Full-automatic numerical control grinding machine

A CNC grinding machine, fully automatic technology, applied in the direction of grinding machines, grinding bed, grinding machine parts, etc., can solve the problems of precision drop, finished workpiece defects, troubles, etc., to achieve improved accuracy, wide grinding range, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

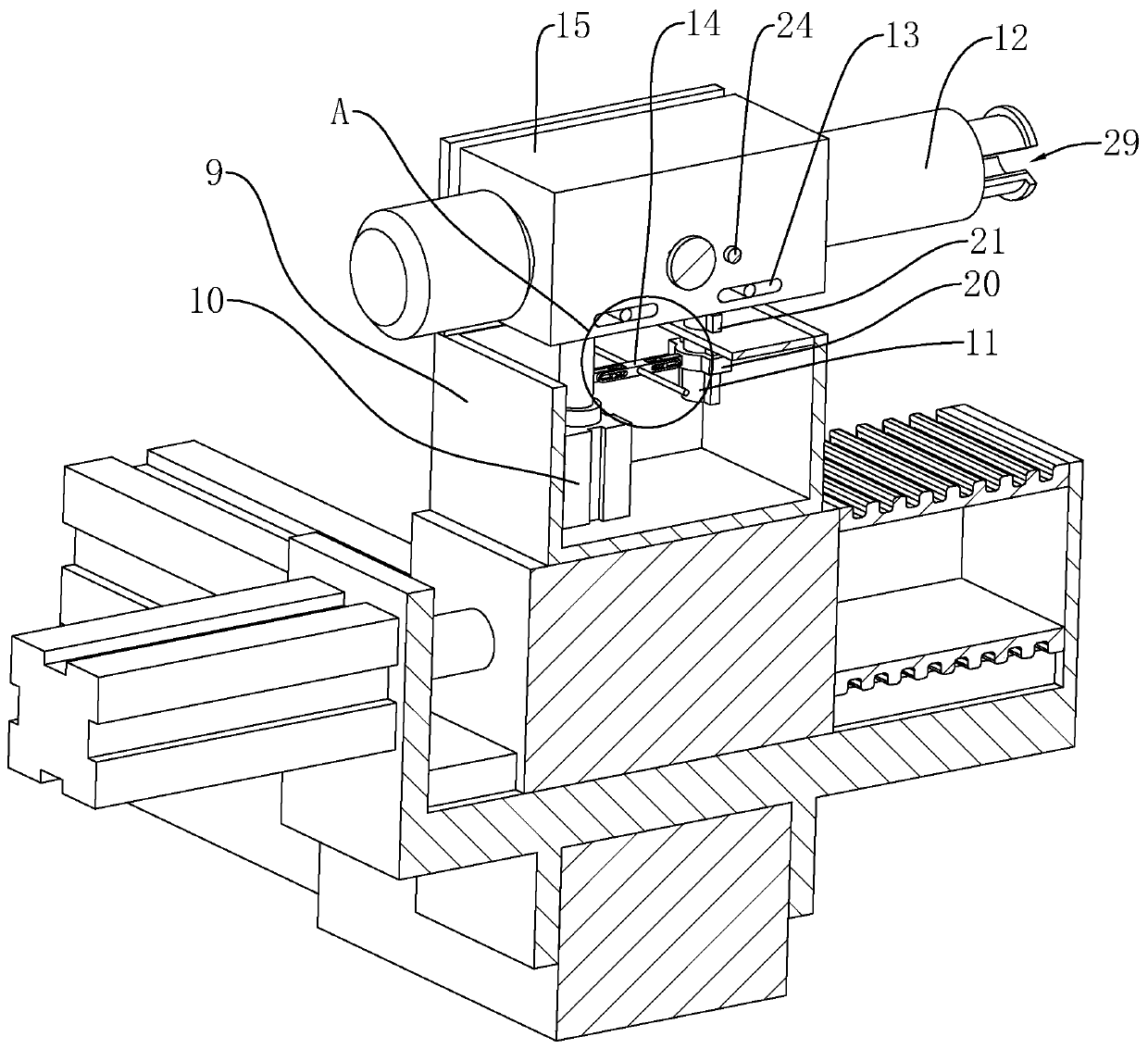

[0033] The present invention will be further described with reference to the accompanying drawings.

