A water-based temperature-controlled adhesive-release adhesive emulsion, a water-based temperature-controlled adhesive-release adhesive obtained therefrom, and a preparation method thereof

A technology of latex and adhesive release glue, which is applied in the direction of acidic copolymer adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems that cannot meet the use requirements, and achieve easy large-scale production, particle size, etc. The effect of small diameter and high product processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

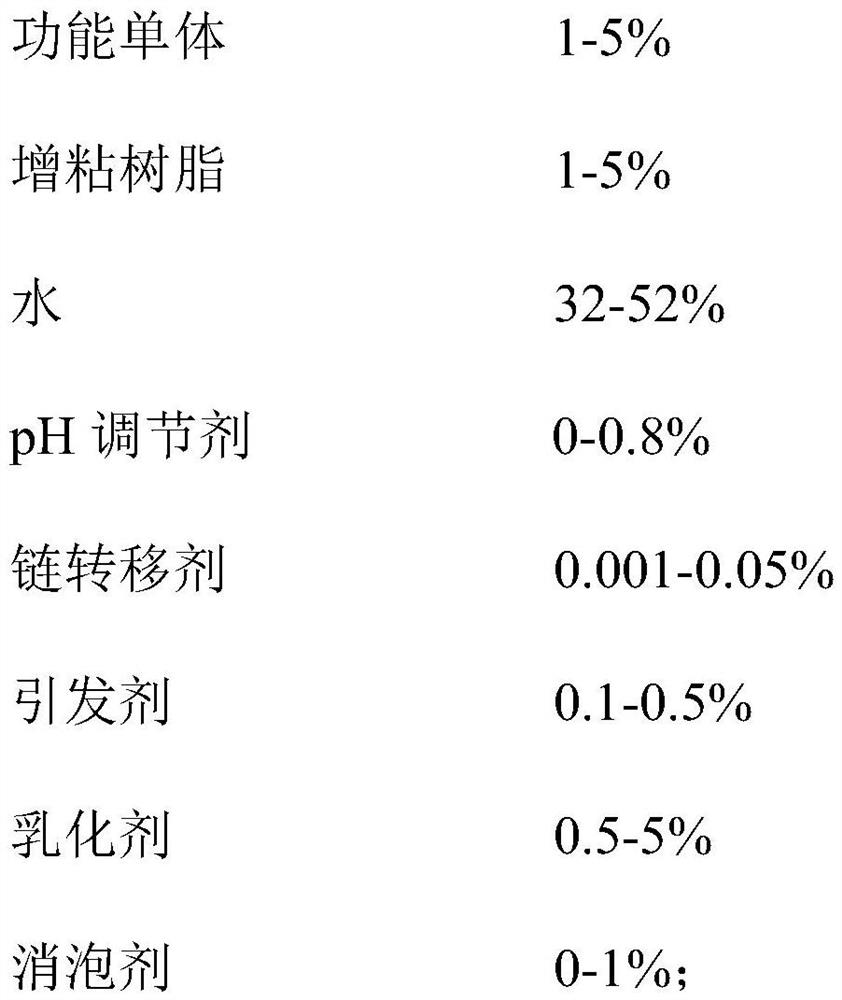

Method used

Image

Examples

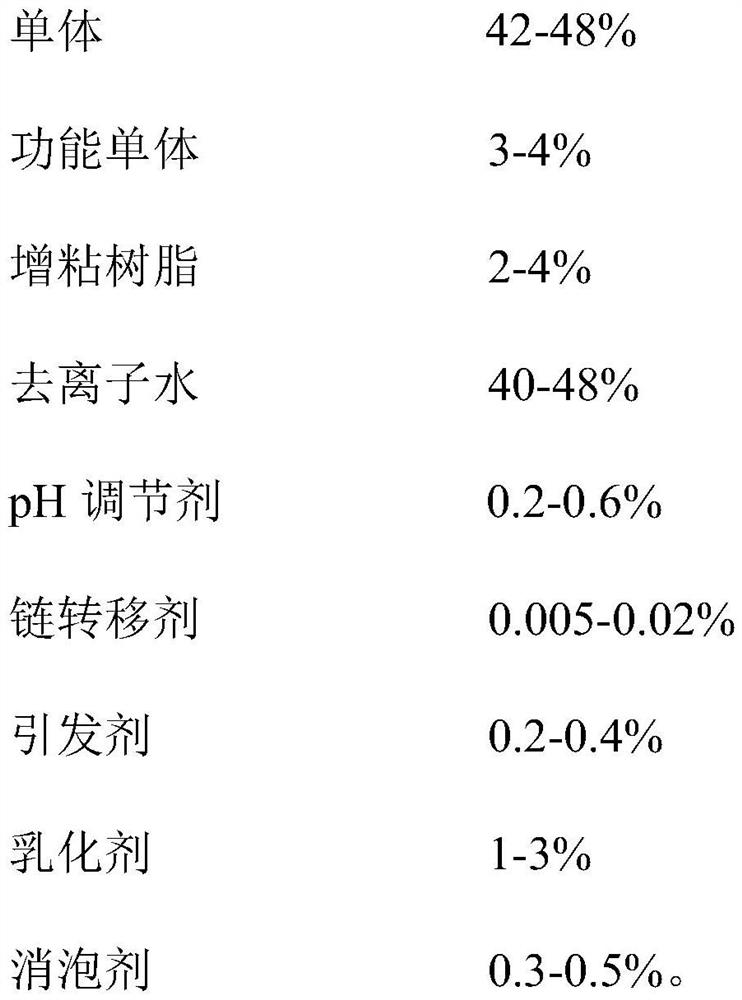

Embodiment 1

[0062] The preparation of water-based temperature-controlled adhesive-release adhesive comprises the following steps:

[0063] Step 1: Weigh each raw material according to the mass percentage in Table 1, add the emulsifier to 60-80wt% (relative to all water addition) water, stir at a speed of 200r / min, stir for 15min, and mix well; heat up to 45°C , add tackifying resin, stir at 400r / min, disperse for 40min; cool down to room temperature, add a pH regulator to adjust the pH to 6, stir evenly, and obtain A liquid;

[0064] Step 2: In a protective atmosphere, add macromonomer, functional monomer and chain transfer agent to the liquid A obtained in the previous step, stir at a speed of 200r / min, and react at a temperature of 65°C for 1.5h to obtain liquid B;

[0065] Step 3: raise the temperature of liquid B to 75°C; keep the temperature at 75°C, add the initiator dropwise to liquid B, and dissolve the initiator with 10-30wt% (relative to all water addition) water in advance, and...

Embodiment 2

[0072] For the preparation of water-based temperature-controlled adhesive, the dosage of each substance is shown in Table 1, and the preparation method is the same as that of Example 1.

Embodiment 3

[0074] For the preparation of water-based temperature-controlled adhesive, the dosage of each substance is shown in Table 1, and the preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com