A kind of radiation protection gradient composite material and its preparation method and application

A composite material and anti-radiation technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, metal material coating technology, etc., can solve the problems of wide shielding range and small size, achieve good shielding characteristics, and efficiently shield radiation rays Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

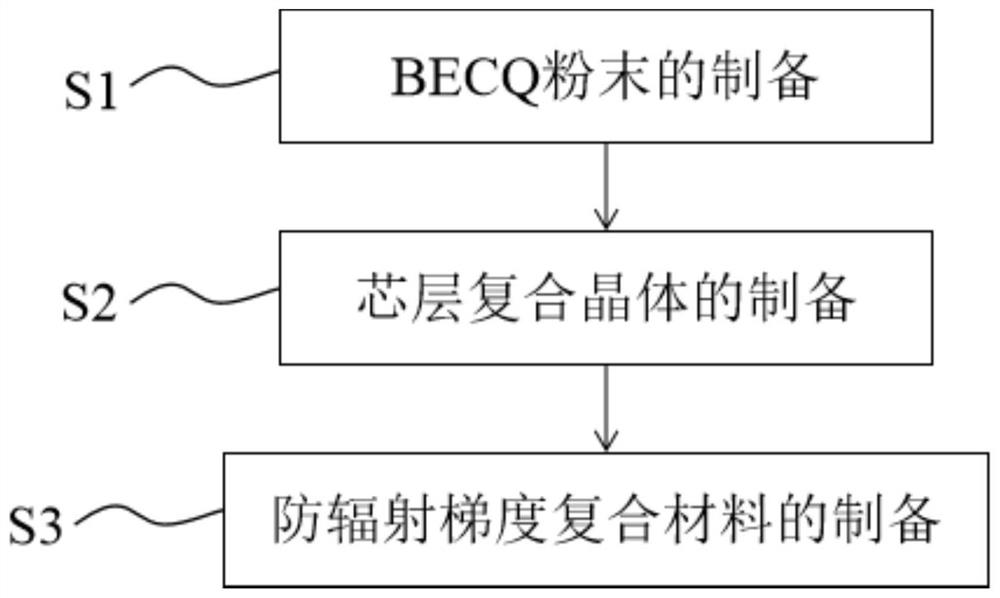

[0032] The preparation method of the radiation protection gradient composite material is as follows:

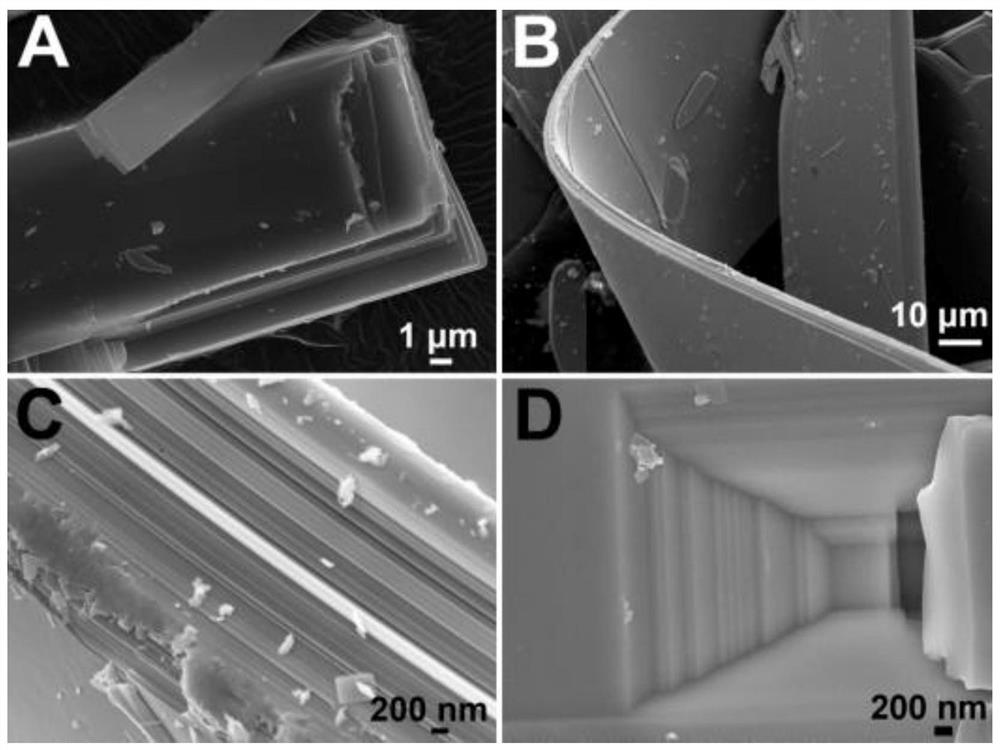

[0033]S1, BECQ powder preparation: in parts by weight, weigh 15 parts of ferric nitrate, 25 parts of silver nitrate, 20 parts of cerium acetate, and 2 parts of polyvinyl alcohol according to the proportion, and mix and obtain a hollow spherical shape through high temperature sintering, jet pulverization, and sieving. powder, then add 25 parts of samarium nitrate in proportion and use chemical vapor deposition method to coat the hollow spherical powder to make BECQ powder with a core-shell structure; the specific process of the chemical vapor deposition method is as follows: In the reaction vessel, the flow rate of hydrogen gas was 120ml / min, the flow rate of argon gas was 180ml / min, and the temperature of the reduction reaction was 900 ° C. After 70min of heat preservation reaction, finally obtained on the surface of the hollow spherical powder. Metal samarium coating;

[00...

Embodiment 2

[0037] The preparation method of the radiation protection gradient composite material is as follows:

[0038] S1, BECQ powder preparation: in parts by weight, weigh 23 parts of ferric sulfate, 23 parts of silver acetate, 28 parts of cerium nitrate, and 3 parts of polyvinyl alcohol according to the proportion, and mix them with high temperature sintering, jet milling, and sieving to obtain a hollow spherical shape. powder, then add 32 parts of samarium nitrate in proportion and use chemical vapor deposition method to coat the hollow spherical powder to make BECQ powder with a core-shell structure; the specific process of the chemical vapor deposition method is as follows: In the reaction vessel, the flow rate of hydrogen gas was 120ml / min, the flow rate of argon gas was 180ml / min, and the temperature of the reduction reaction was 950°C. Metal samarium coating;

[0039] S2, the preparation of the core layer composite crystal: the carbon powder is placed in the molybdenum wire r...

Embodiment 3

[0044] The preparation method of the radiation protection gradient composite material is as follows:

[0045] S1, preparation of BECQ powder: in parts by weight, weigh 30 parts of ferric nitrate, 35 parts of silver acetate, 35 parts of cerium acetate, and 5 parts of polyvinyl alcohol according to the proportion, and mix them with high temperature sintering, jet pulverization, and sieving to obtain a hollow spherical shape. powder, then add 40 parts of samarium nitrate in proportion and use chemical vapor deposition to coat the hollow spherical powder to make BECQ powder with a core-shell structure; the specific process of the chemical vapor deposition method is as follows: The flow rate of hydrogen gas introduced into the reaction vessel is 120ml / min, the flow rate of argon gas introduced is 180ml / min, and the temperature of the reduction reaction is 1000 ° C. After 70min of heat preservation reaction, finally obtained on the surface of the hollow spherical powder Metal samari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com