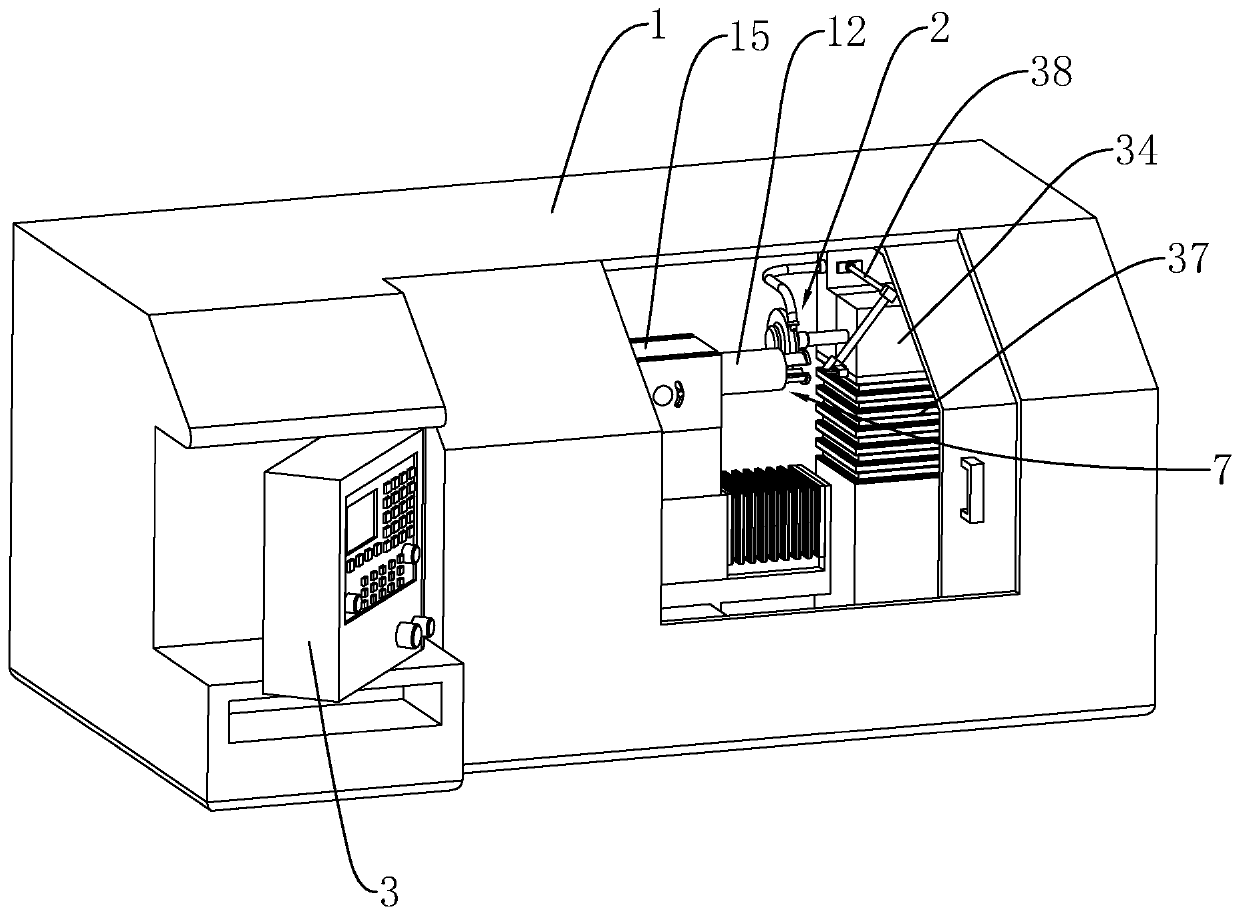

[0034] Such as figure 1 As shown, a fully automatic numerical control grinding machine includes an operation room 1, and a control panel 3 for controlling the operation of the internal components of the operation room 1 is installed on the outside of the operation room 1.

