A Porous Jet Burner Based on Internal and External Swirl to Promote Liquid Fuel Atomization

A technology of liquid fuel and porous jet, which is applied in the field of combustion, can solve the problems of high-efficiency, compact and controllable combustion technology that have not yet been developed, and achieve the effects of avoiding direct contact with the wall, promoting atomization and evaporation, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The purpose of this embodiment is achieved through the following technical solutions.

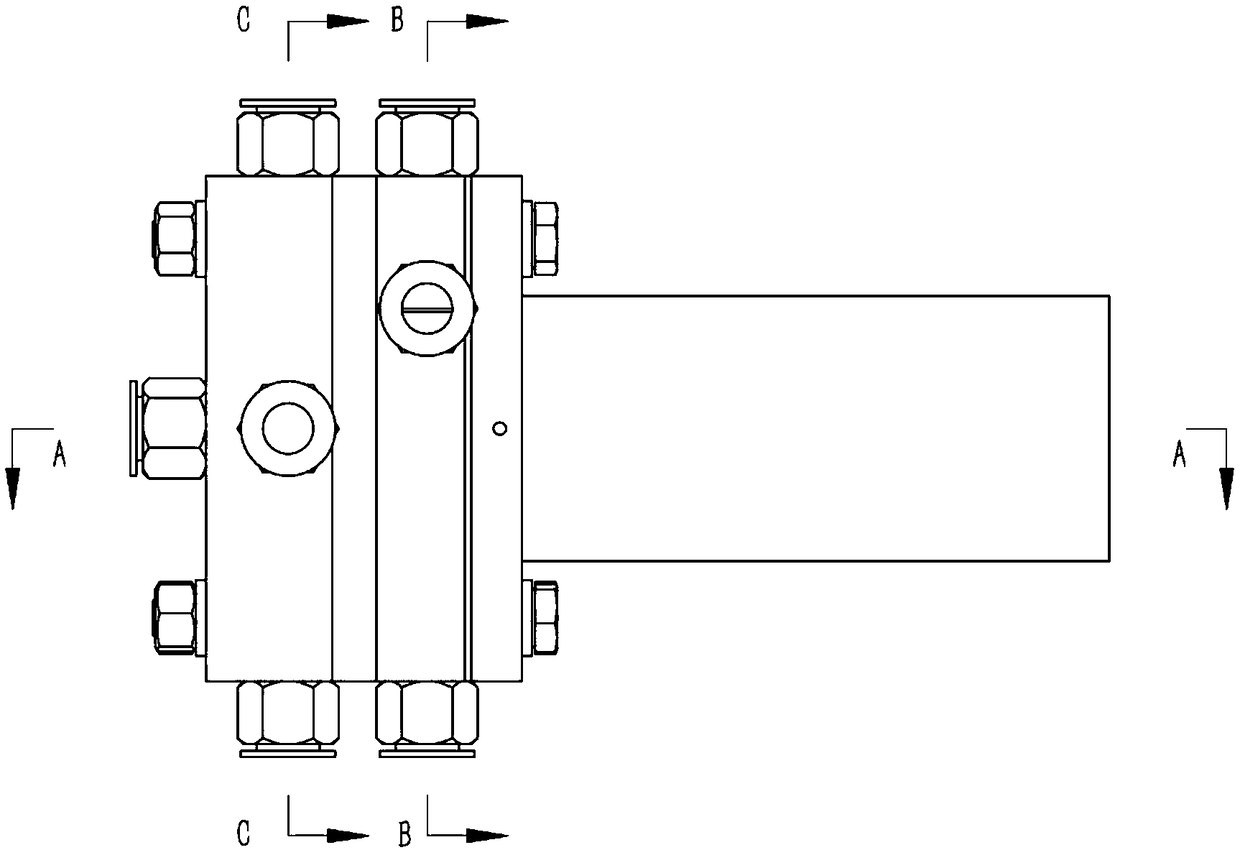

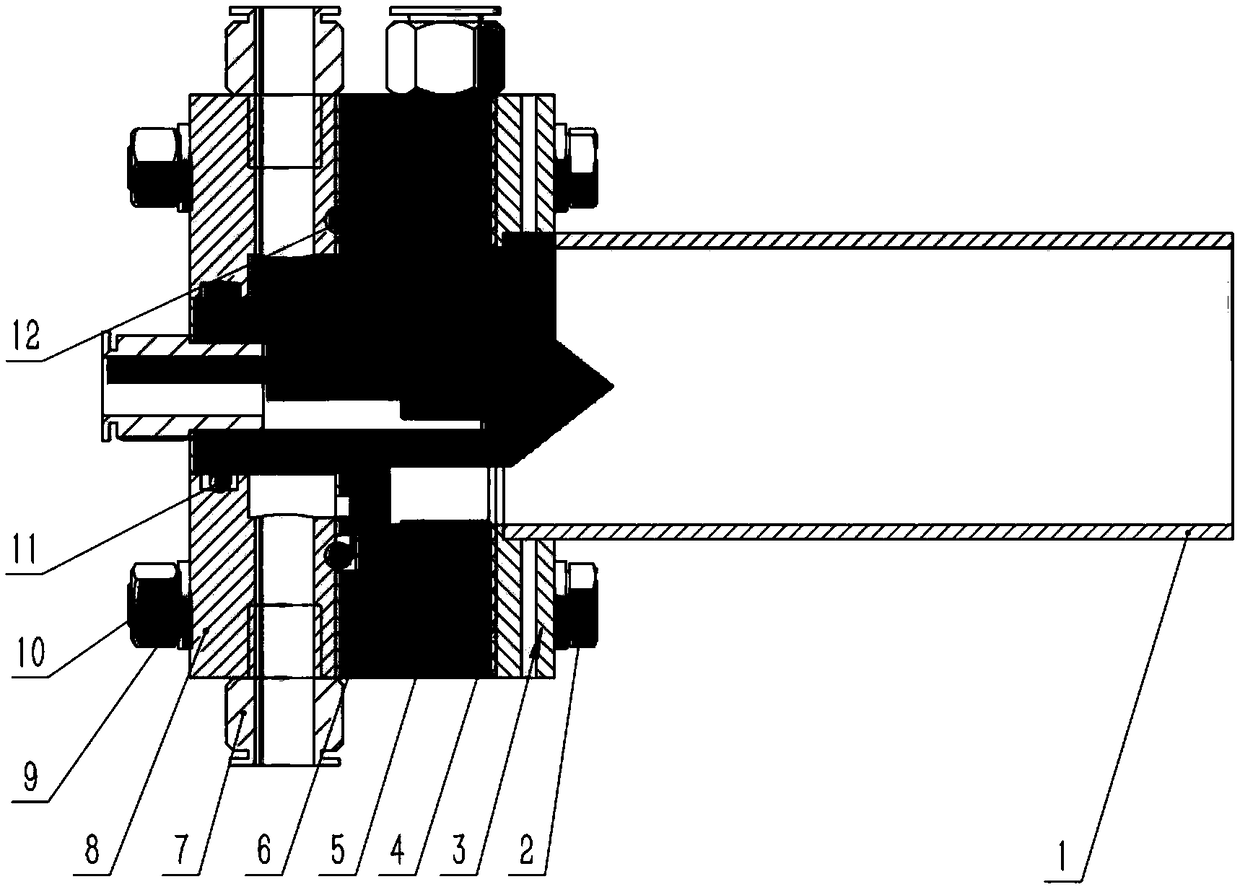

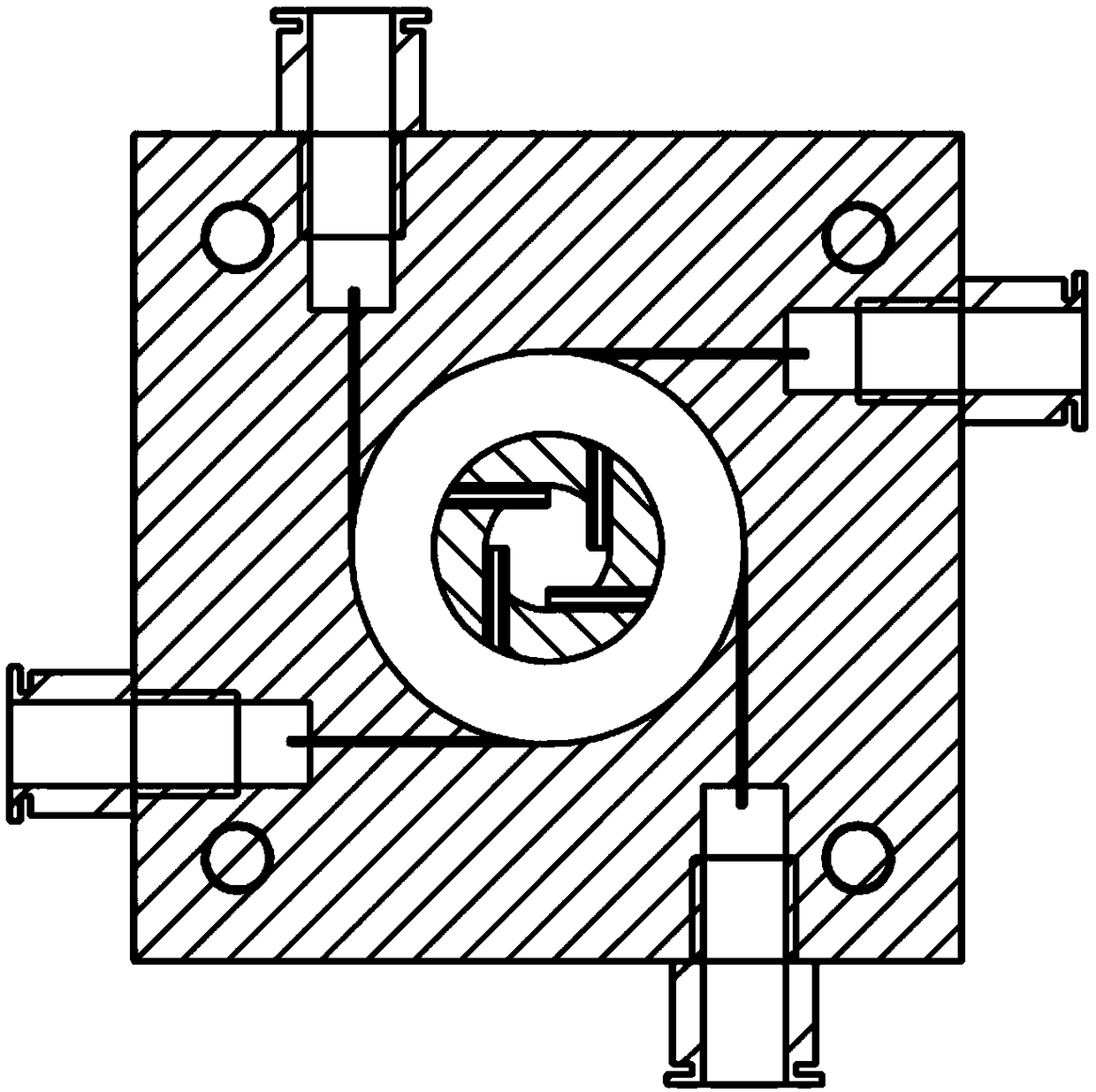

[0027] Such as figure 1 , 2 As shown, a porous jet burner based on internal and external swirl flow to promote liquid fuel atomization disclosed in this embodiment includes a quartz glass tube with an inner diameter of 48 mm), M6 hexagonal screws 2, front cover 3, and 0.5 mm thick copper gasket 4 , G1 / 8 quick pipe joint 7, back cover 8, gasket 9, M6 hex nut 10, small O-ring 11, large O-ring 12; also includes outer swirl block 5, jet-inner swirl block 6. The outer swirl block (5) has 4 tangential inlets tangent to the inner wall surface, the slit width of the tangential inlets is 0.5 mm, and has gas inlet holes corresponding to the 4 tangential inlets, so that the inlet The oxidant forms an external swirl close to the wall, such as the section at B-B image 3 shown. The jet-inner swirl block 6 has 4 evenly distributed inner swirl inlets with a width of 1mm, and the 4 evenly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com