Contact flue gas heat exchange device for flue

A flue gas heat exchange, contact technology, applied in the direction of direct contact heat exchangers, heat exchanger types, lighting and heating equipment, etc., to achieve the effect of reducing flow resistance, small resistance, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

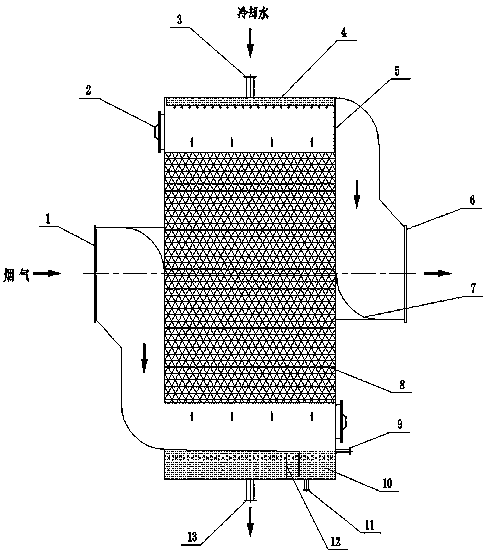

[0015] The invention provides a flue gas heat exchange device for flue contact, the device includes a flue gas inlet (1), an inspection port (2), a cooling water inlet (3), a water distributor (4), a defogger Device (5), flue gas outlet (6), deflector (7), packing (8), overflow (9), sump (10), sewage outlet (11), antifouling baffle (12 ), cooling water outlet (13) and other components.

[0016] It is characterized in that: the flue gas of coal-fired boiler or gas-fired boiler enters the device through the flue gas inlet (1), and the flue gas enters the bottom flue smoothly through the action of the deflector (7), and then is mixed with the packing (8) The liquid film water conducts sufficient and uniform contact heat exchange, and finally, the flue gas is discharged from the flue gas outlet (6) through the demisting device (5). The circulating cooling water enters the water distributor (4) from the cooling water inlet (3), passes through the filler (8) uniformly and dispersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com