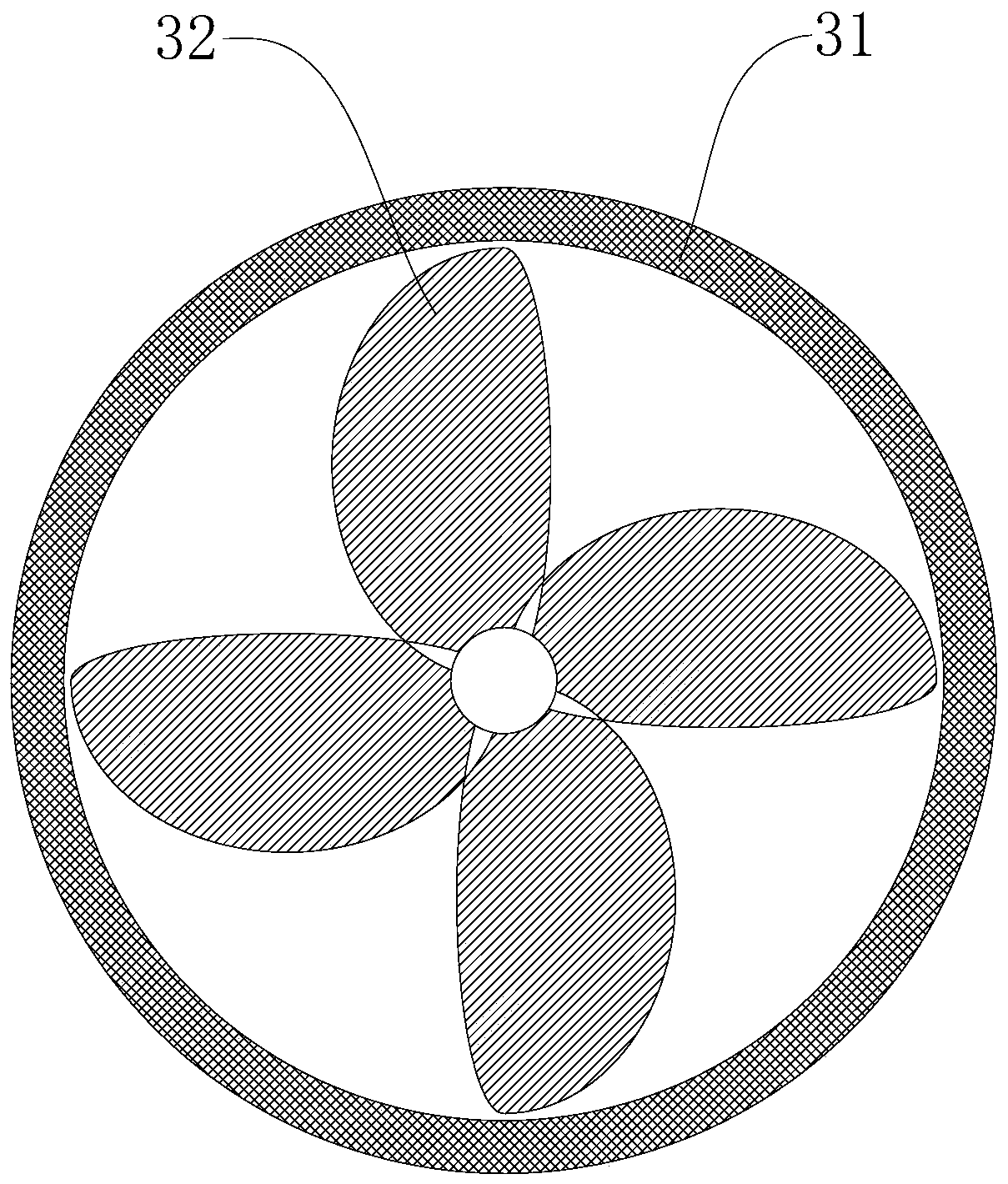

[0068] It also includes: at least one constant velocity assembly 3, which is arranged on the water inlet distribution pipe 2, one end for hot water to flow in, and one end for hot water to flow out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com