Coal seam step-by-step water injection precise control system and water injection method

A control system and technology for coal seams, which are used in earth-moving drilling, safety devices, surface mining, etc., can solve the problems of real-time monitoring and control of step-by-step water injection pressure and flow, and achieve increased wetting effect of water injection, improvement of physical properties, The effect of expanding the sphere of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

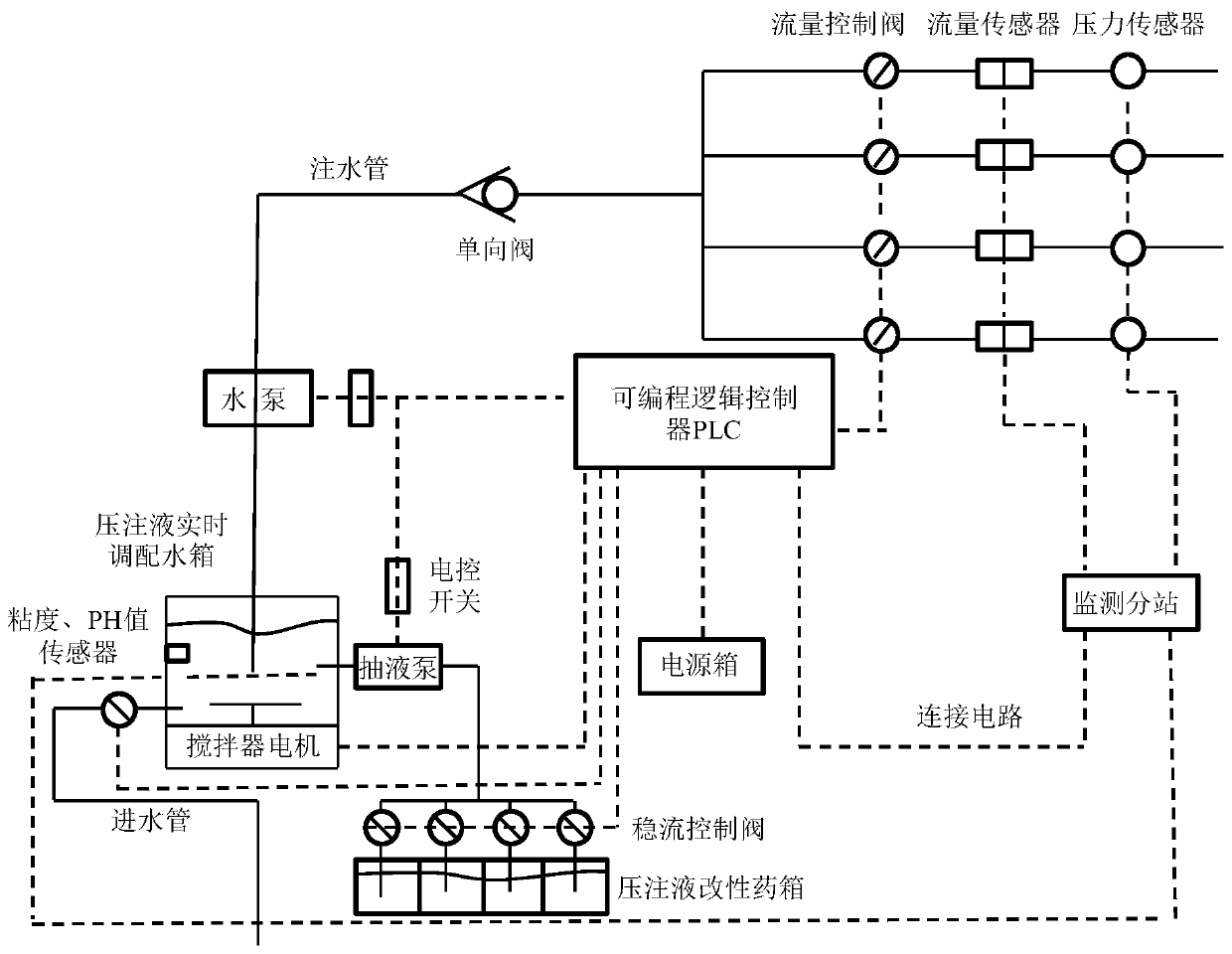

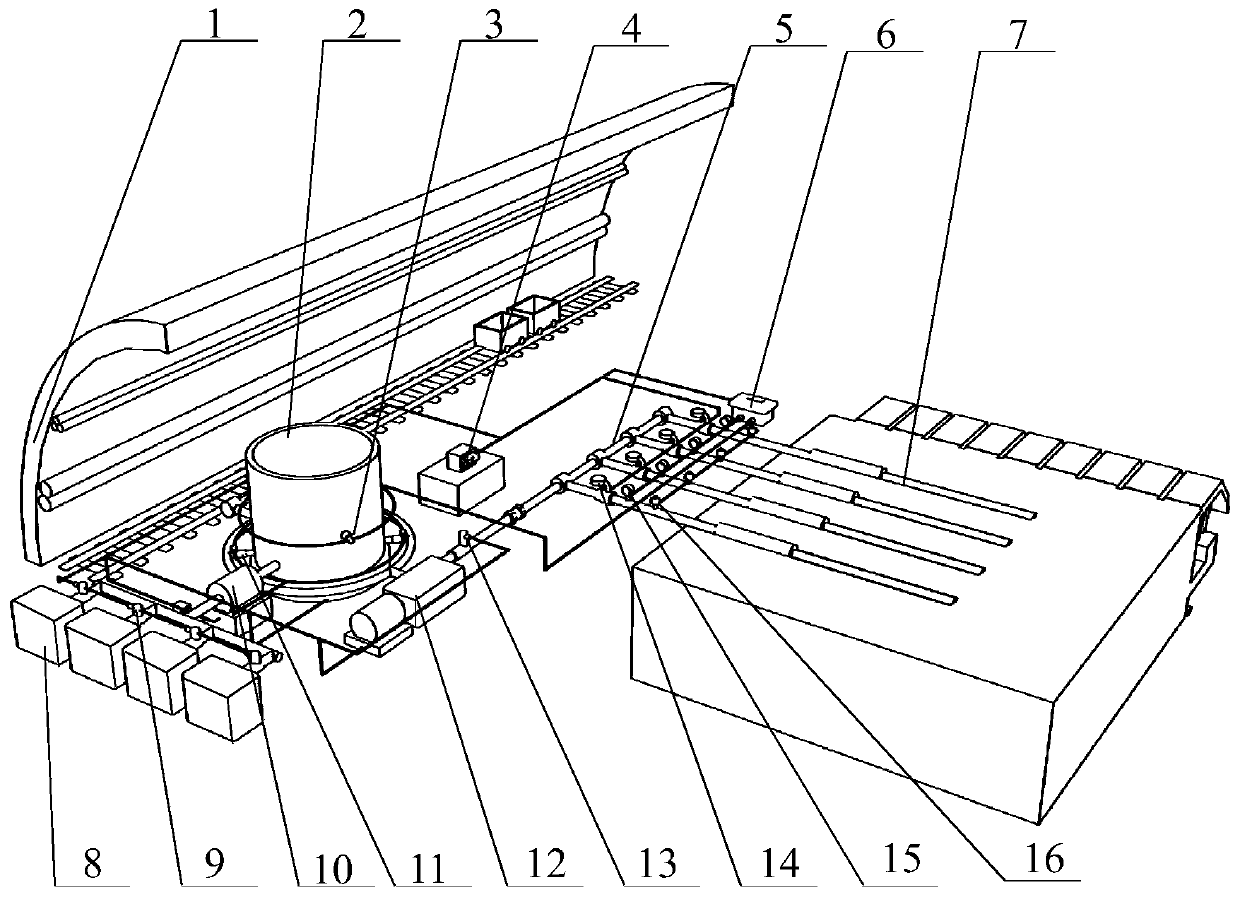

[0025] A step-by-step water injection precision control system for coal seams. The system includes a PLC controller, a data monitoring module, a water injection control module and a pressure injection control module. The PLC controller receives the monitoring data from the data monitoring module, and the PLC controller controls the water injection control module. Work with pressure injection fluid control module. The system realizes real-time monitoring of the pressure, flow and properties of the injection liquid of the water injection hole and the water injection system through the data monitoring module, and quantifies it through the PLC controller and programming language; controls the water injection through the PLC controller The control module completes the autonomous start and stop of the high-pressure water pump, changes the water injection flow, precisely regulates the required pressure in each process, and expands the scope of water injection; in addition, the PLC cont...