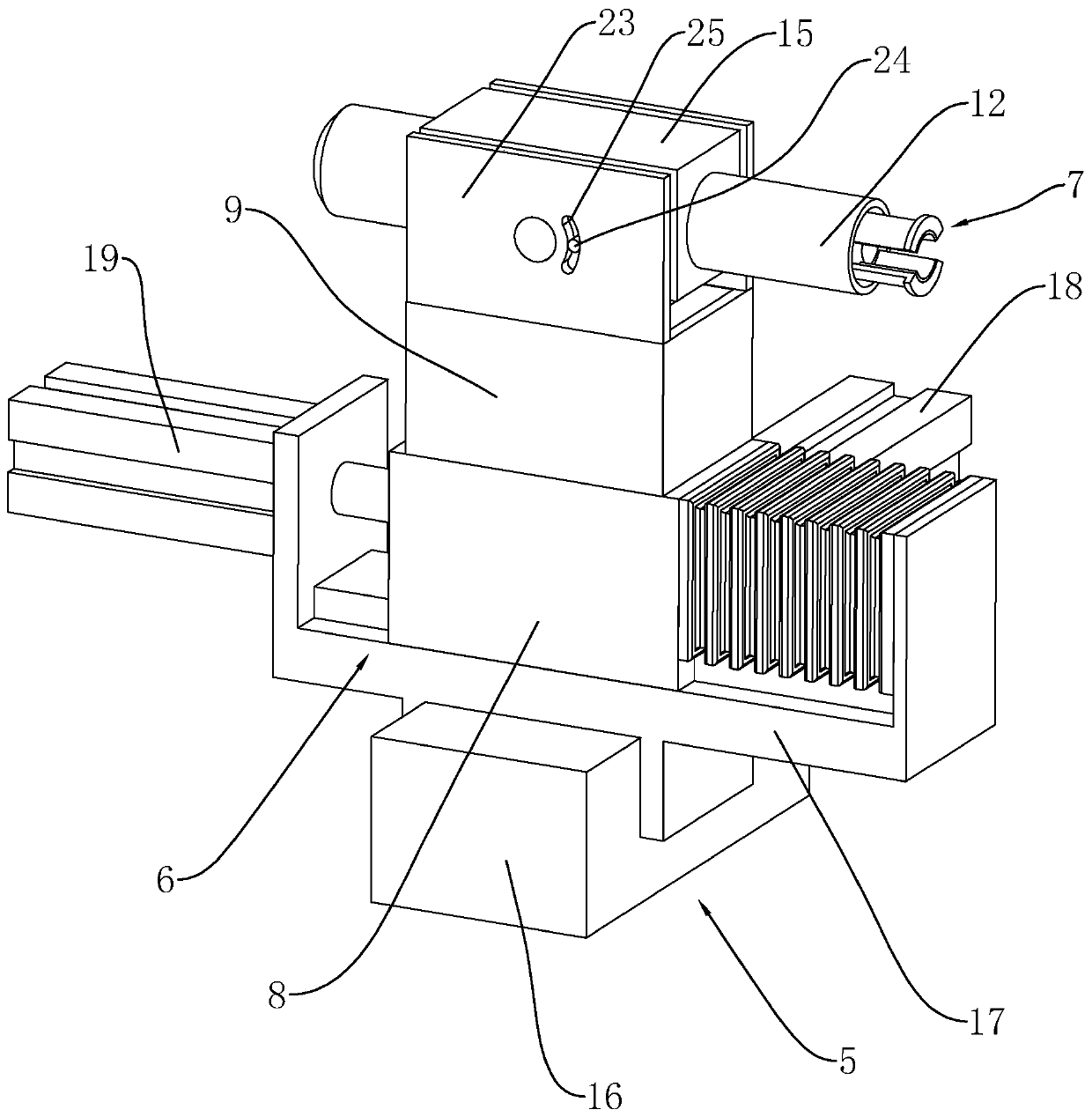

[0035] Such as figure 1 , figure 2 As shown, the first traveling mechanism 5 sliding along the Y-axis is installed in the operating room 1. The first traveling mechanism 5 includes a guide rail 16 fixed in the operating room 1 along the Y-axis direction, and a slide plate slid on the guiding rail 16. 17. The sliding plate 17 is slidably arranged on the guide rail 16 along the Y-axis direction, both ends of the sliding plate 17 are beyond the sidewall of the guide rail 16, and the sliding plate 17 is placed along the X-axis direction. The upper end of the guide rail 16 is equipped with a second cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com