Air bridge integrated inductor and manufacturing method thereof

A technology integrating inductors and manufacturing methods, which is applied in the direction of inductors, circuits, electrical components, etc., and can solve problems such as the decrease of the Q value of the inductor, the reduction of the magnetic flux of the inductor coil, and the large energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0043] see Figure 1 to Figure 11 , This embodiment provides a method for preparing an air bridge integrated inductor, which is used on a wafer, which can reduce the occupation of the surface area of the wafer, improve the integration degree of the chip, and reduce the production cost of the chip.

[0044] The present invention comprises the steps:

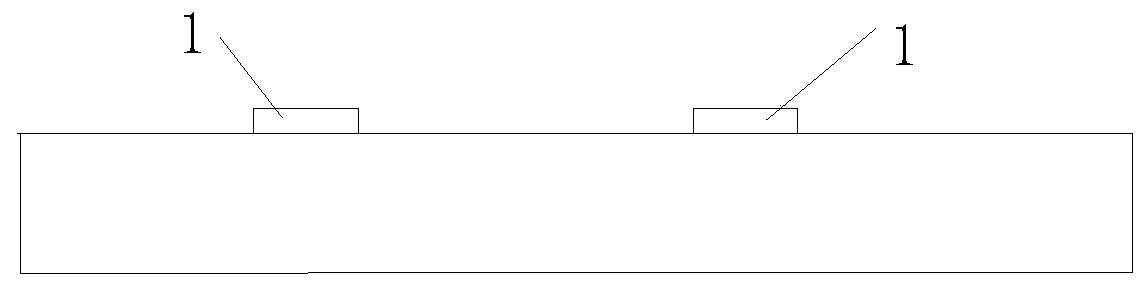

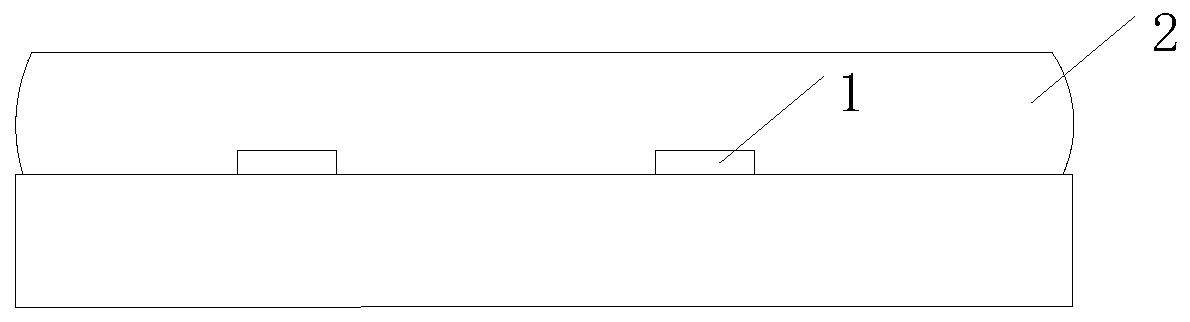

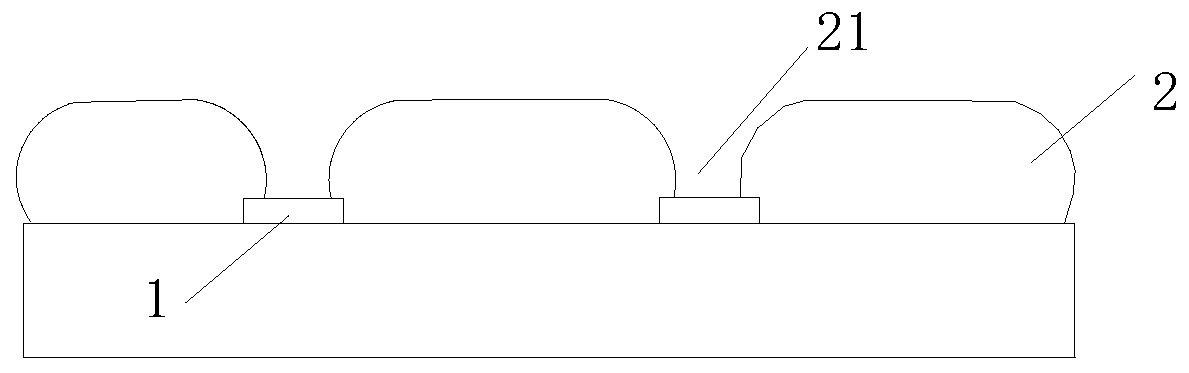

[0045] Fabricating the first inductive metal layer 1 by evaporation on the substrate; Figure 11 Among them, AE, BF, CG, DH, I, and J are all the first inductive metal layers; among them, AE, BF, CG, and DH are parallel laminate structures.

[0046] Fabricate the first layer of photoresist 2 on the first inductive metal layer 1, etch the pier position of the air bridge to be made to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com