Air inlet control method for oxygen-enriched hot blast stove

A control method and technology of oxygen-enriched hot air, applied in the combustion method, control combustion, furnace and other directions, can solve the problems of inaccurate temperature control, affecting the quality of iron-making products, and difficult temperature control, so as to ensure normal work and reduce control. Human use of temperature, effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

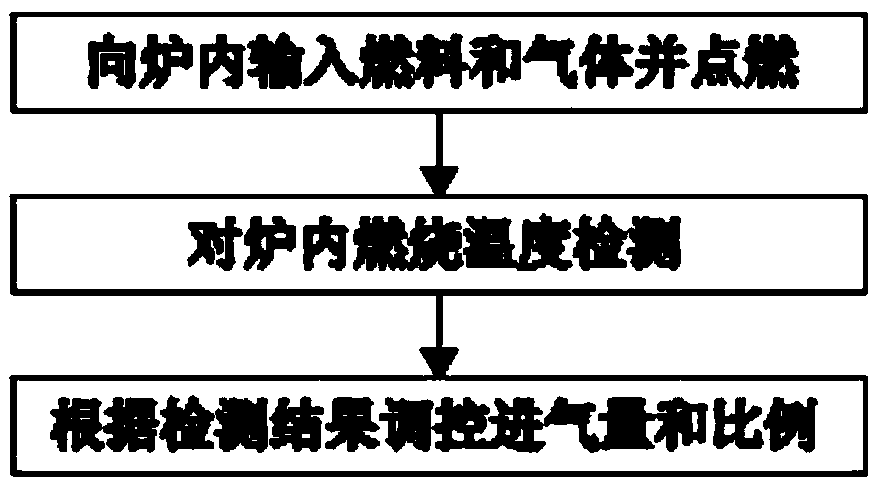

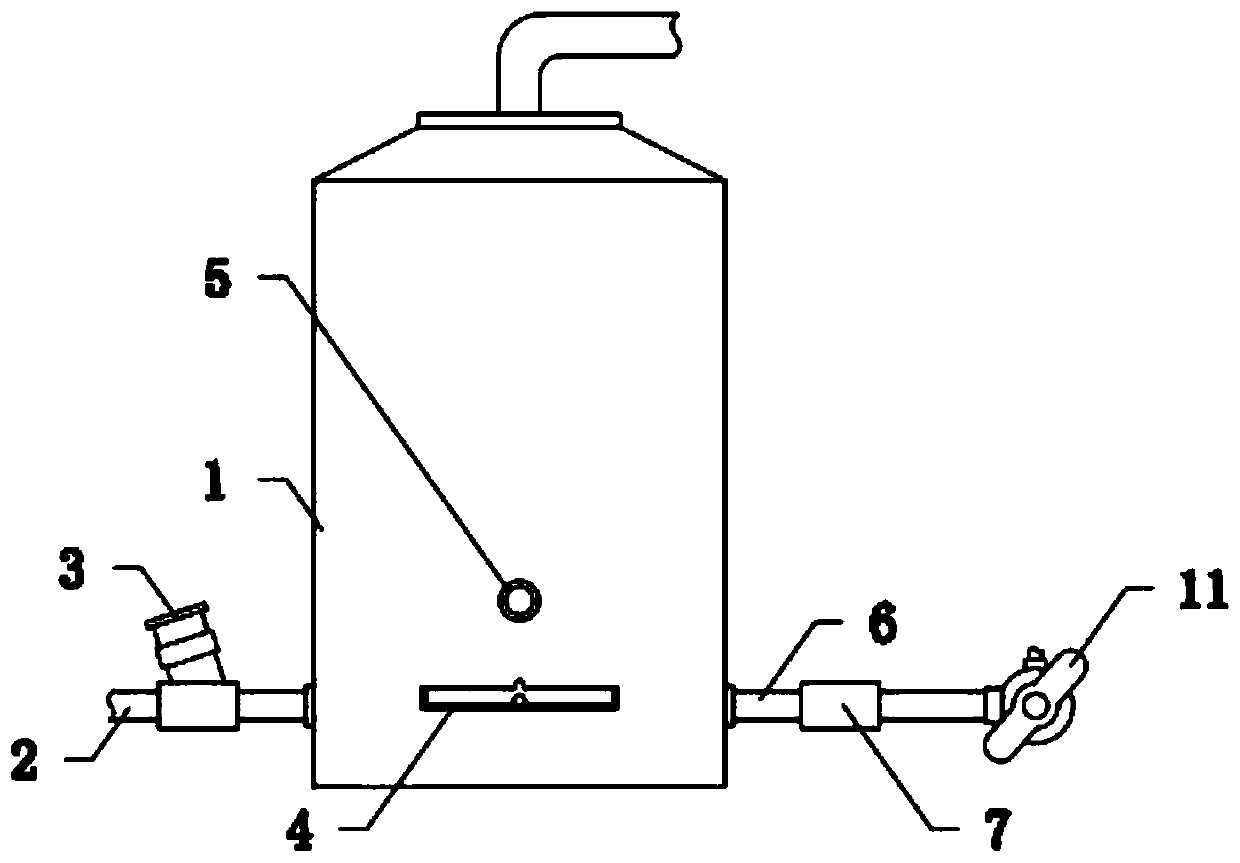

[0031] see Figure 1-3 , the present invention provides a technical solution: an air intake control method of an oxygen-enriched hot blast stove, the specific steps of the air intake control method of the oxygen-enriched hot blast stove are as follows:

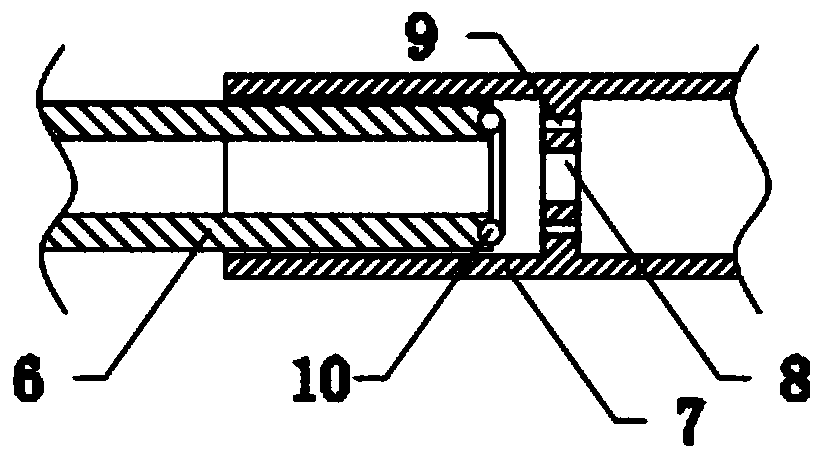

[0032] On the two side walls of the furnace body 1, the oxygen-enriched intake pipe 2 and the fuel inlet pipe 6 are installed symmetrically. Fuel, natural gas is used as fuel here, and natural gas enters the furnace body 1 through the fuel inlet pipe 6, and the gas inlet pipe 2 on the other side feeds gas with higher oxygen content into the furnace body 1;

[0033] A temperature detection device 5 is installed on the outer wall of the furnace body 1;

[0034] The air intake pipe 2 is connected to the air inlet 3 through a three-way pipe, and an auxiliary air inlet 4 is arranged on the side wall of the furnace body 1, and an opening and closing door is arranged on the auxiliary air inlet 4, which is usually closed. When the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com