Oxygen-enriched combustion method for iron and steel system

An oxygen-enriched combustion, steel technology, applied in blast furnace parts, heating furnaces, blast furnaces, etc., can solve problems such as the inability to achieve oxygen-enriched combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

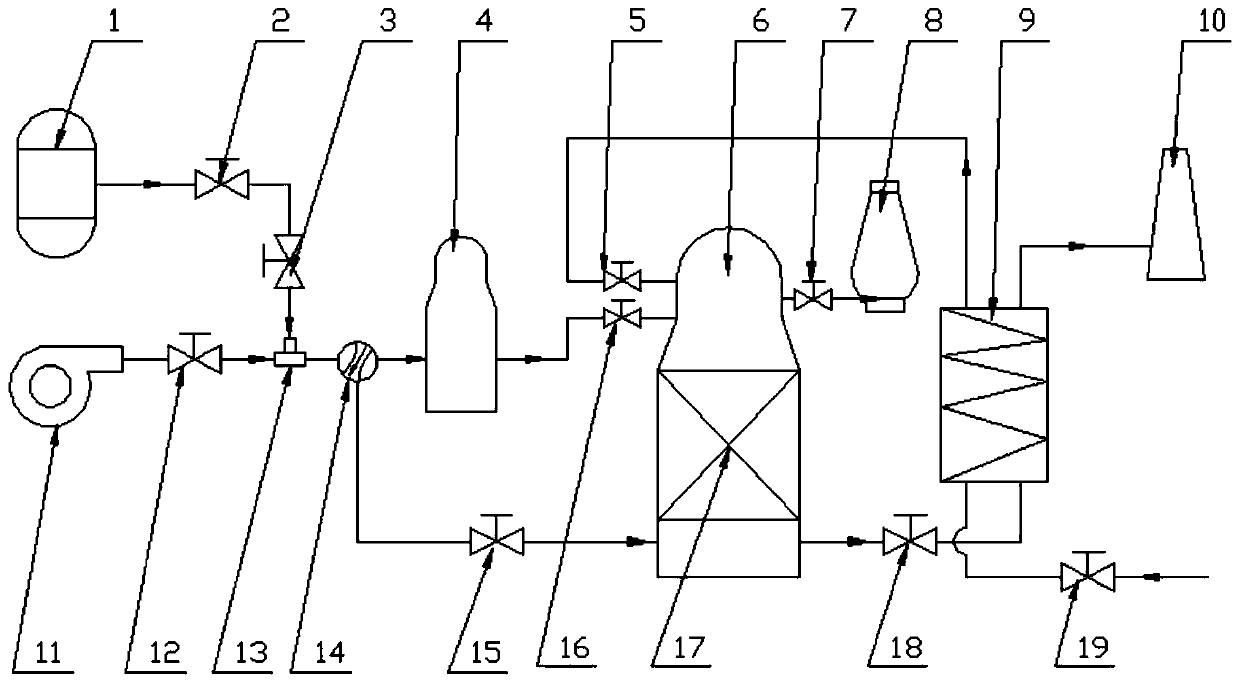

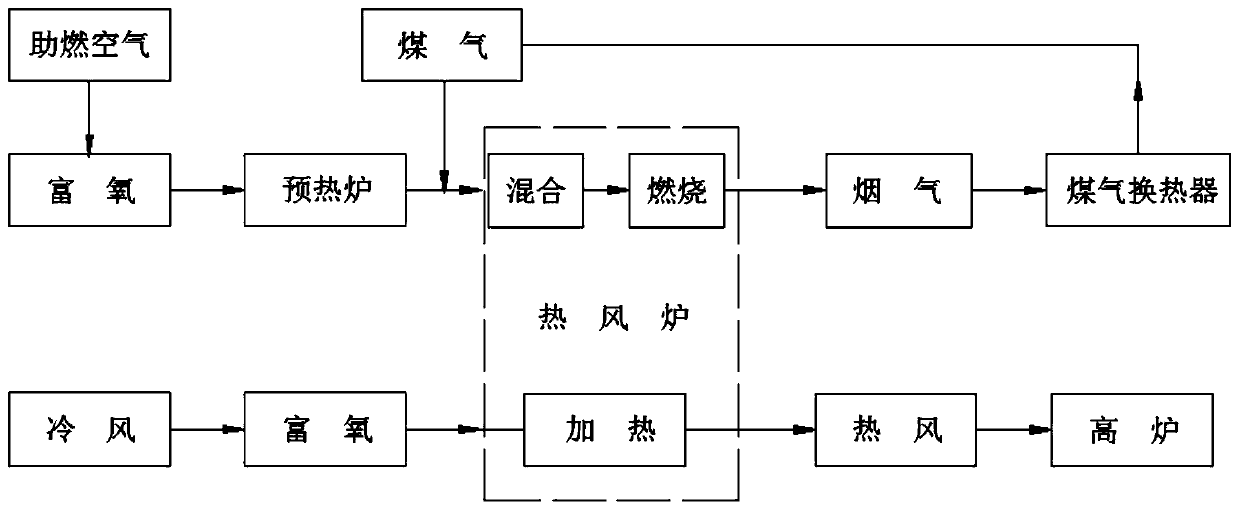

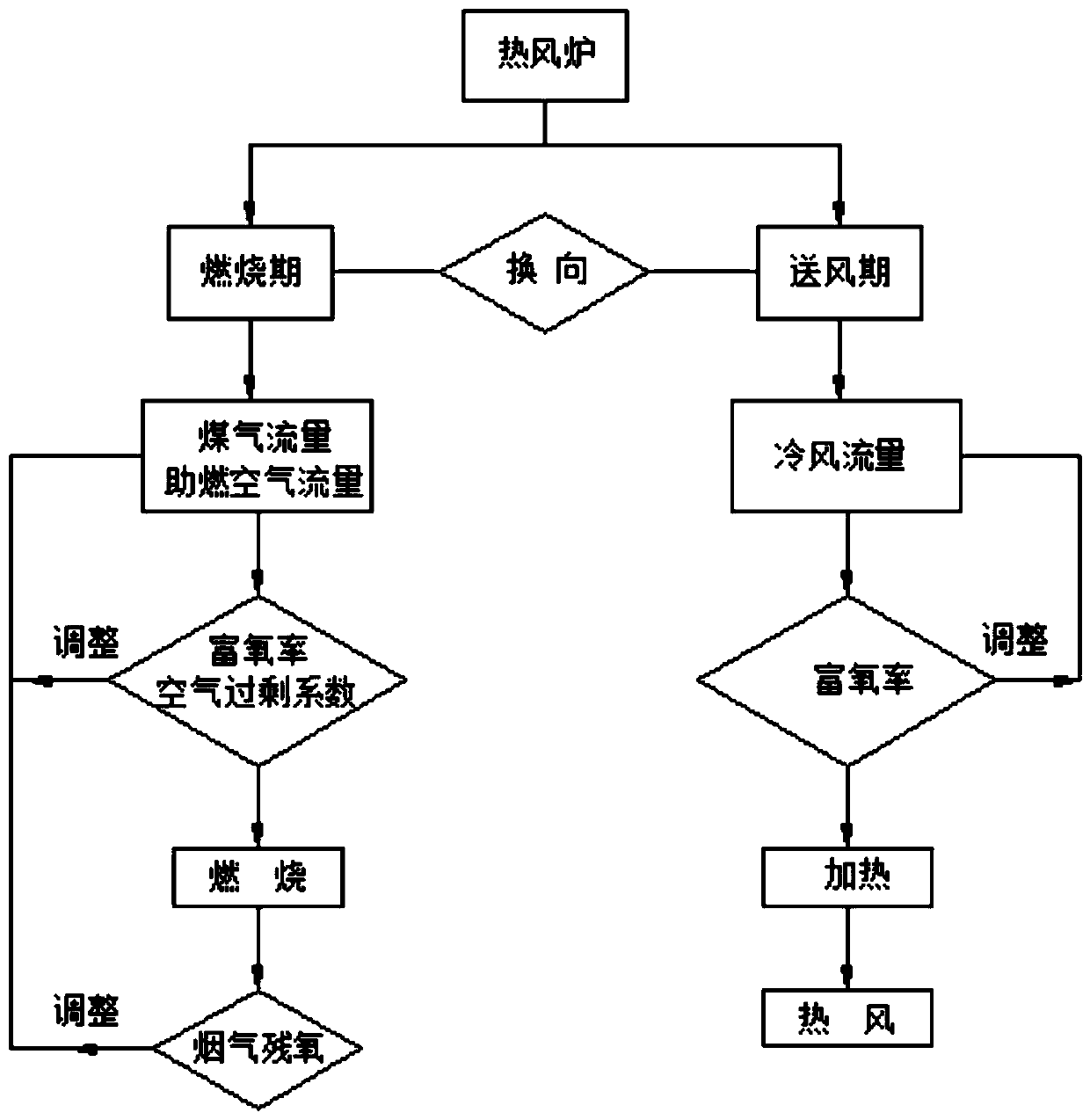

[0070] During the combustion period of the hot blast stove 6, the liquid oxygen from the high-pressure oxygen tank 1 is decompressed by the pressure regulating valve 2 and regulated by the oxygen flow regulating valve 3 to become gaseous oxygen with a pressure of 10, and the gaseous oxygen from the blower 11 is passed through the air volume regulating valve 12 After adjustment, the combustion-supporting air with a pressure of 10 is mixed into oxygen-enriched air, wherein the volume ratio of the oxygen flow rate to the combustion-supporting air flow rate is 2%, and the oxygen-enriched air passing through the three-way valve 13 and the reversing valve 14 is preheated by the preheating furnace 4. at 450°C, through the first hot