Preparation method of anti-aging BOPP film

An anti-aging and anti-aging technology, applied in the field of new materials, can solve the problems of general anti-aging performance, shortened life, and reduced mechanical properties of biaxial polypropylene films, achieve excellent thermal-oxidative aging performance, improve service life, The effect of reduced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

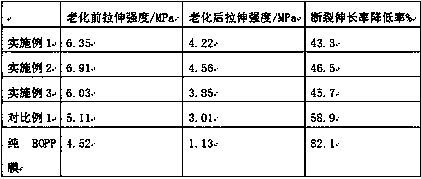

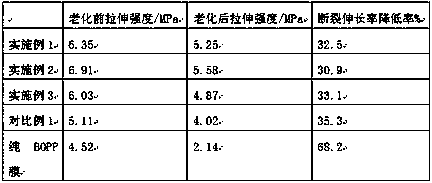

Examples

Embodiment 1

[0020] A method for preparing an aging-resistant BOPP film, comprising the following steps:

[0021] (1) Nano-filler preparation: uniformly disperse nano-graphene into an ethanol solution with a mass fraction of 20%, then add o-ethoxyphenol with a mass of 3.5% nano-graphene to the ethanol solution, and keep stirring at 70°C for 2 hour, then add potassium permanganate of 0.1% of the nano-graphene quality, adjust the ethanol solution to acidity, continue to insulate and stir for 2 hours, then carry out suction filtration, wash to neutral, and dry to constant weight to obtain the modified nano-filler ;

[0022] (2) Preparation of anti-aging modifier: Add 12-hydroxystearic acid into the reaction kettle, heat to 130°C, stir for 15 minutes, then add diethanolamine and lignin, dehydrate under reduced pressure for 20 minutes, and then lower the temperature to 70°C, add a catalyst, continue to stir and react for 3 hours, and obtain the reaction product, which is purified to obtain the...

Embodiment 2

[0033] A method for preparing an aging-resistant BOPP film, comprising the following steps:

[0034] (1) Nano-filler preparation: uniformly disperse nano-graphene into an ethanol solution with a mass fraction of 25%, then add o-ethoxyphenol with a mass of 3.5-4% nano-graphene to the ethanol solution, and keep warm at 75°C Stir for 2 hours, then add potassium permanganate with 0.1% nano-graphene quality, adjust the ethanol solution to acidity, continue to heat and stir for 2 hours, then carry out suction filtration, wash to neutral, dry to constant weight, and obtain modified nanofillers;

[0035] (2) Preparation of anti-aging modifier: Add 12-hydroxystearic acid into the reaction kettle, heat to 140°C, stir for 20 minutes, then add diethanolamine and lignin, dehydrate under reduced pressure for 25 minutes, and then lower the temperature to 70°C, add a catalyst, continue to stir and react for 3 hours, and obtain the reaction product, which is purified to obtain the product;

...

Embodiment 3

[0046] A method for preparing an aging-resistant BOPP film, comprising the following steps:

[0047] (1) Nano-filler preparation: uniformly disperse nano-graphene into an ethanol solution with a mass fraction of 22%, then add o-ethoxyphenol with a mass of 3.5-4% nano-graphene to the ethanol solution, and keep warm at 73°C Stir for 2 hours, then add potassium permanganate with 0.1% nano-graphene quality, adjust the ethanol solution to acidity, continue to heat and stir for 2 hours, then carry out suction filtration, wash to neutral, dry to constant weight, and obtain modified nanofillers;

[0048] (2) Preparation of anti-aging modifier: Add 12-hydroxystearic acid into the reaction kettle, heat to 135°C, stir for 18 minutes, then add diethanolamine and lignin, dehydrate under reduced pressure for 22 minutes, and then lower the temperature to 70°C, add a catalyst, continue to stir and react for 3 hours, and obtain the reaction product, which is purified to obtain the product;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com