Bridge crane with safer utilization and wider applicability

An overhead crane, a technology of applicability, which is applied in the directions of walking overhead cranes, cranes, and traveling mechanisms, can solve the problems of large construction site impact, limited lifting area, and falling walking frames, and achieves safe operation and lifting. The effect of increasing the area and enhancing the adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

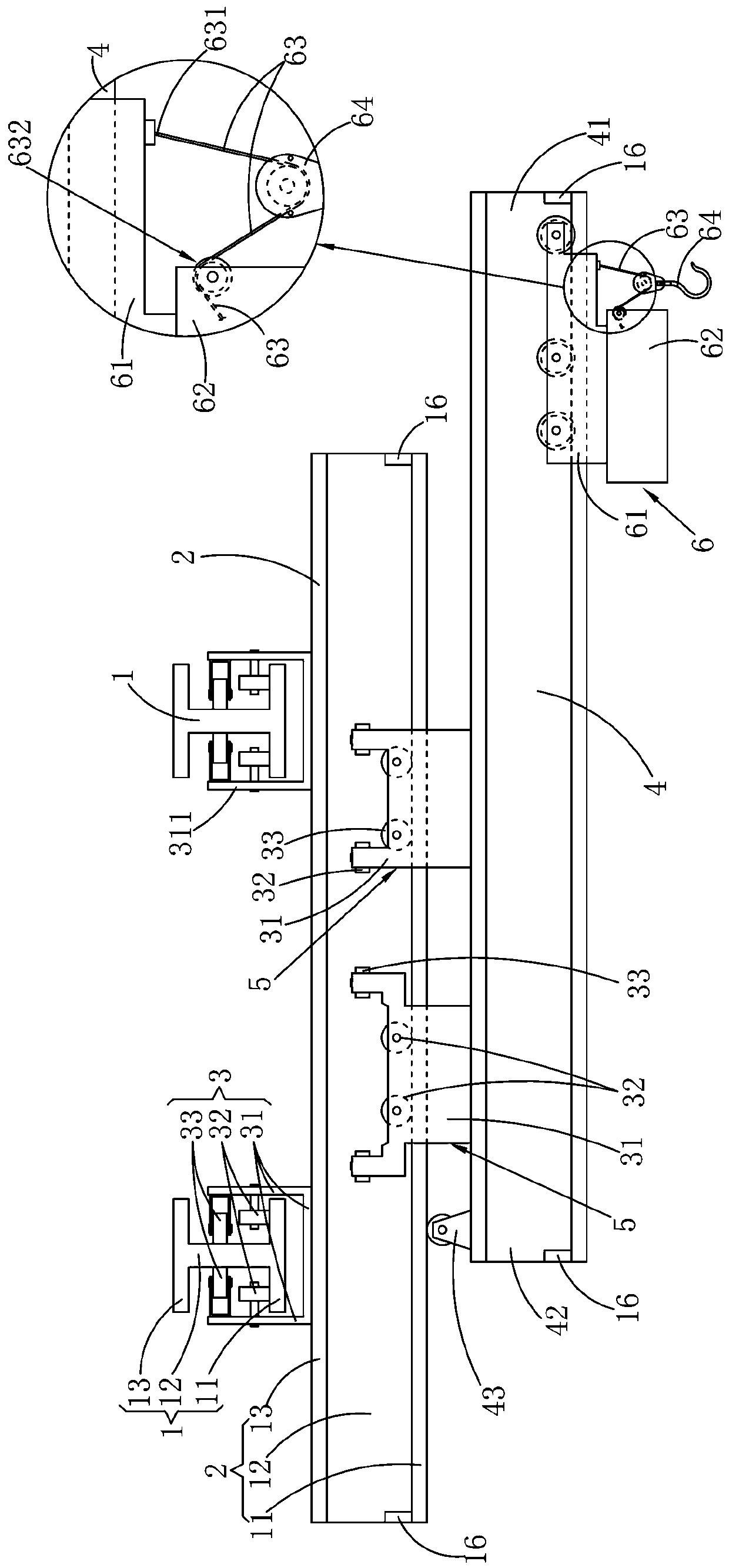

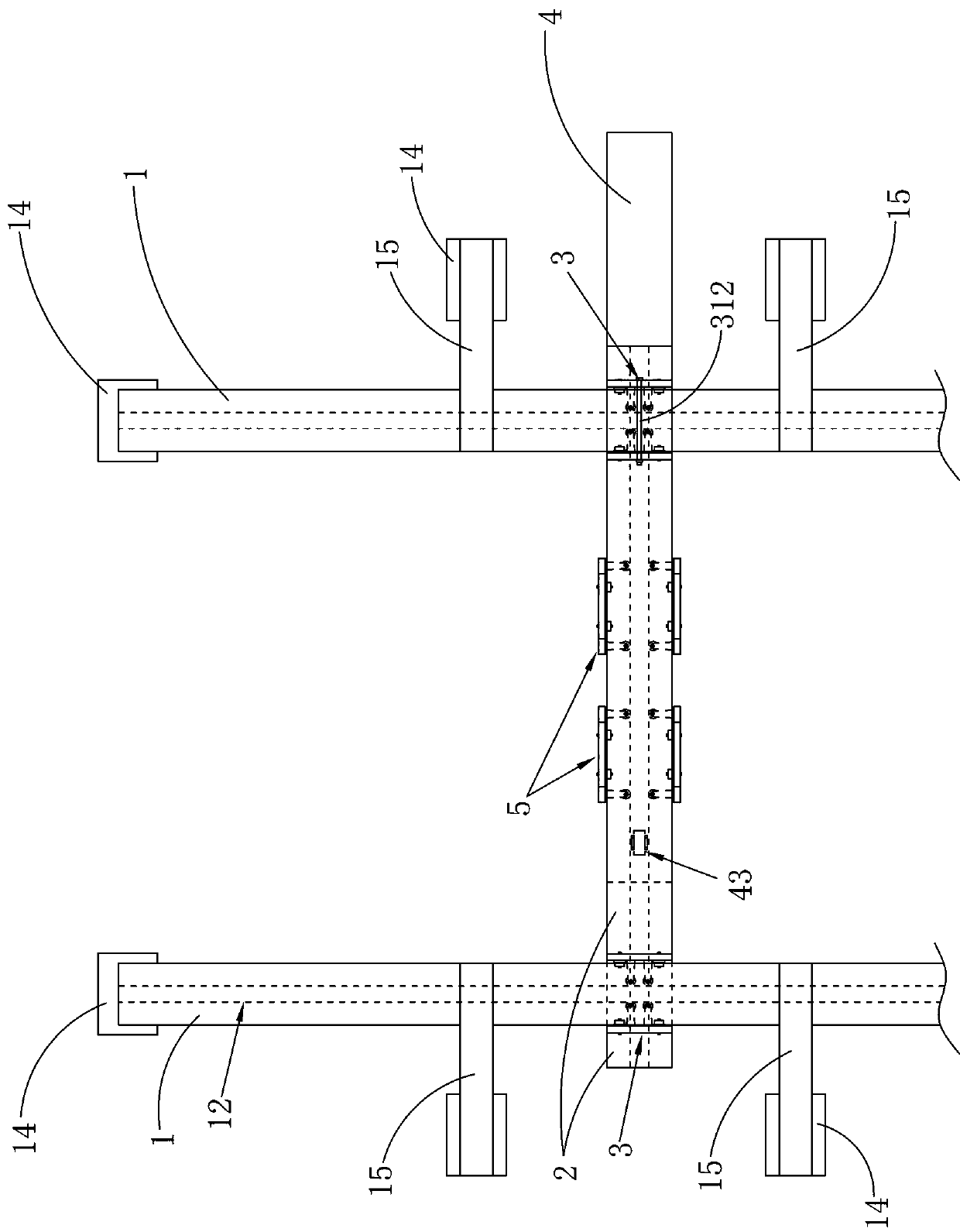

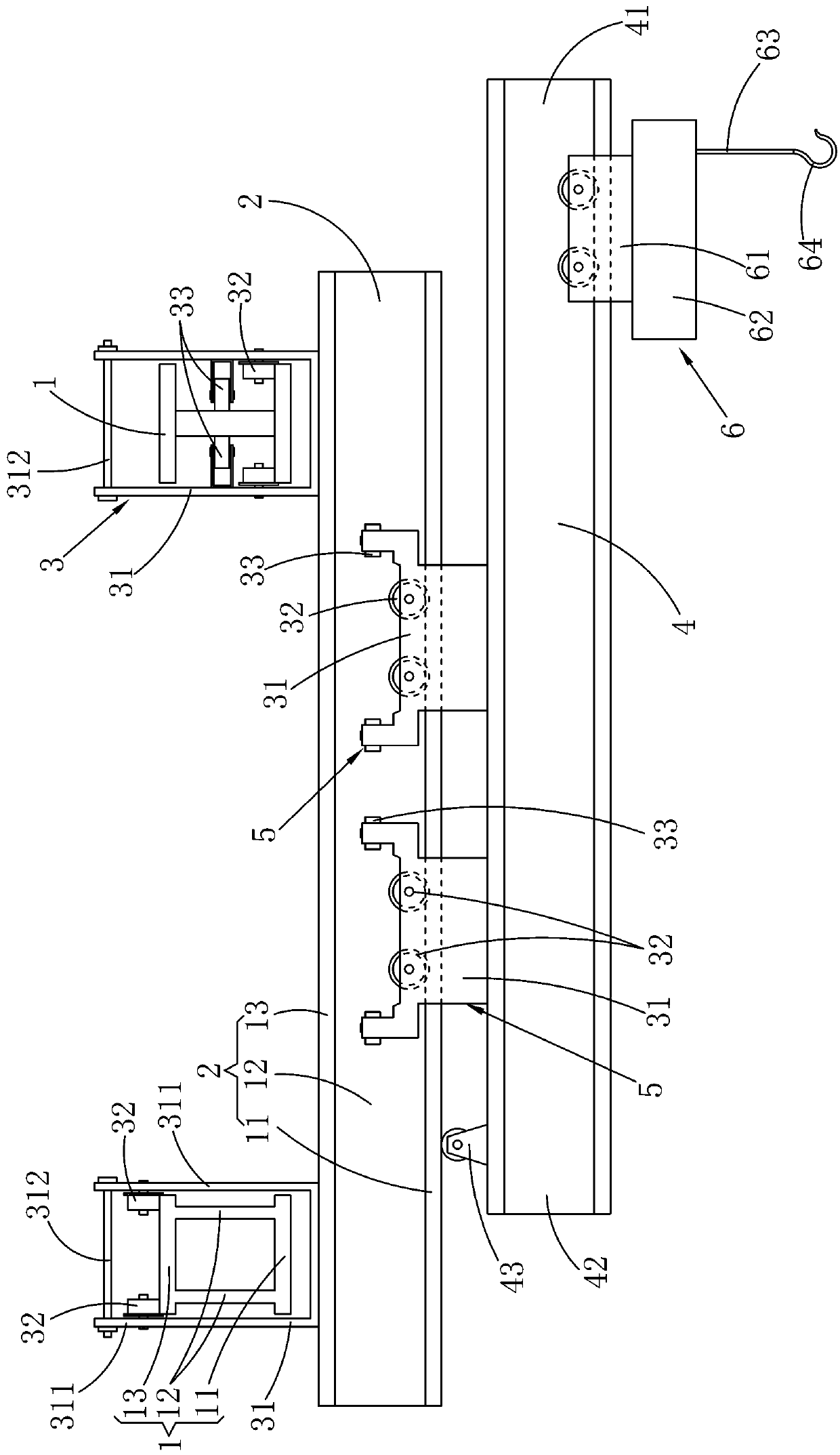

[0025] refer to figure 1 , figure 2 , a bridge crane with safer use and wider applicability, including a longitudinal main girder 1 and a cross girder 2, both of which are composed of a bottom plate 11, a connecting wall plate 12 and a top plate 13 which are sequentially fixed and connected