Micro-nano fiber mode-locking device and preparation method thereof, and all-fiber laser device

A micro-nano optical fiber and mode-locking technology, which is applied in the laser field, can solve the problems of complex preparation process of saturable absorbers, high cost of micro-nano optical fiber preparation, and low yield, so as to reduce the risk of easy breakage, reduce manufacturing difficulty and The effect of high cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

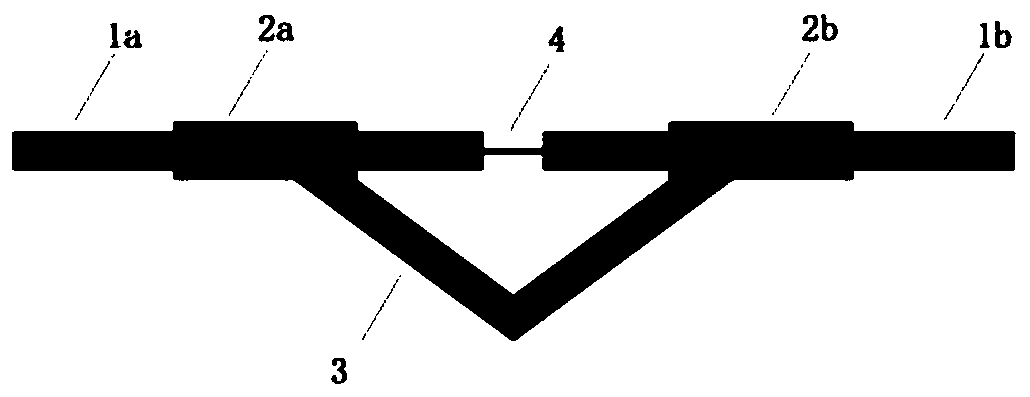

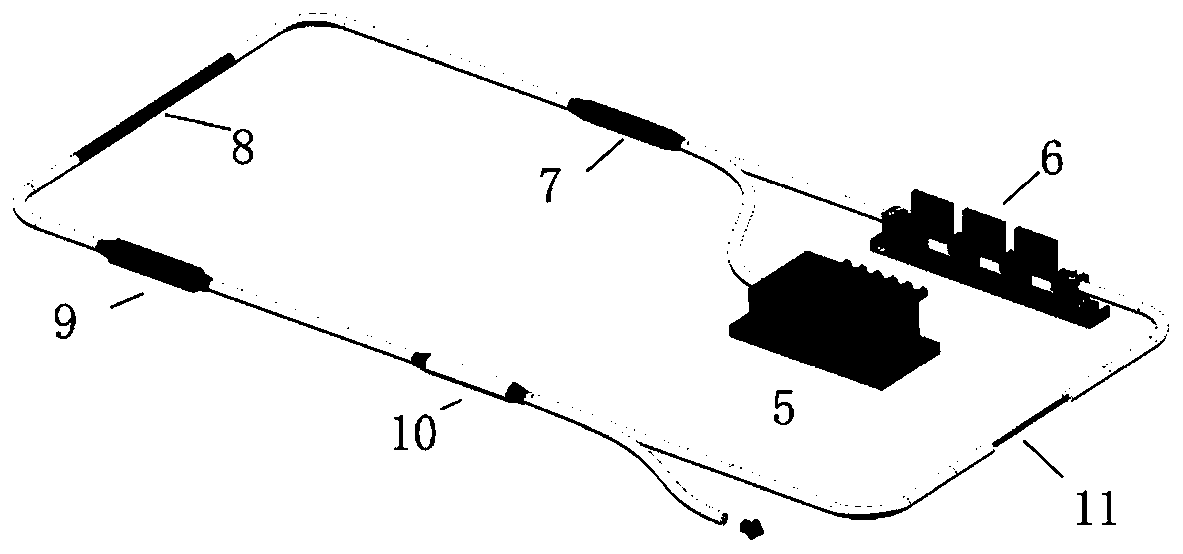

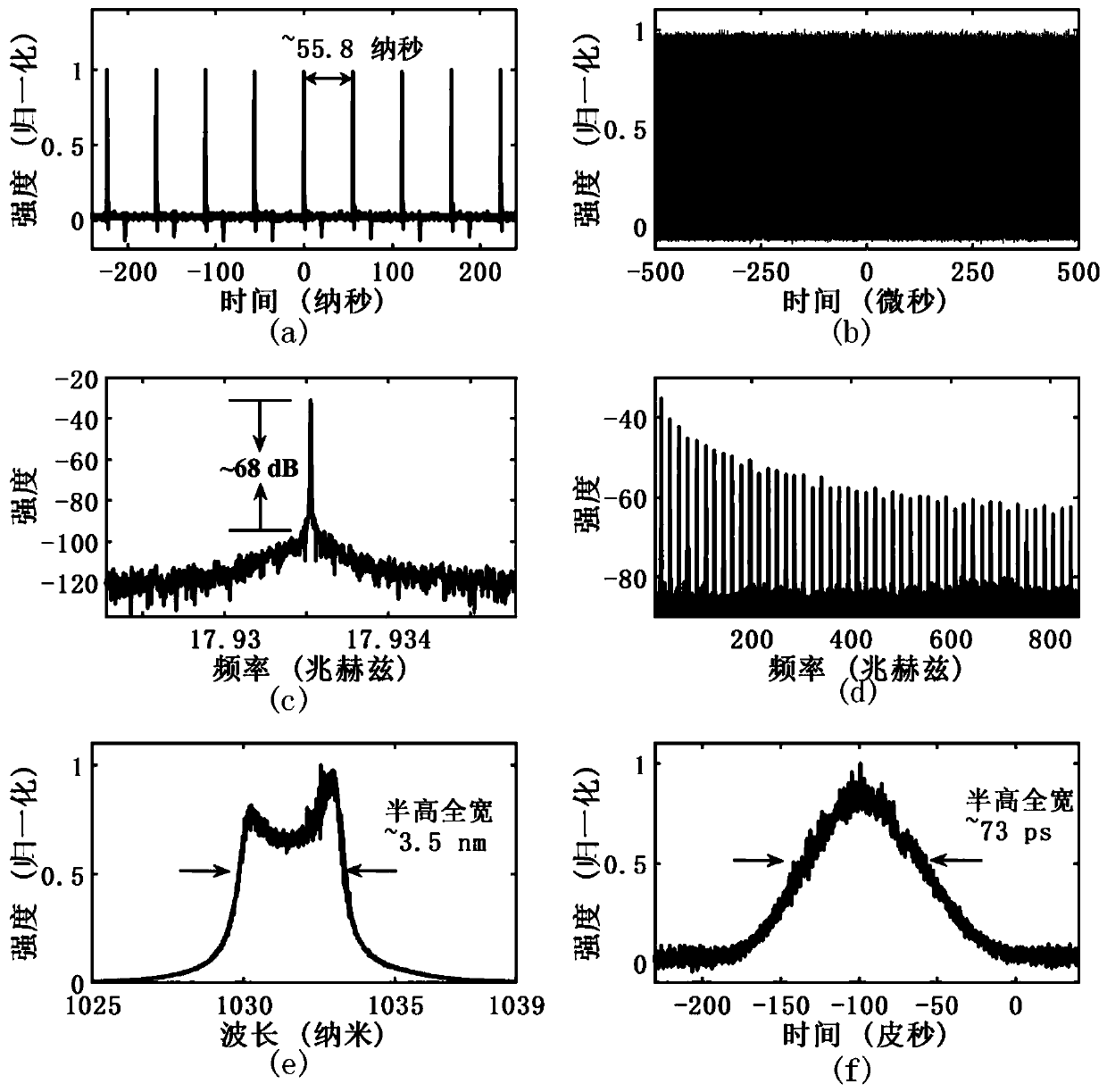

[0045] A method for preparing a micro-nano optical fiber mode-locking device provided in this embodiment includes steps:

[0046] S1, preparing the micro-nano optical fiber segment, including the following specific steps:

[0047] S1-1. Prepare common commercial single-mode optical fiber, use fiber stripping pliers to peel off the coating layer of common commercial single-mode optical fiber located in the middle part, and obtain the optical fiber whose middle part is the bare optical fiber segment, and wipe the fiber with alcohol-soaked fiber wiping paper Wipe off any debris remaining on the bare fiber section.

[0048] In this embodiment, the common commercial single-mode optical fiber used is a commercial Corning optical fiber; the length of the bare optical fiber section is 5-10 mm.

[0049] In this embodiment, before corroding the bare fiber segment on the optical fiber whose middle part is a bare fiber segment, a step is further included: fixing the optical fiber whose mid...

Embodiment 2

[0067] A method for preparing a micro-nano optical fiber mode-locking device provided in this embodiment includes steps:

[0068] S1, preparing the micro-nano optical fiber segment, including the following specific steps:

[0069] S1-1. Prepare common commercial single-mode optical fiber, use fiber stripping pliers to peel off the coating layer of common commercial single-mode optical fiber located in the middle part, and obtain the optical fiber whose middle part is the bare optical fiber segment, and wipe the fiber with alcohol-soaked fiber wiping paper Wipe off any debris remaining on the bare fiber section.

[0070] In this embodiment, the common commercial single-mode optical fiber used is commercial Corning optical fiber; the length of the bare optical fiber section is 3-5 mm.

[0071] In this embodiment, before corroding the bare fiber segment on the optical fiber whose middle part is a bare fiber segment, a step is further included: fixing the optical fiber whose midd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com