Advanced closing structure of basement roof post-pouring strip and construction method

A technology for a basement roof and a closed structure is applied in the construction of the post-casting belt of the basement roof in advance of the closed structure, and the post-casting of the basement roof in the field of the pre-closed structure, which can solve the unreasonable structural design of the closed cover plate at the top of the post-cast belt, and the potential safety hazards. Construction difficulty and other problems, to achieve the effect of ensuring compactness and construction quality, and eliminating hidden dangers of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

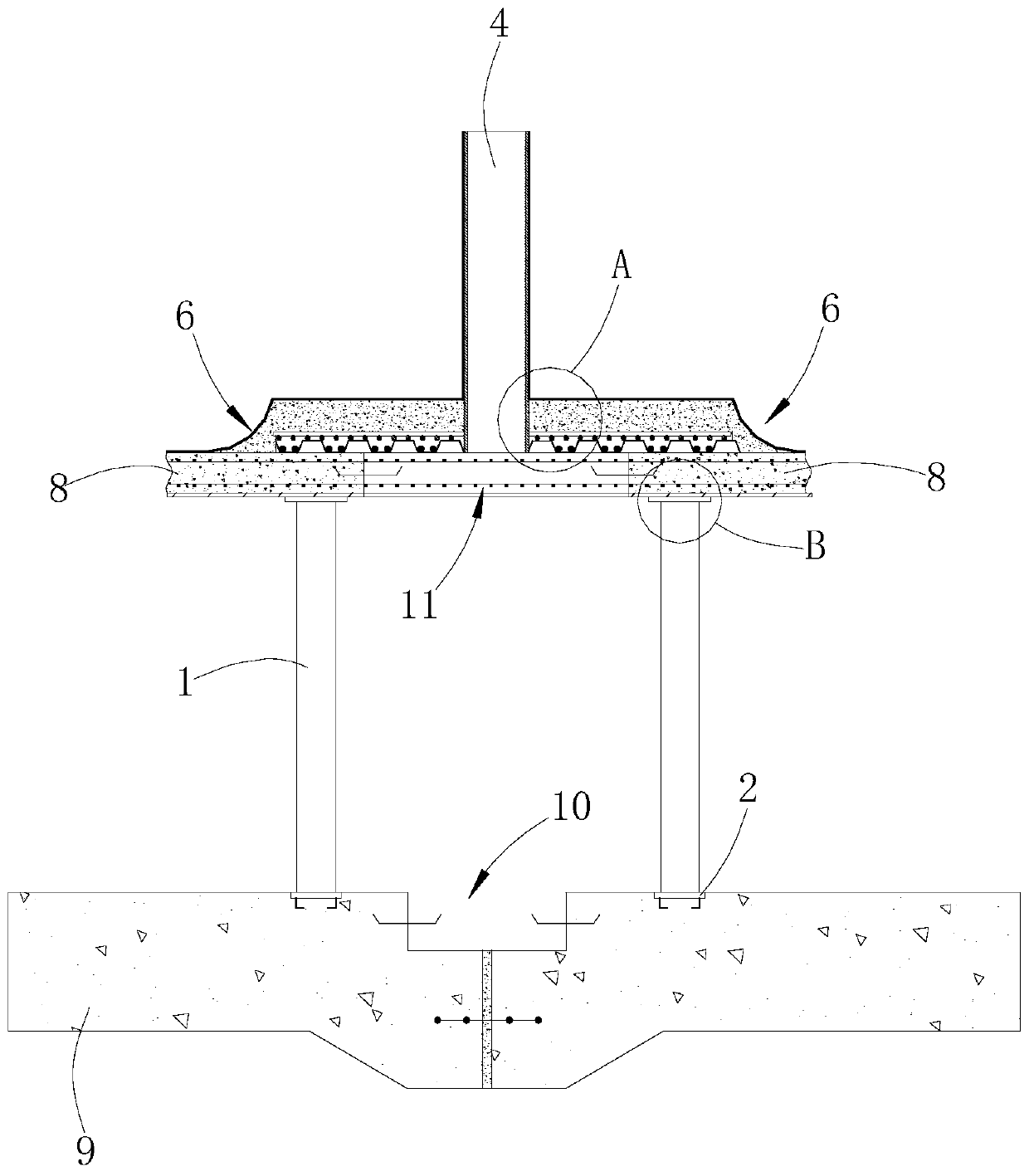

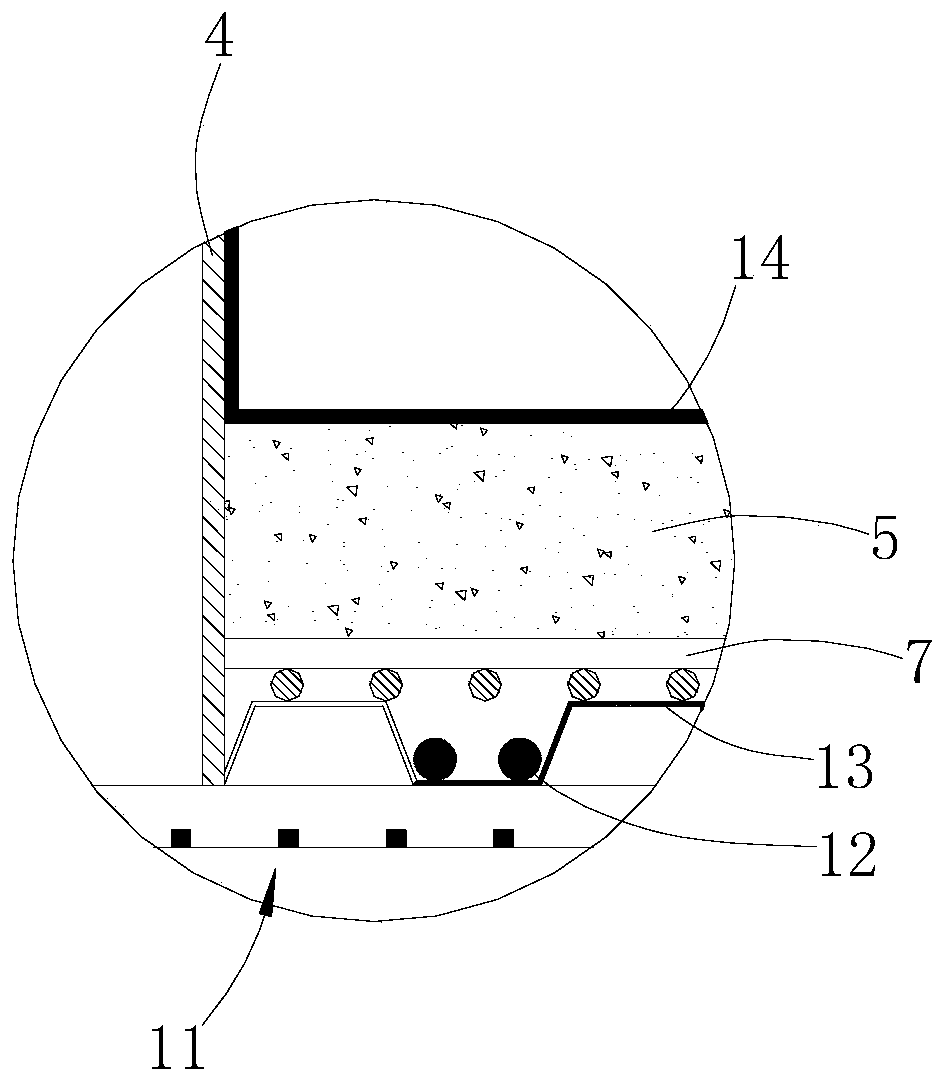

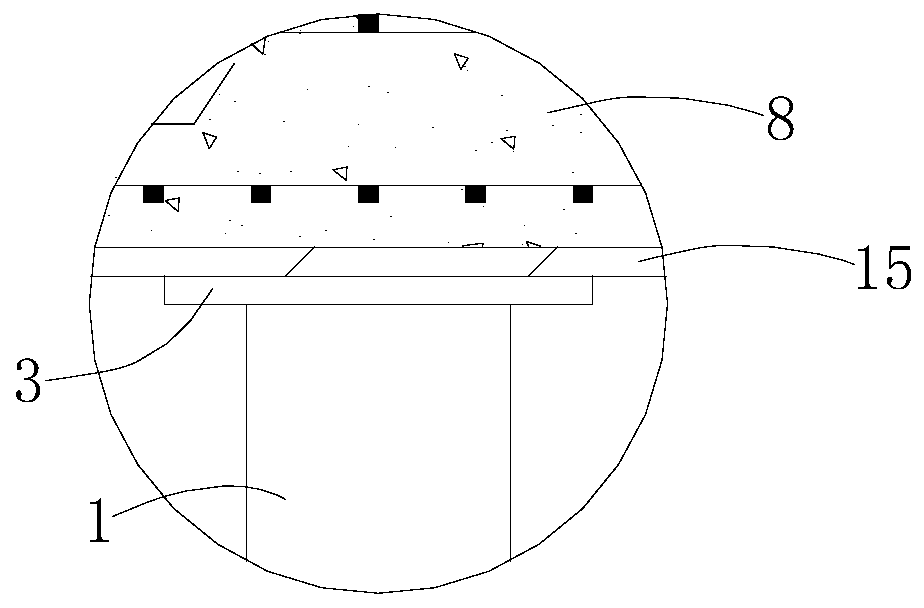

[0030] Such as Figures 1 to 3 shown

[0031] The post-casting tape early closure structure of the basement roof includes a coiled material waterproof layer 14, a profiled steel plate 13, a cover plate steel bar 7, a cast-in-place concrete cover plate layer 5, a steel pipe 4 and several reinforcement bars 12.

[0032] The profiled steel plate 13 is covered on the roof post-casting belt 11 between the basement roofs 8 on both sides, and the two ends of the profiled steel plate 13 are supported on the upper end surfaces of the basement roof 8 on both sides. Through holes, a number of reinforcing steel bars 12 are placed in parallel in the grooves on the upper surface of the profiled steel plate 13, the cover plate steel bar 7 covers the upper side of the profiled steel plate 13, and the cast-in-place concrete cover plate is formed on the upper side of the cover plate steel bar 7 Layer 5, the steel pipe 4 runs through the cast-in-place concrete cover layer 5, the cover plate rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com