Control method for vertical material conveyor based on sliding form adaptive robust control

A technology of sliding mode self-adaptation and transmission device, which is applied in the direction of self-adaptive control, conveyor control device, comprehensive factory control, etc. It can solve the problems of poor realization of position control, poor position control, and great influence on precision, etc. problems, to achieve high-precision control, weaken the phenomenon of trembling array, and enhance the effect of anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

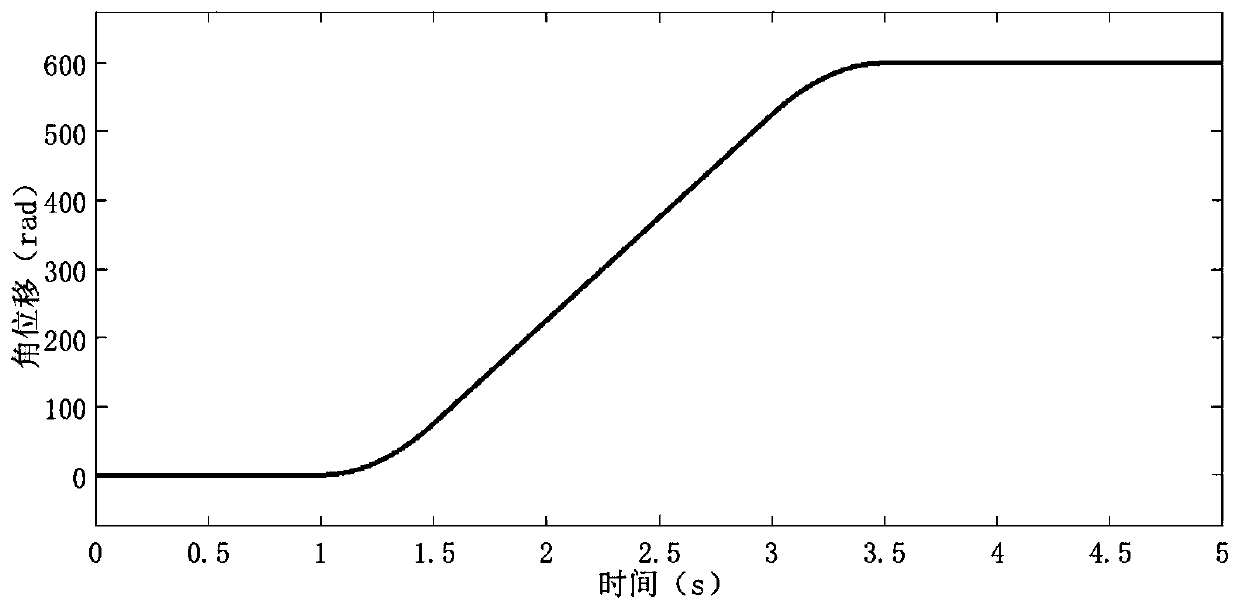

[0050] This embodiment takes the vertical material conveying device as the specific object, and the servo motor outputs torque according to the method of the present invention to control the vertical material conveying device to track according to the trajectory curve planned by the present invention.

[0051] The Smiulink module in the MATLAB software is used to carry the simulation environment of the position control of the vertical material conveying device, the control program is written according to the method of the present invention, the simulation time is set to 5s, and the simulation result curve is detected in the scope module.

