Motor rotor punching plate for deep groove type three-groove continuous structure

A motor rotor, deep groove technology, applied in the magnetic circuit shape/style/structure, asynchronous induction motor, electric components, etc., can solve the impact of material utilization and motor power density, adverse effects of motor noise, easy to generate burrs, etc. problems, to achieve the effect of improving material utilization, reducing rotor copper consumption, and reducing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

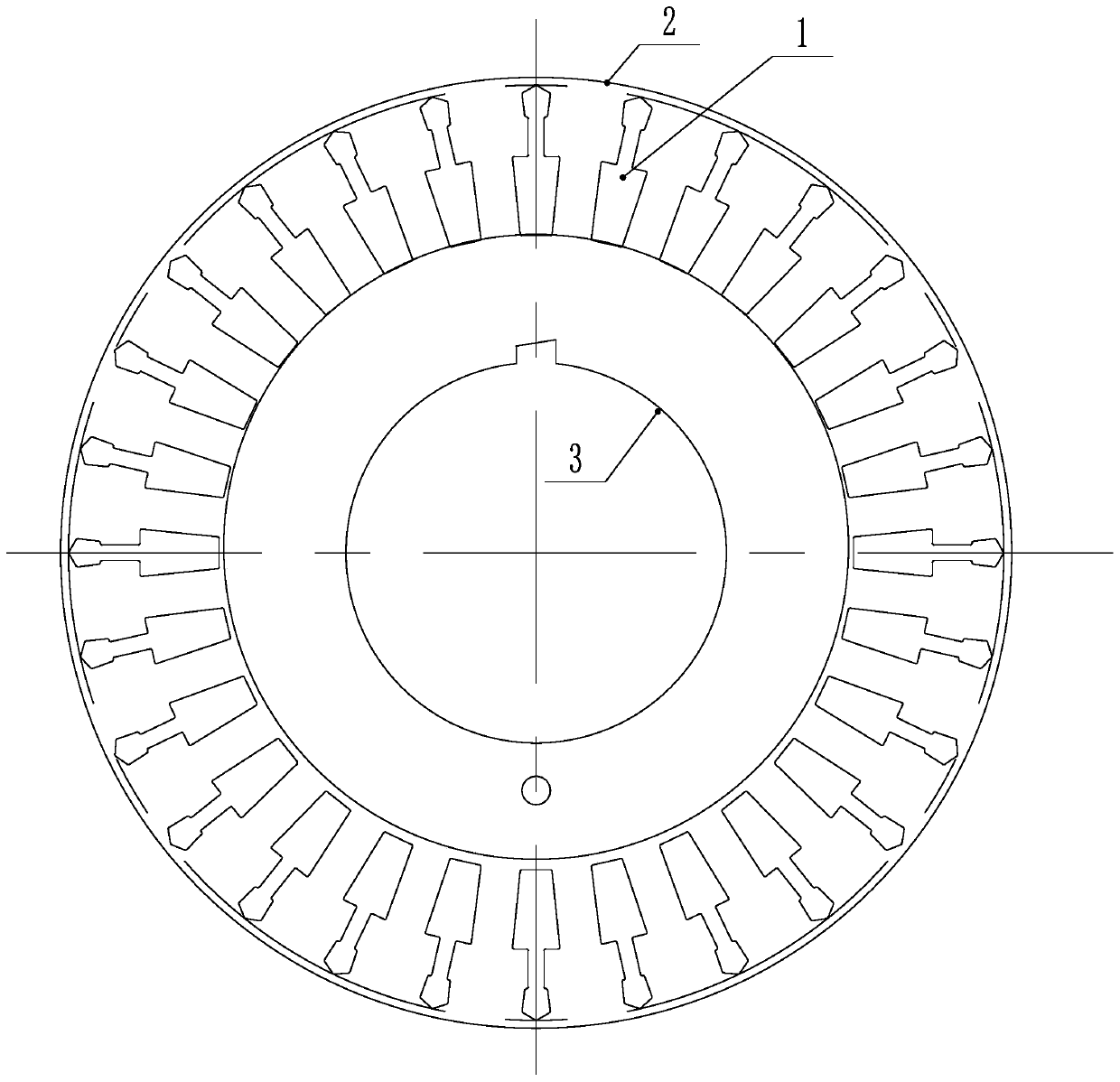

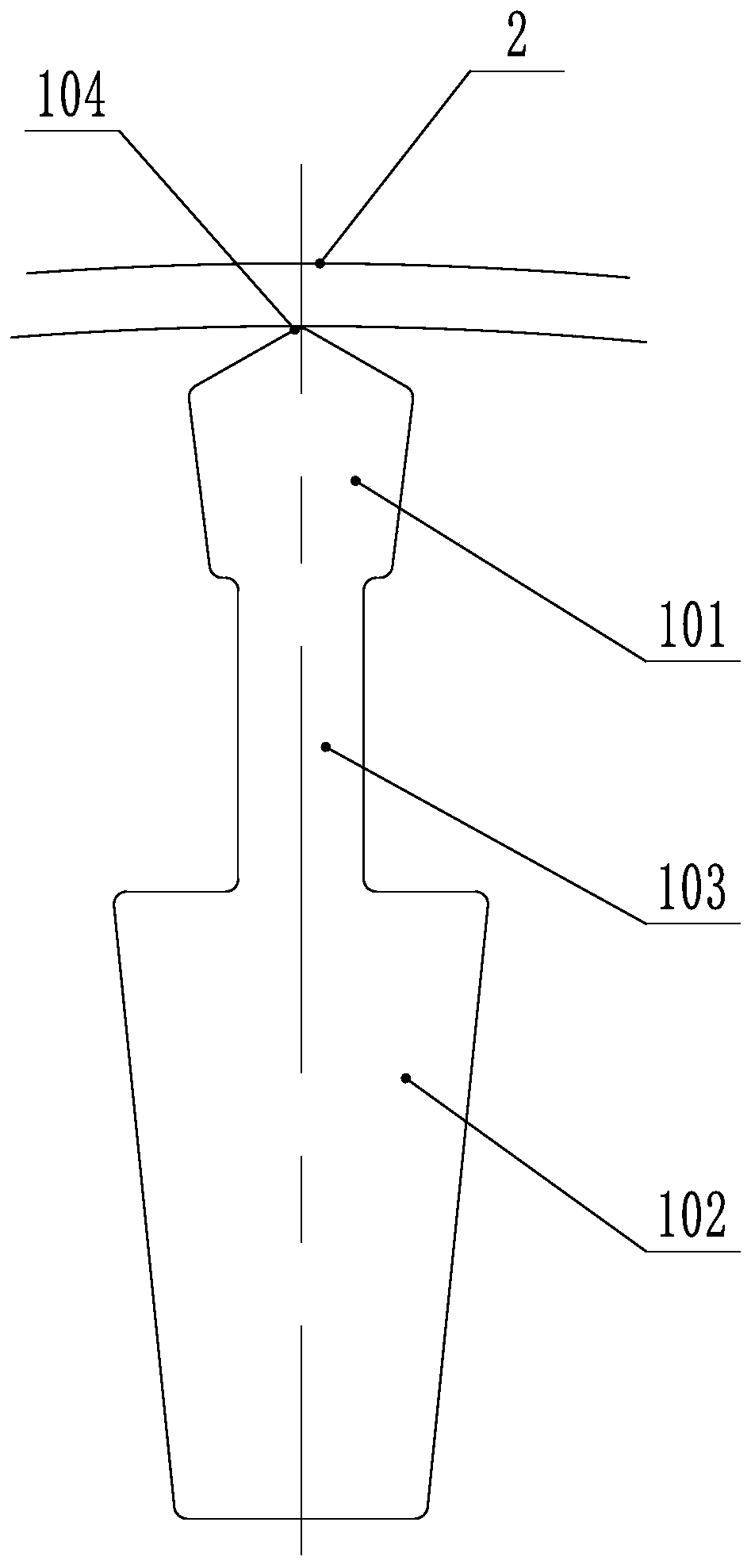

[0018] Such as Figure 1-2 As shown, a motor rotor punching sheet with a deep-groove three-slot continuous structure has punching grooves 1 evenly distributed around the rotor punching sheet. The punching grooves 1 are symmetrical according to their radial centerlines. The slender shape of the groove-type three-groove continuous structure, including the first groove part 101 located on the radially outer side, the second groove part 102 located on the radially inner side, and the first groove part 101 and the second groove part 102 pass through the bottleneck in the middle The connecting grooves 103 in the shape of the first groove are connected, the first groove 101 is a polygonal structure, the connecting groove 103 is a rectangular structure, the cross-sectional area of the second groove 102 is larger than that of the first groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com