Shear wall with embedded heat-preservation and waterproof block, and construction method of shear wall

A construction method and shear wall technology, applied in thermal insulation, wall, climate change adaptation and other directions, can solve the problems of small indoor usable area, easy to mold, poor external thermal insulation and fire resistance, etc., and achieve good thermal insulation and waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

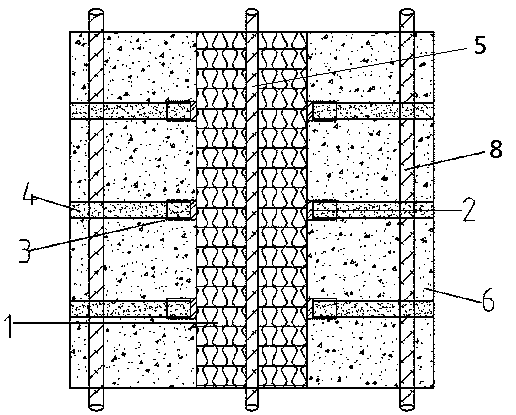

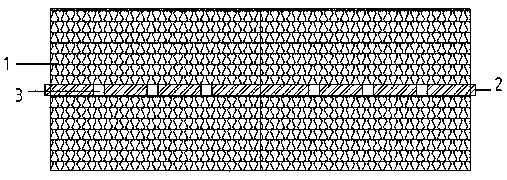

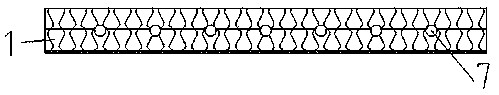

[0025] A shear wall with built-in thermal insulation and waterproof blocks, including thermal insulation and waterproof blocks 1 sandwiched between the concrete 6 of the shear wall on both sides, a steel bar 2 arranged horizontally and centrally on both sides of the thermal insulation and waterproof block 1, the steel A plurality of fixing sleeves 3 are evenly arranged on the bar 2 , and support ribs 4 are inserted in the fixing sleeves 3 , and the outer ends of the support ribs 4 protrude to the outside of the outer steel bars 8 . The surfaces of both sides of the thermal insulation and waterproof block 1 are coated with a polyurethane waterproof paint layer. A middle row of steel bars 5 is inserted in the middle of the thermal insulation and waterproof block 1, and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com