Preparation device for coal water slurry additive

A technology for preparing devices and additives, which is applied in cleaning devices, transportation and packaging, sieves, etc., can solve the problems of cumbersome processes, reduce production efficiency, increase processing time, etc., to reduce process procedures, ensure water absorption performance, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

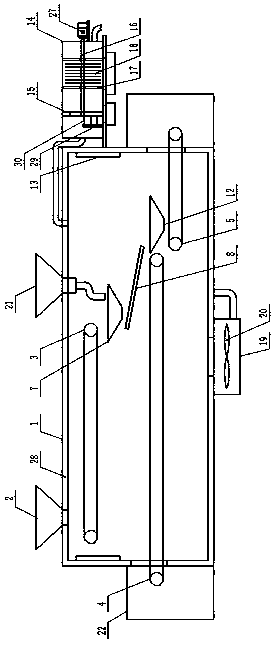

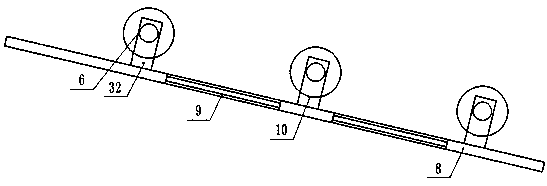

[0014] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , a preparation device for a coal-water slurry additive provided by the present invention is now described, including a drying box 1, a first feeding funnel 2 is provided at the top of the drying box 1, and a There is a first conveying mechanism 3, the inner cavity of the drying box 1 is located below the position of the first conveying mechanism 3, and a second conveying mechanism 4 is provided, and the inner cavity of the drying box 1 is located below the position of the second conveying mechanism 4, a third conveying mechanism 5 is arranged below the position, and a grinding mechanism 6 is arranged between the discharge end of the first conveying mechanism 3 and the feeding end of the second conveying mechanism 4, and the grinding mechanism 6 is formed by the first set The inclined material guide plate 8 provided directly below the bin 7 and the first collecting bin 7, the vibrating filter screen 9 prov...

Embodiment 2

[0015] Example 2: see figure 1 , figure 2, the preparation device for a kind of coal-water slurry additive provided by the present invention is described now, and described first conveying mechanism 3, the second conveying mechanism 4, the 3rd conveying mechanism 5 are all existing device belt conveyors, and all are made of A group of rotating rollers, a conveyor belt and a driving motor set between the rotating rollers. The material conveying direction of the first conveying mechanism 3 is the same as that of the third conveying mechanism 5. The material conveying direction of the first conveying mechanism 3 The conveying direction is opposite to the material conveying direction of the second conveying mechanism 4, and a first feed opening is opened on the top of the drying box 1 and directly above the position corresponding to the feed end of the first conveying mechanism 3, and the first feed inlet is The feed funnel 2 is arranged corresponding to the position of the firs...

Embodiment 3

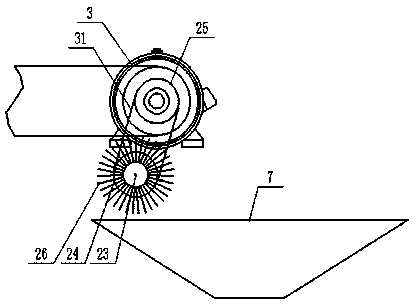

[0016] Embodiment 3: see figure 1 , figure 2 , image 3 , Figure 4 , the preparation device for a kind of coal-water slurry additive provided by the present invention will be described now, the first collection bin 7 and the second collection bin 12 are both hollow circular frustum-shaped and both upper and lower ends are open, and the first collection bin The cross-sectional area of the upper port of the feed bin 7 and the second collection bin 12 is larger than the cross-sectional area of the lower port and is set in an inverted trapezoidal shape. The first collection bin 7 is located below the discharge end of the first conveying mechanism 3, so Below the position of the first conveying mechanism 3 and above the position of the first collecting bin 7, a rotating shaft 23 is provided. One end of the rotating shaft 23 in the longitudinal direction is covered with a driven pulley 24. The driving motor of the drive motor is arranged near the position of the first colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com