Method for preparing enamel arc plate with radius r>3000mm

A circular arc plate and enamel technology, which is applied in the field of architectural decoration, can solve the problems of easy cracking, bursting, and inability to guarantee the radian, and achieve the effects of improving the yield, reducing production costs and economical production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

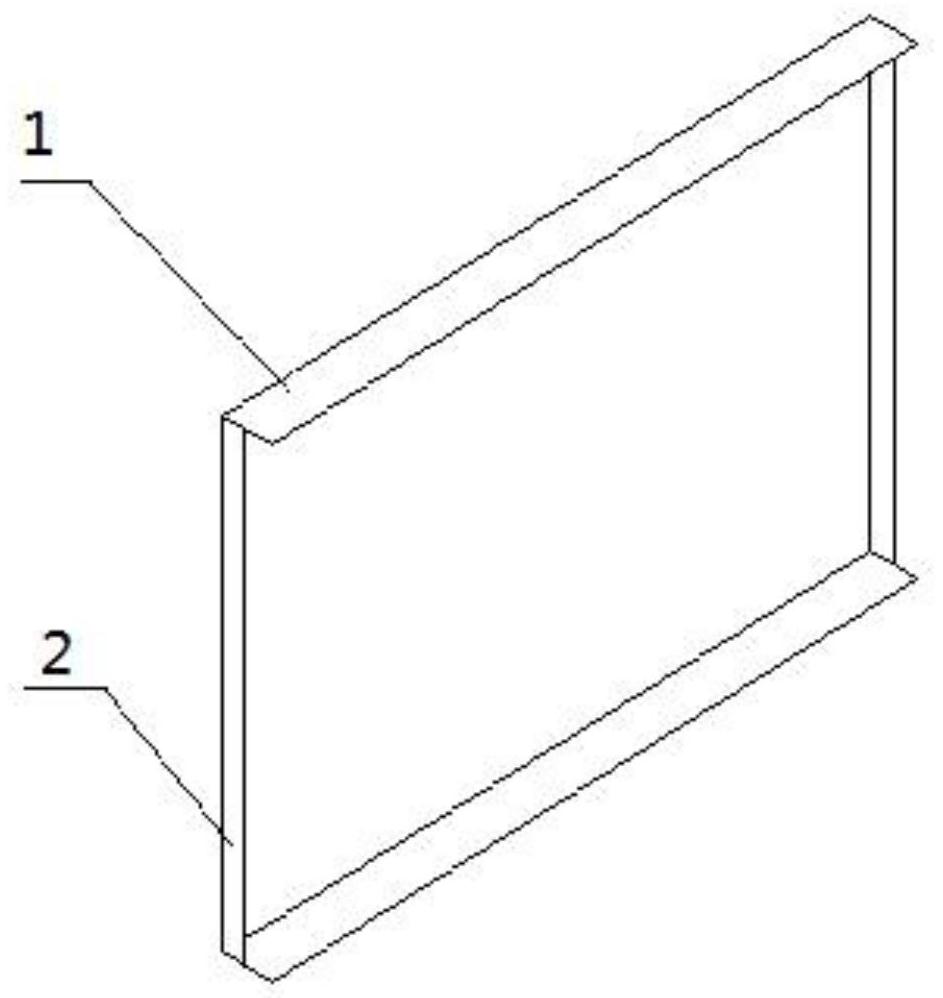

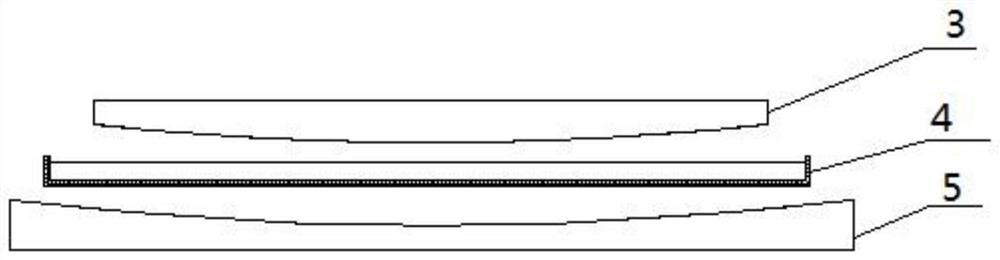

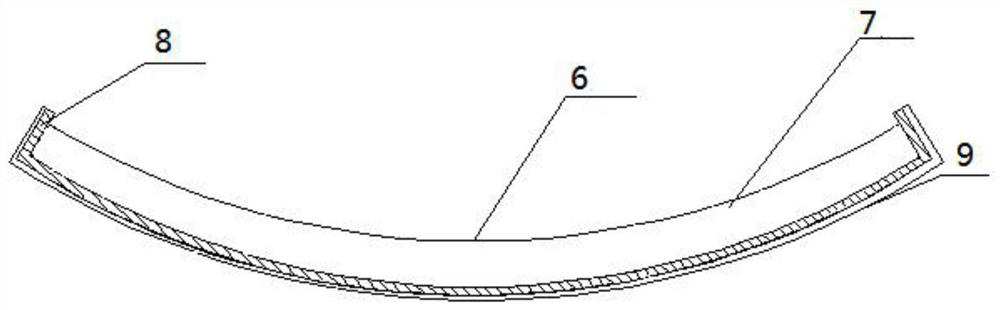

[0062] The method for preparing an enamel circular arc plate with a radius of 4000 mm and a radius r>3000 mm comprises the following steps: selecting enameled steel with a carbon content of less than 0.008% and a thickness of 1.5 mm as a plate, laser cutting the required size; bending the corners of the plate, The vertical hem height is 6mm, and the transverse hem height is 22mm; the corners of the plate are fully welded; welding and grinding; the surface of the plate is degreased, pickled, and dried at a drying temperature of 160°C and a drying time of 22 minutes; select moisture The glaze with a content of 30% is sprayed on both sides of the board by wet spraying. The thickness of the bottom glaze is 80um, and the thickness of the surface glaze is 80um; the firing temperature is 800℃, and the firing time is 4min; surface coating; crimping the aluminum honeycomb core; molded to form a circular arc plate, then crimping the galvanized steel plate, and packing it into a warehouse...

Embodiment 2