Embodiment 2

[0039] On the basis of Example 1, combined with the application of a coal seam step-by-step water injection precision control system in a certain mine, the beneficial effects of the coal seam step-by-step water injection method and the coal seam step-by-step water injection precision control system are further explained in detail.

[0040] A coal seam step-by-step water injection method in a mine uses the above-mentioned coal seam step-by-step water injection precision control system. The steps of water injection include:

[0041] Step 1. After the step-by-step precision control system for coal seam water injection is arranged in the roadway, water injection is started.

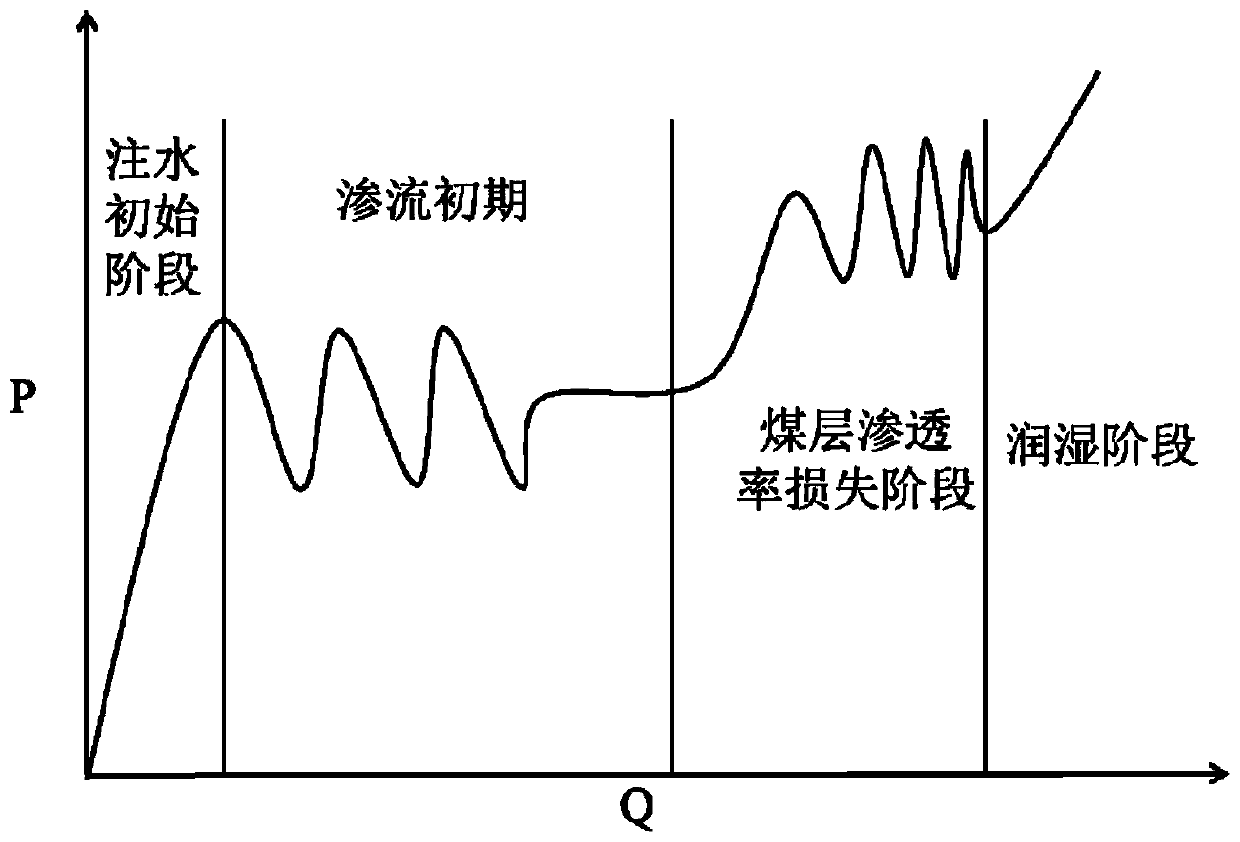

[0042] In the initial stage of water injection, the pressure sensor in the water injection hole and the flow sensor detect that the pressure P-the water injection flow Q curve continues to rise. Due to the holding pressure in the water injection hole, the PLC controller receives the monitoring data from the monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com