Burner meeting requirement of efficient regeneration in low-temperature condition of diesel particulate filter (DPF)

A particle trap and high-efficiency regeneration technology, which is applied in the direction of machines/engines, noise reduction devices, engine components, etc., can solve problems such as poor thermal effect and insufficient combustion, and achieve good thermal effect, avoid ignition failure, and complete combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

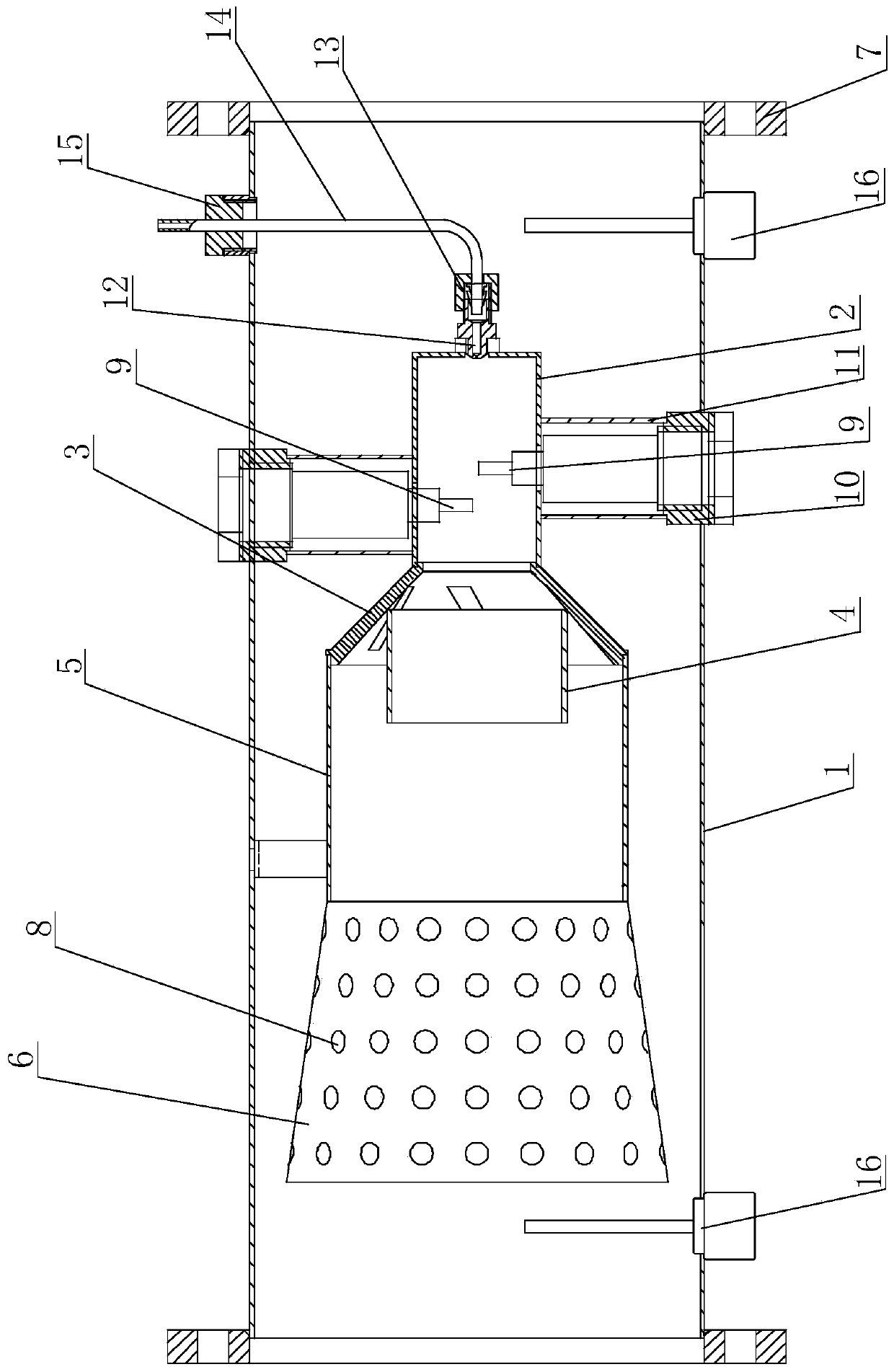

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] see figure 1 as shown, figure 1 It is a schematic structural diagram of a burner that satisfies the high-efficiency regeneration of the particle filter DPF under low temperature conditions provided by the specific embodiment of the present invention.

[0024] In this embodiment, a combustor that satisfies the high-efficiency regeneration of the particle filter DPF under low temperature conditions includes an outer casing 1 and a combustion chamber 2 arranged in the outer casing 1, an intake diversion mixer 3, an inner combustion jacket 4, The first-stage outer combustion jacket 5 and the second-stage outer combustion jacket 6, both ends of the outer casing 1 are welded and fixed with connecting flanges 7, and the outer casing 1 is fixedly connected to the exhaust pipe of the diesel engine th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com