Electromagnetic wave shield film, and shielded printed wiring board equipped with same

A technology for printed wiring boards and shielding films, applied in the fields of magnetic field/electric field shielding, crosstalk/noise/electromagnetic interference reduction (, printed circuits, etc.), which can solve problems such as the difficulty of thinning electromagnetic wave shielding films, and achieve excellent shielding properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0084]

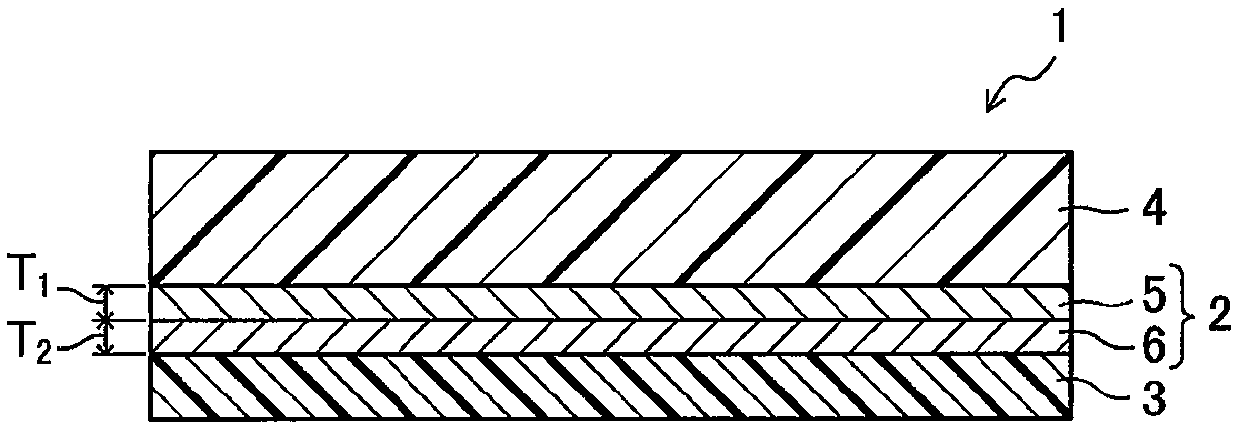

[0085] As a supporting base material, a PET film having a thickness of 60 μm and having a release treatment on the surface was used. Next, a composition for a protective layer (solid content: 30% by mass) composed of bisphenol novolac A-type epoxy resin (manufactured by Mitsubishi Chemical Co., Ltd., jER1256) and methyl ethyl ketone was applied on the supporting substrate, and By heating and drying, a support substrate with a protective layer having a thickness of 5 μm was produced.

[0086] Next, a shielding layer was formed on the surface of the protective layer. More specifically, a support substrate with a protective layer was installed in a batch vacuum evaporation apparatus (EBH−800 manufactured by ULVAC), and the vacuum arrival degree was adjusted to 5×10 in an argon atmosphere. −1 Below Pa, nickel was vapor-deposited to a thickness of 4.0 μm by a magnetron sputtering method (DC power supply output: 3.0 kW), and a first metal layer was formed.

[0087] Next...

Embodiment 2)

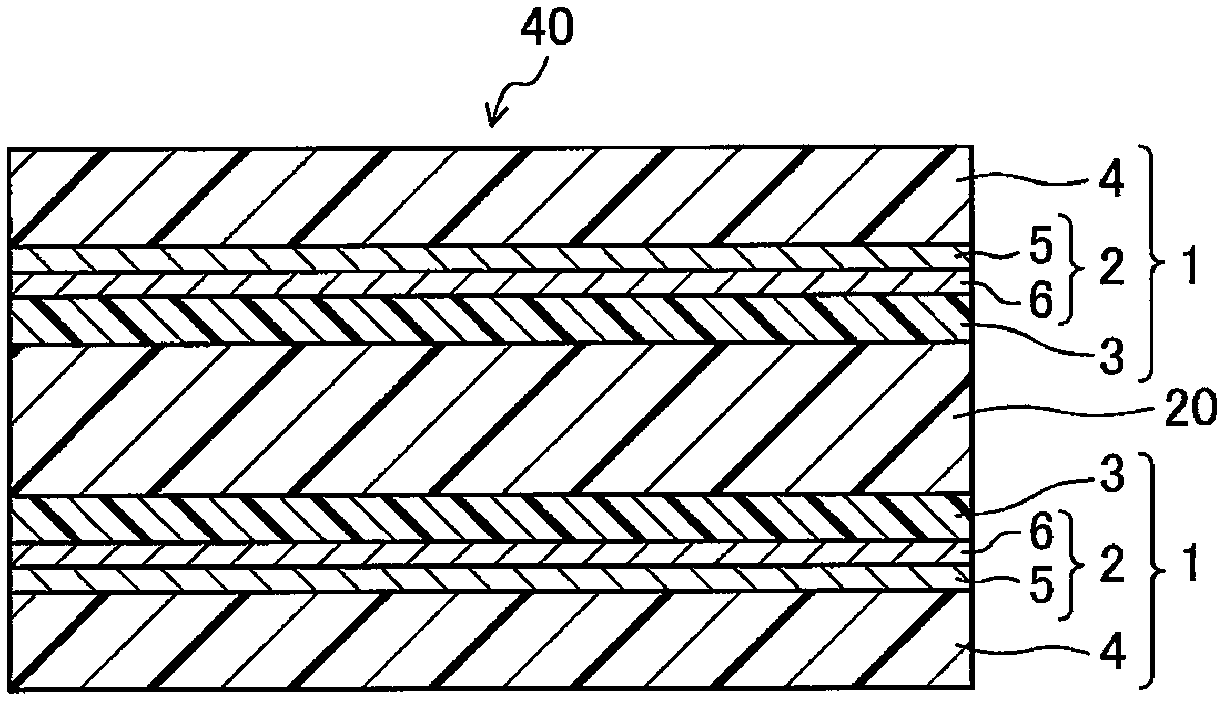

[0106] Except that the thickness of the first metal layer made of nickel was changed to 2 μm, an electromagnetic wave shielding film and a shielded printed wiring board were produced in the same manner as in Example 1, and the electric field wave and magnetic field wave shielding characteristics and output waveform characteristics were evaluated. Image 6 , Figure 7 , Figure 9 The above results are shown in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com