Flexible manufacturing system based on C2M mode

A flexible manufacturing system and flexible manufacturing technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of large land occupation, rapid adaptation to different products or parts processing requirements, and high investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention discloses a flexible manufacturing system based on the C2M mode. The specific implementation manner of the present invention will be further described below in combination with preferred embodiments.

[0021] preferred embodiment.

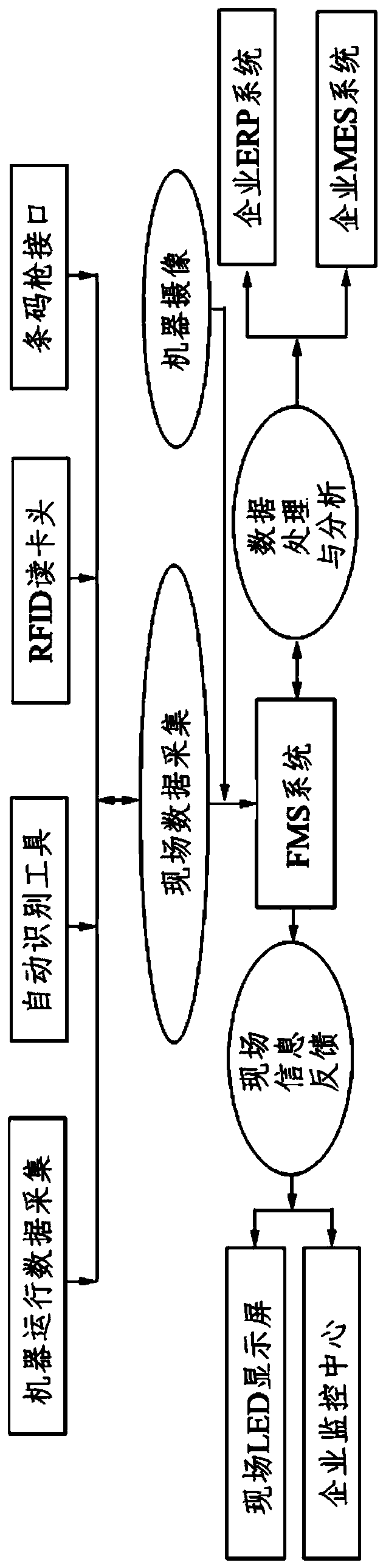

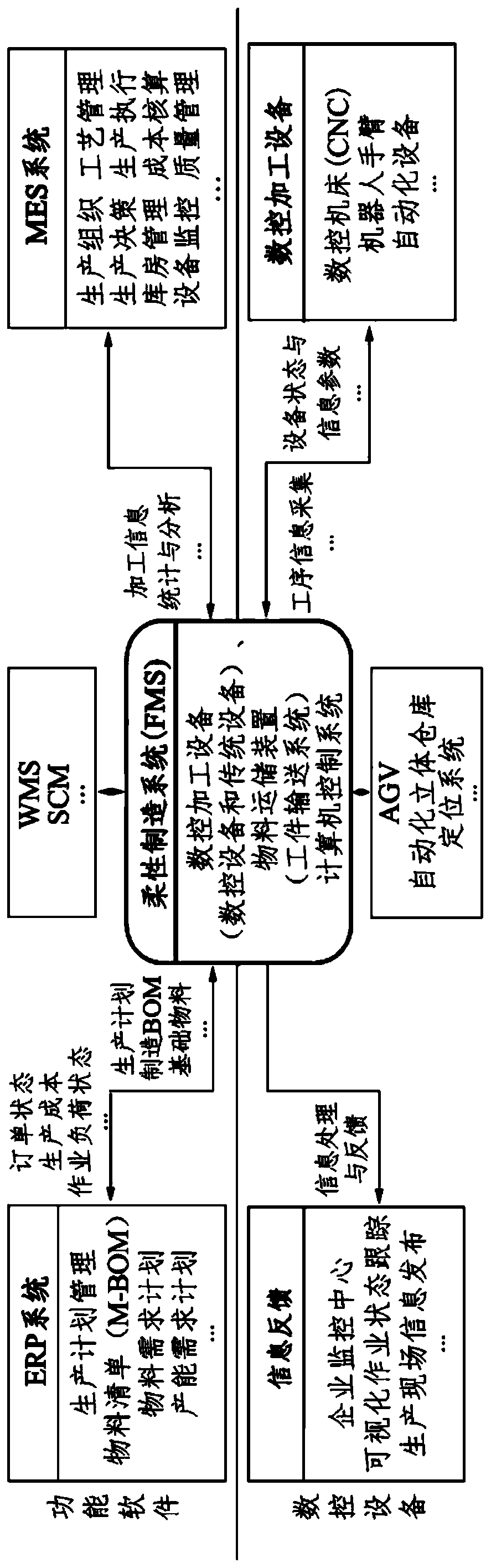

[0022] see attached figure 1 and figure 2 , figure 1 It shows the information integration method of the flexible manufacturing system based on the C2M mode, figure 2 It shows the workshop control visualization process of the flexible manufacturing system based on the C2M mode.

[0023] Preferably, the flexible manufacturing system based on C2M mode is used to integrate functional software and peripheral equipment for production, wherein:

[0024] The flexible manufacturing system based on the C2M mode interacts bidirectionally with the functional software for production to obtain flexible manufacturing data information collected and generated by the functional software for production;

[0025] The C2M-based flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com