Preparation method of pigment red 146

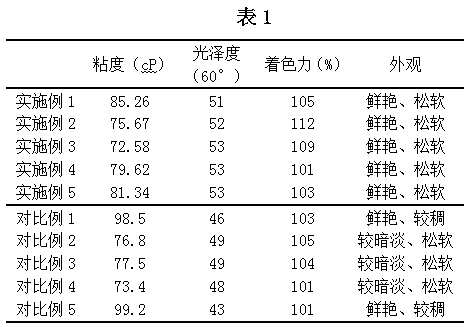

A pigment red and red-based technology, used in the preparation of pigment red 146, can solve the problems that pigment red cannot achieve bright luster, poor dispersion stability, and high viscosity of pigment red, and achieve excellent solubilization and dispersion effect, strong tinting strength, light high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of Pigment Red 146, comprising the following steps:

[0048](1) Mix 100kg of deionized water, 7kg of Red Base No. 1, 10kg of 25% hydrochloric acid and 8kg of glacial acetic acid, stir for 15 minutes until dissolved, then cool down to 4°C, add 25% sodium nitrite solution, and react 30min to obtain coupling solution a;

[0049] (2) Dissolve 3kg of sodium hydroxide in 200kg of deionized water, add surfactant No. 1, heat up to 80°C, add naphthol AS-LC to dissolve, and obtain coupling solution b;

[0050] (3) At 35°C, drop the coupling solution b into the coupling solution a for mixing. After reacting for 60 minutes, keep it warm at 80°C for 30 minutes, filter with suction, wash with water until neutral, and dry at 75°C to obtain the finished product.

Embodiment 2

[0052] A preparation method of Pigment Red 146, comprising the following steps:

[0053] (1) Mix 100kg of deionized water, 8kg of Red Base II, 15kg of 30% hydrochloric acid and 10kg of glacial acetic acid, stir for 15 minutes until dissolved, then cool down to 3°C, add 35% sodium nitrite solution, React for 35 minutes to obtain coupling solution a;

[0054] (2) Dissolve 5kg of sodium hydroxide in 200kg of deionized water, add surfactant No. 2, heat up to 95°C, add naphthol AS-LC to dissolve, and obtain coupling solution b;

[0055] (3) At 30°C, drop the coupling solution a into the coupling solution b for mixing, react for 70 minutes and then keep warm at 95°C for 30 minutes, filter with suction, wash with water until neutral, and dry at 85°C to obtain the finished product.

Embodiment 3

[0057] A preparation method of Pigment Red 146, comprising the following steps:

[0058] (1) Mix 100kg of deionized water, 7.5kg of Red Base No. 3, 12kg of 28% hydrochloric acid and 9kg of glacial acetic acid, stir for 10 minutes until dissolved, then cool down to 4°C, and add 30% sodium nitrite solution , reacted for 32 minutes to obtain coupling solution a;

[0059] (2) Dissolve 4kg of sodium hydroxide in 200kg of deionized water, add surfactant No. 3, heat up to 90°C, add naphthol AS-LC to dissolve, and obtain coupling solution b;

[0060] (3) At 25°C, slowly drop the coupling solution a into the coupling solution b for mixing, react for 65 minutes, then keep it warm at 85°C for 30 minutes, filter with suction, wash with water until neutral, and dry at 80°C to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com