Energy accumulating type efficient air-cooled heat pump unit

An air-cooled heat pump and energy storage technology, which is applied in the field of air-conditioning heat pumps, can solve the problems of high compression ratio of compressors, high exhaust temperature, system cooling capacity/heating capacity and energy efficiency ratio decline, so as to improve reliability and reduce Ingenious effect of operating cost and unit design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

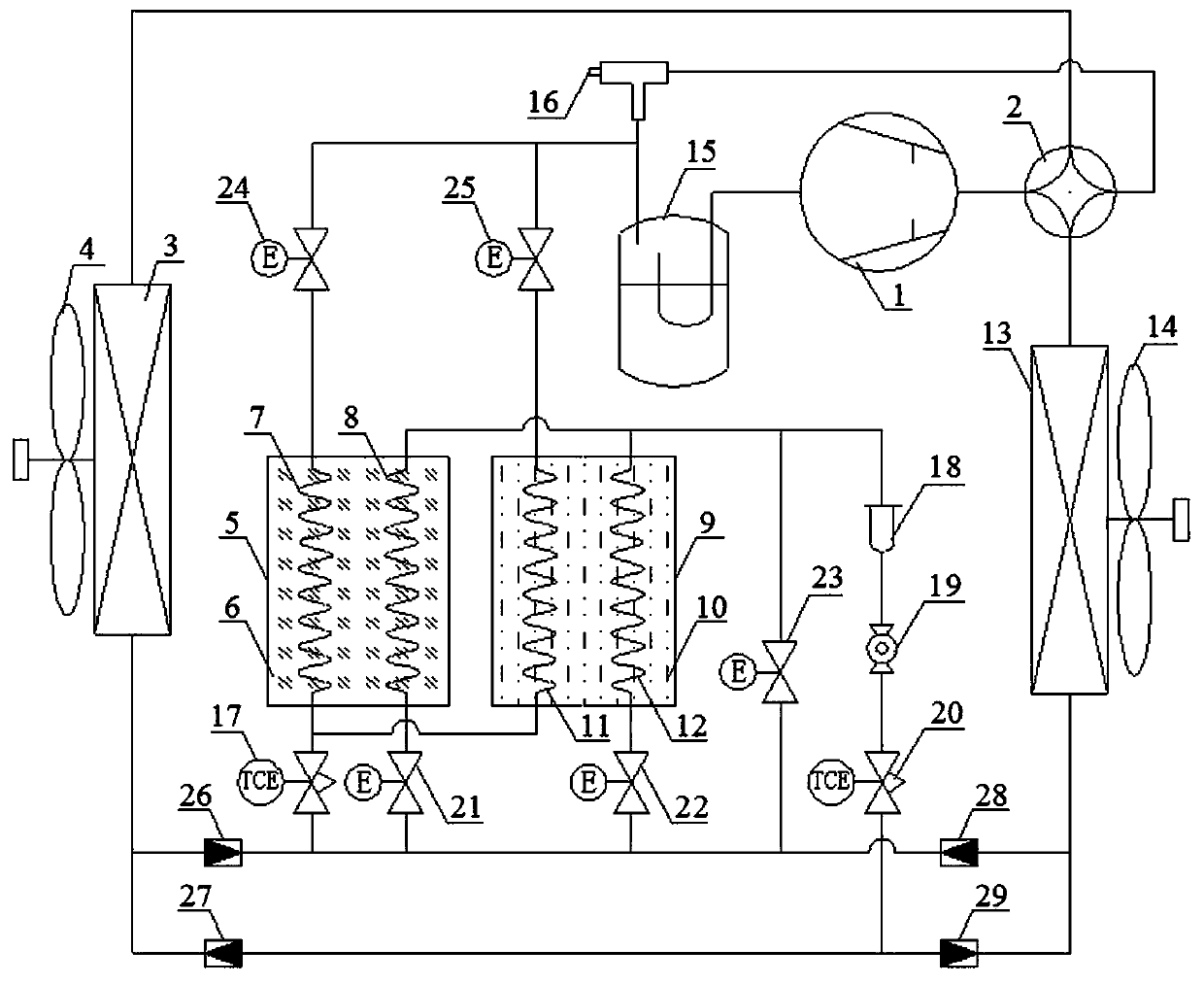

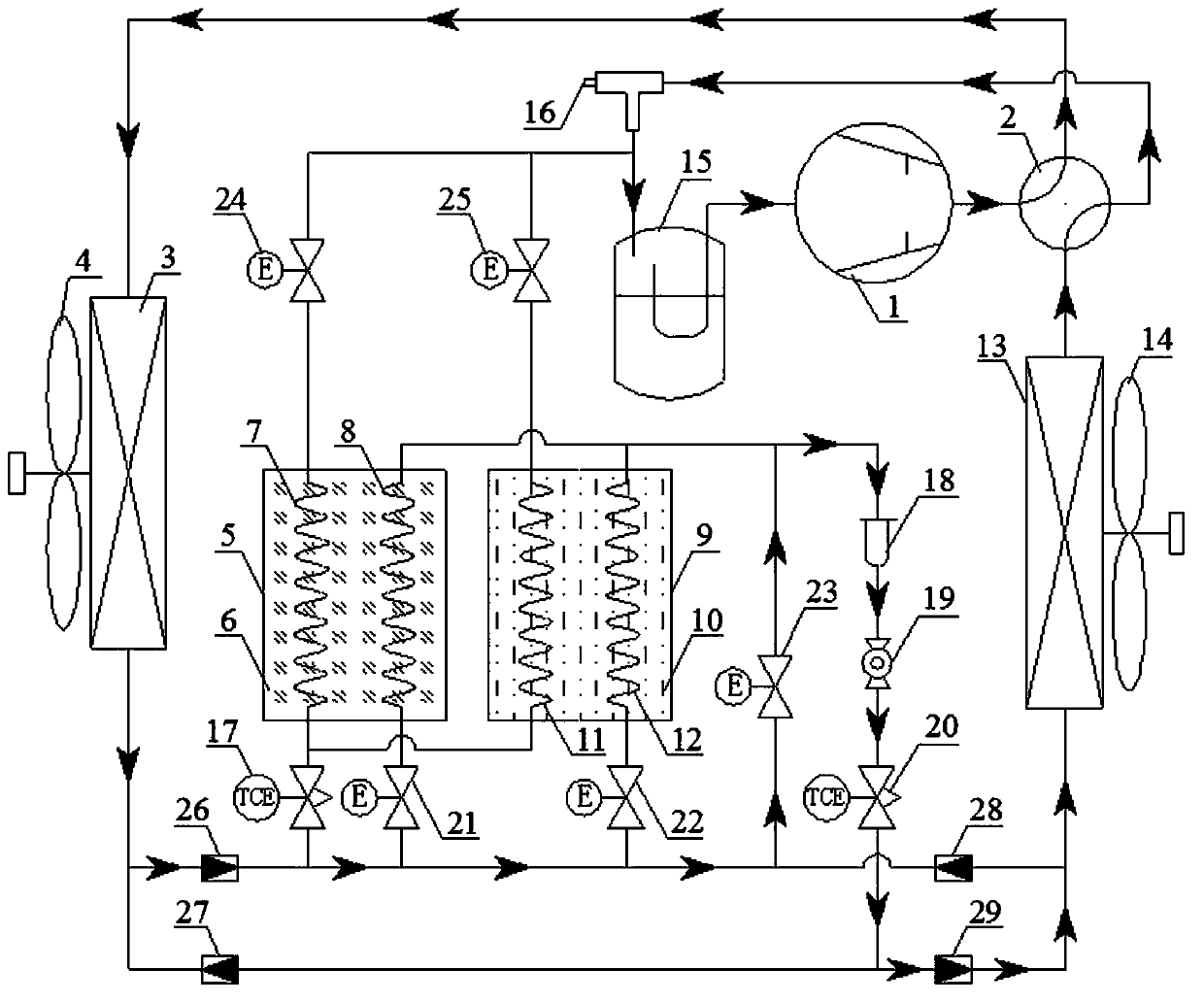

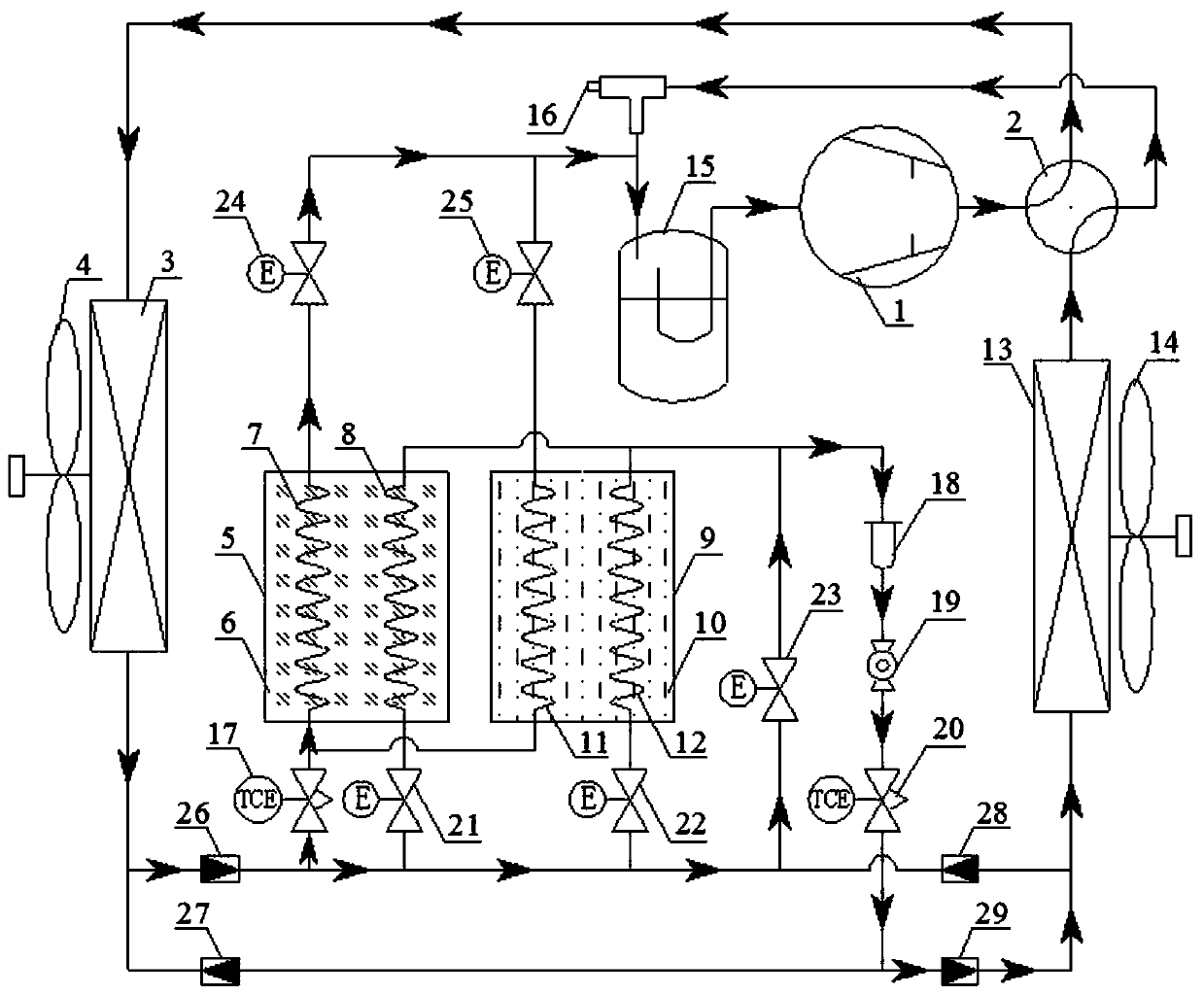

[0036] Such as figure 1As shown, the present invention provides an energy storage type high-efficiency air-cooled heat pump unit, including a refrigeration compressor 1, a four-way reversing valve 2, an outdoor side heat exchanger 3, an outdoor side fan 4, a cold storage device 5, and a phase change cold storage medium 6. Evaporation coil for cold storage 7, recooling coil for cold storage 8, heat accumulator 9, phase change heat storage medium 10, evaporation coil for heat storage 11, recooling coil for heat storage 12, indoor