Mixed knitting loom

A loom and mixed weaving technology, which is applied in looms, textiles, mechanical cleaning, etc., can solve problems such as inconvenient use, inability to clean up rough edges and waste, and affect sales, so as to ensure stability, reduce difficulty, and be convenient to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

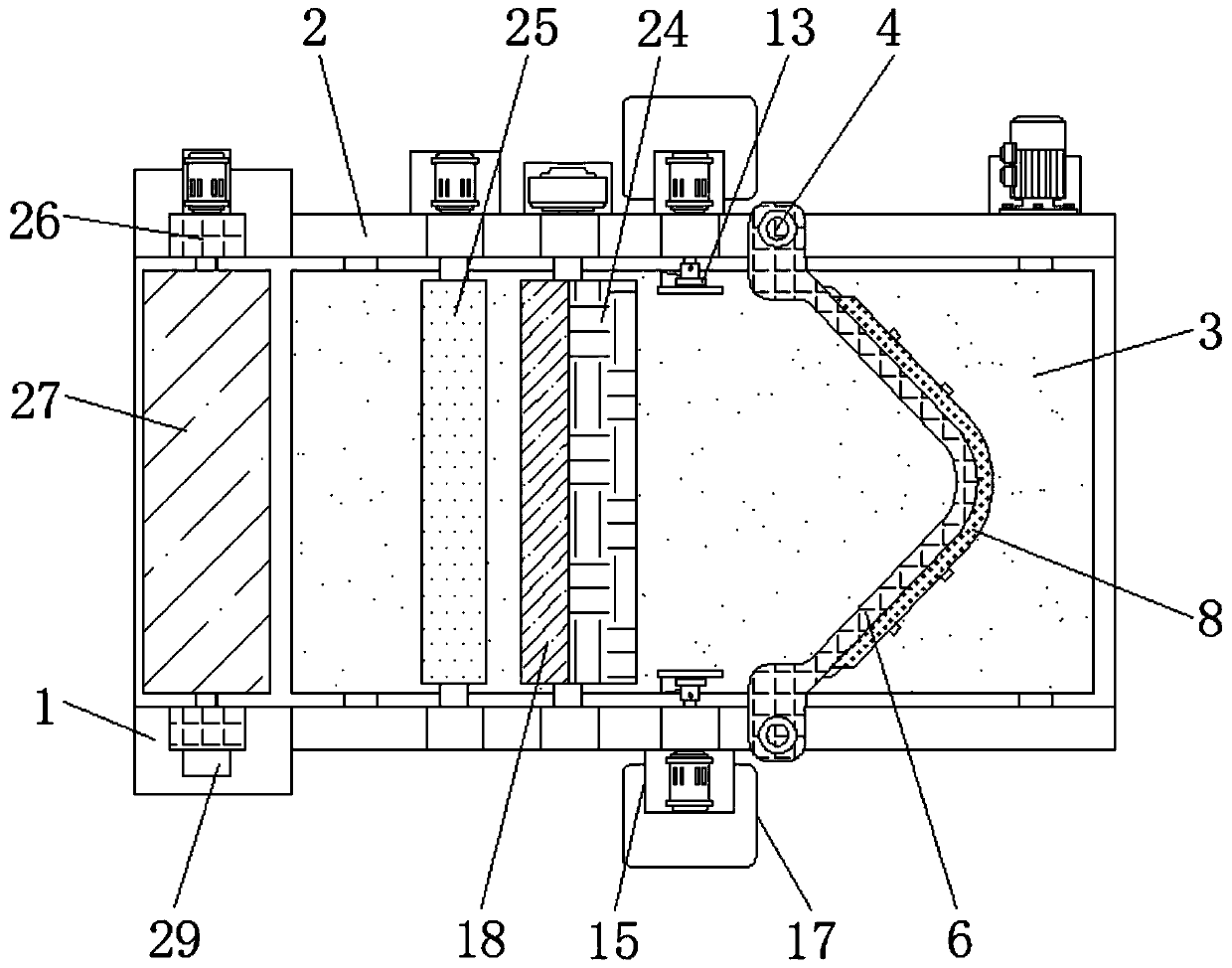

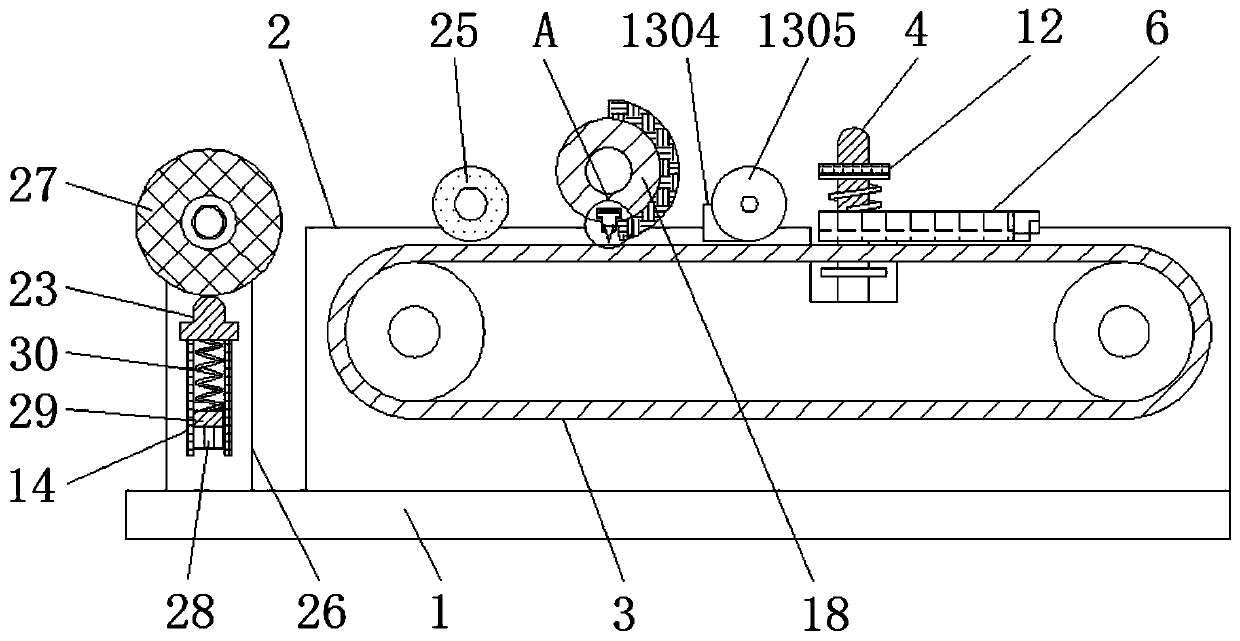

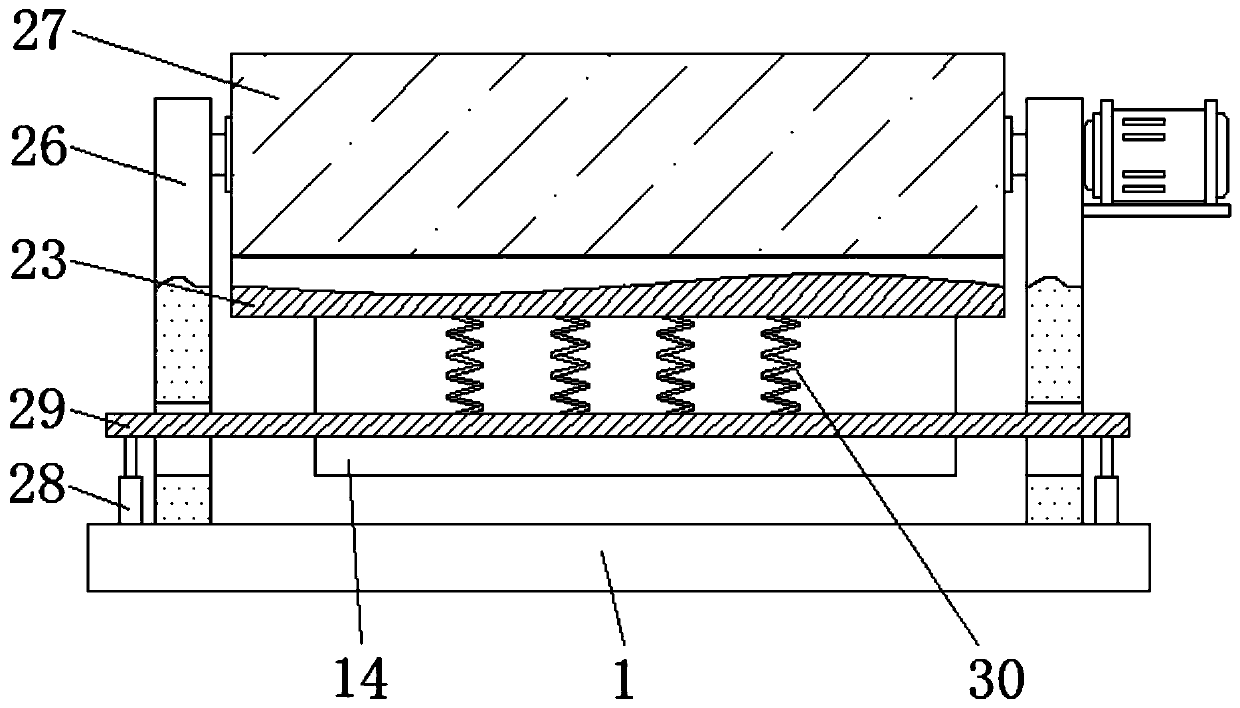

[0030] Such as Figure 1-Figure 7 As shown, a mixed weaving loom includes a base 1, a mounting frame 2, a conveyor belt 3, a mounting rod 4, a supporting spring 5, a spreading plate 6, a fixing buckle 7, a mounting bar 8, a brush 9, and a squeeze spring 10. Squeeze piece 11, adjusting block 12, trimming device 13, limit plate 14, bearing seat 15, through hole 16, vacuum cleaner 17, cutting roller 18, installation groove 19, return spring 20, fixing block 21, cutting knife 22. Extrusion bar 23, rubber pad 24, conveying roller 25, winding frame 26, winding cloth 27, hydraulic telescopic rod 28, support plate 29 and decompression spring 30, the front and rear ends of the upper surface of the base 1 are welded and fixed There is a mounting frame 2, and a conveyor belt 3 is installed on the inside of the mounting frame 2, a mounting rod 4 is fixed on the upper right end of the mounting frame 2, and a supporting spring 5 is nested outside the mounting rod 4, and a spreading plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com