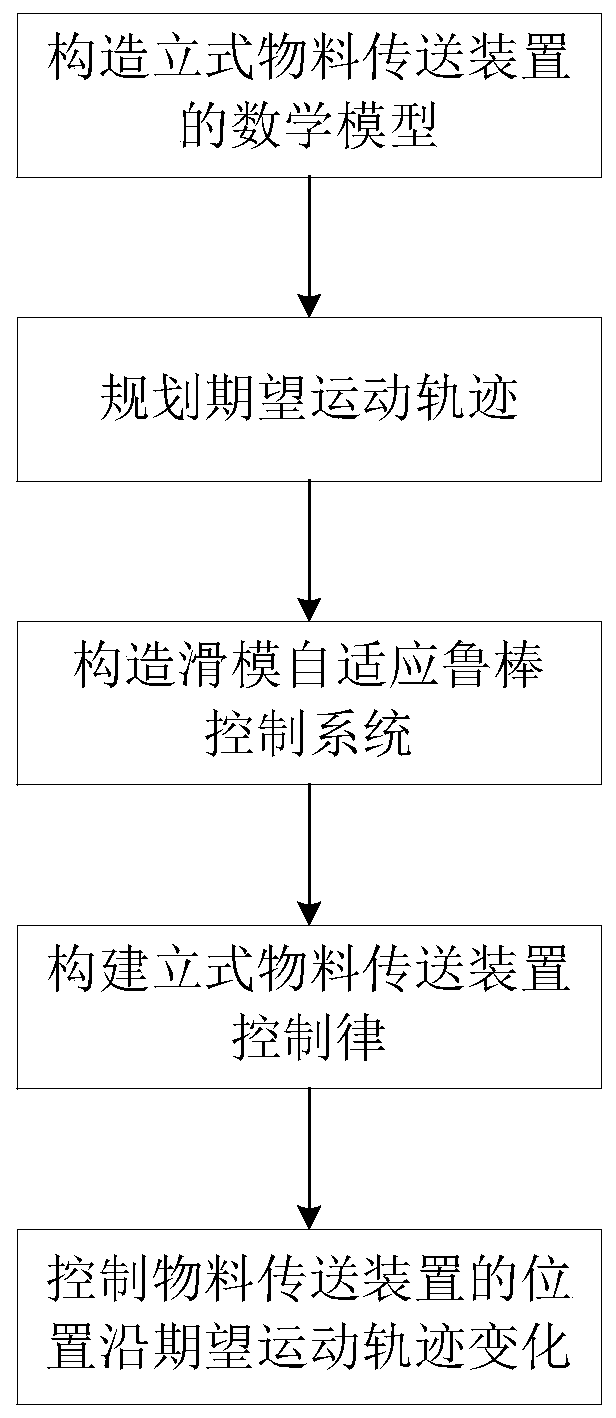

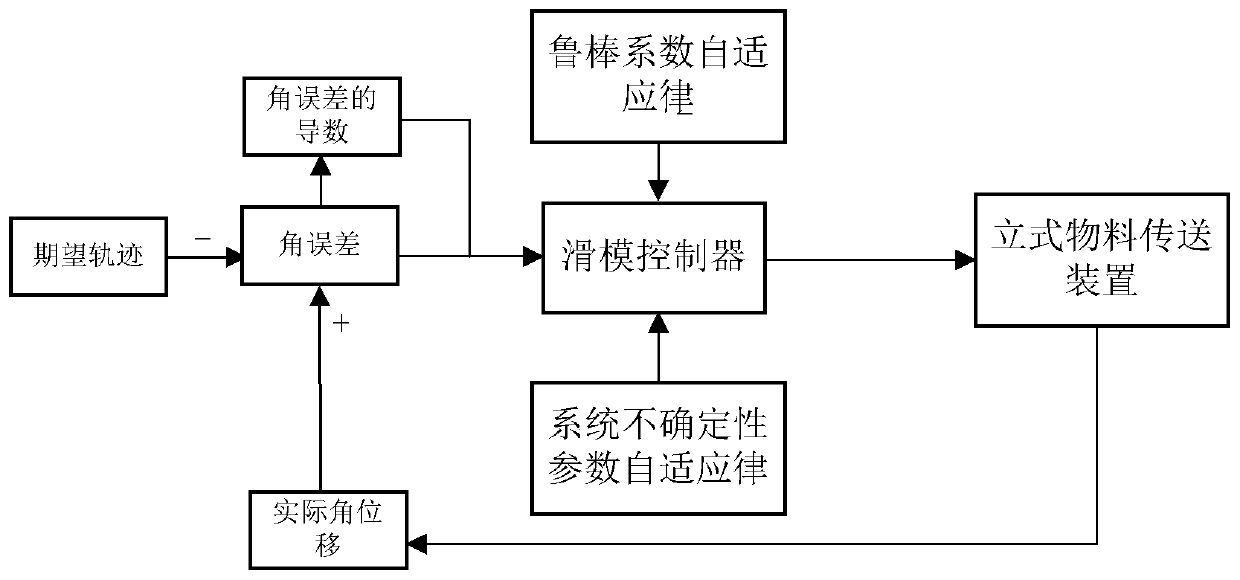

[0052] The position control method of the vertical material conveying device based on the sliding mode self-adaptive robust control of the present invention includes the following contents:

[0053] 1. The mathematical model of the vertical material conveying device is:

[0054]

[0055] In the formula, J is the unknown moment of inertia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com