heat exchange device 13, indoor side fan 14, gas-liquid separator 15, evaporation pressure regulating valve 16, expansion valve for energy storage 17, dry filter 18, observation mirror 19, main road expansion valve 20, first solenoid valve 21, second Solenoid valve 22, the 3rd solenoid valve 23, the 4th solenoid valve 24, the 5th solenoid valve 25, the first check valve 26, the second check valve 27, the 3rd check valve 28, the 4th check valve 29 and C...

Embodiment 2

[0039] The refrigeration compressor 1 described in this embodiment is a fixed-frequency refrigeration compressor, the outdoor heat exchanger 3 and the indoor heat exchanger 13 are finned tube heat exchangers, the outdoor fan 4 and the indoor fan 14 are variable frequency fans, The evaporating pressure regulating valve 16 is a proportional regulating valve controlled by the pre-valve pressure, which is a direct-acting evaporating pressure regulating valve, the expansion valve 17 for energy storage and the main expansion valve 20 are manual expansion valves, and the phase change cold storage medium 6 And the phase change thermal storage medium 10 is a solid-liquid phase change material and a liquid-gas phase change material. Other structures are the same as in Embodiment 1.

Embodiment 3

[0041] The refrigeration compressor 1 described in this embodiment is a variable speed refrigeration compressor, the outdoor heat exchanger 3 and the indoor heat exchanger 13 are stacked heat exchangers, the outdoor fan 4 and the indoor fan 14 are adjustable fans, The evaporating pressure regulating valve 16 is a proportional regulating valve controlled by the pre-valve pressure. It is a relay type evaporating pressure regulating valve, and the expansion valve 17 for energy storage and the main expansion valve 20 are choke expansion valves and phase change cold storage. The medium 6 and the phase change thermal storage medium 10 are solid-solid phase change materials and solid-gas phase change materials. Other structures are the same as in Embodiment 1.

[0042] Example 3

[0043] The refrigeration compressor 1 described in this embodiment is a two-stage refrigeration compressor, the outdoor side heat exchanger 3, the indoor side heat exchanger 13 are parallel flow heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com