[0064] The method for preparing an enamel circular arc plate with a radius of 5000 mm and a radius r>3000 mm comprises the following steps: selecting enameled steel with a carbon content of less than 0.008% and a thickness of 1.6 mm as a plate, laser cutting the required size; bending the corners of the plate, The vertical hem height is 6mm, and the transverse hem height is 22mm; the corners of the plate are fully welded; welding and grinding; the surface of the plate is degreased, pickled, and dried at a drying temperature of 160°C and a drying time of 22 minutes; select moisture The glaze with a content of 40% is sprayed on both sides of the board by wet spraying method. The bottom glaze spraying thickness is 90um, and the surface glaze spraying thickness is 90um; high temperature firing, firing temperature is 820 ℃, firing time is 4min; surface coating; crimping aluminum honeycomb core; molded to form a circular arc plate; crimping galvanized steel plate; packing into storag...

Embodiment 3

[0066] The method for preparing an enamel circular arc plate with a radius of 7000 mm and a radius r>3000 mm comprises the following steps: selecting enameled steel with a carbon content of less than 0.008% and a thickness of 1.7 mm as a plate, laser cutting the required size; bending the corners of the plate, The vertical hem height is 14mm, and the transverse hem height is 28mm; the corners of the plate are fully welded; welding and grinding; the surface of the plate is degreased, pickled, and dried at a drying temperature of 180°C and a drying time of 28 minutes; select moisture The glaze with a content of 50% is sprayed on both sides of the board by wet spraying. The thickness of the bottom glaze is 120um, and the thickness of the surface glaze is 120um; high temperature firing, firing temperature is 840 ℃, firing time is 4.5min; surface coating; crimping the aluminum honeycomb core; molding to form a circular arc plate, crimping the galvanized steel plate; packing into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com