as a whole, The cross-sections of the longitudinal main beam 1 and the cross beam 2 are both H-shaped; the longitudinal main beam 1 is fixedly assembled on the supporting carrier (such as figure 2 As shown, the support carrier is preferably a cement support column 14 standing on the ground, a metal skeleton 15 above the longitudinal main beam 1, etc.), the beam 2 is equipped with a longitudinal walking frame 3, and the beam 2 slides and is assembled on the Below the longitudinal girder 1.

[0026] Continue to refer to figure 1 , figure 2 , the above beam 2 is equipped with an extension beam 4, the extension beam 4 slides and is assembled under the beam 2 through the traverse frame 5,...

Embodiment approach 2

[0032] refer to image 3 , Figure 4 The installation frame 31 of the above-mentioned longitudinal walking frame 3 is U-shaped, and the two side plates 311 of the installation frame 31 are respectively extended upwards from the two sides of the above-mentioned longitudinal main beam 1, and the traveling wheels 32 of the above-mentioned longitudinal walking frame 3 are rotated with a fixed axis. Assembled on the side plate 311 , the traveling wheel 32 travels on the top surface of the top plate 13 of the longitudinal main beam 1 . The longitudinal traveling frame 3 and the top of the longitudinal main girder 1 slide, so that the load of the longitudinal traveling frame 3 is carried by the longitudinal main girder 1 as a whole (refer to figure 1 , when the traveling wheels 32 are walking on the bottom of the longitudinal girder 1, after the bottom plate 11 bears the load, the acting force on the connecting wall plate 12 is a downward pulling force, and the acting force of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com