blast valve 7 and the preheated blast furnace 8 coal gas through the gas heat exchanger 9, they enter the hot blast stove 6 together and are mixed and burned into flue gas with a temperature of 1340°C. The heat exchanger 9 preheats the gas temperature of th...

Embodiment 2

[0073] During the combustion period of the hot blast stove 6, the liquid oxygen from the high-pressure oxygen tank 1 is decompressed by the pressure regulating valve 2 and regulated by the oxygen flow regulating valve 3 to become gaseous oxygen with a pressure of 15kPa, and the gaseous oxygen from the blower 11 through the air volume regulating valve 12 After adjustment, the combustion-supporting air with a pressure of 15kPa is mixed into oxygen-enriched air, wherein the volume ratio of the oxygen flow rate to the combustion-supporting air flow rate is 5%, and the oxygen-enriched air passing through the three-way valve 13 and the reversing valve 14 is preheated by the preheating furnace 4. The temperature is 650°C, and the first hot blast valve 7 and the preheated blast furnace 8 coal gas through the gas heat exchanger 9 enter the hot blast stove 6 and mix and burn into flue gas with a temperature of 1440°C. The heat exchanger 9 preheats the gas temperature of the blast furnace...

Embodiment 3

[0076] During the combustion period of the hot blast stove 6, the liquid oxygen from the high-pressure oxygen tank 1 is decompressed by the pressure regulating valve 2 and regulated by the oxygen flow regulating valve 3 to become gaseous oxygen with a pressure of 13kPa, which is mixed with the gaseous oxygen from the blower 11 through the air volume regulating valve 12 After adjustment, the combustion-supporting air with a pressure of 13kPa is mixed into oxygen-enriched air, wherein the volume ratio of the oxygen flow rate to the combustion-supporting air flow rate is 3%, and the oxygen-enriched air passing through the three-way valve 13 and the reversing valve 14 is preheated by the preheating furnace 4. The temperature is 600°C, through the first hot blast valve 7 and the preheated blast furnace 8 coal gas through the gas heat exchanger 9 enters the hot blast stove 6 together and combusts into flue gas with a temperature of 1400°C, after heat exchange through the checker brick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com