A kind of industrial robot and using method thereof

An industrial robot and turning mechanism technology, applied in the directions of manipulators, manufacturing tools, conveyor objects, etc., can solve the problems of low production efficiency of manual turning operations, easy to bump into operators or workpieces, and inability to realize production lines, so as to improve the turnover. Surface efficiency, improve overall efficiency, simple and compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

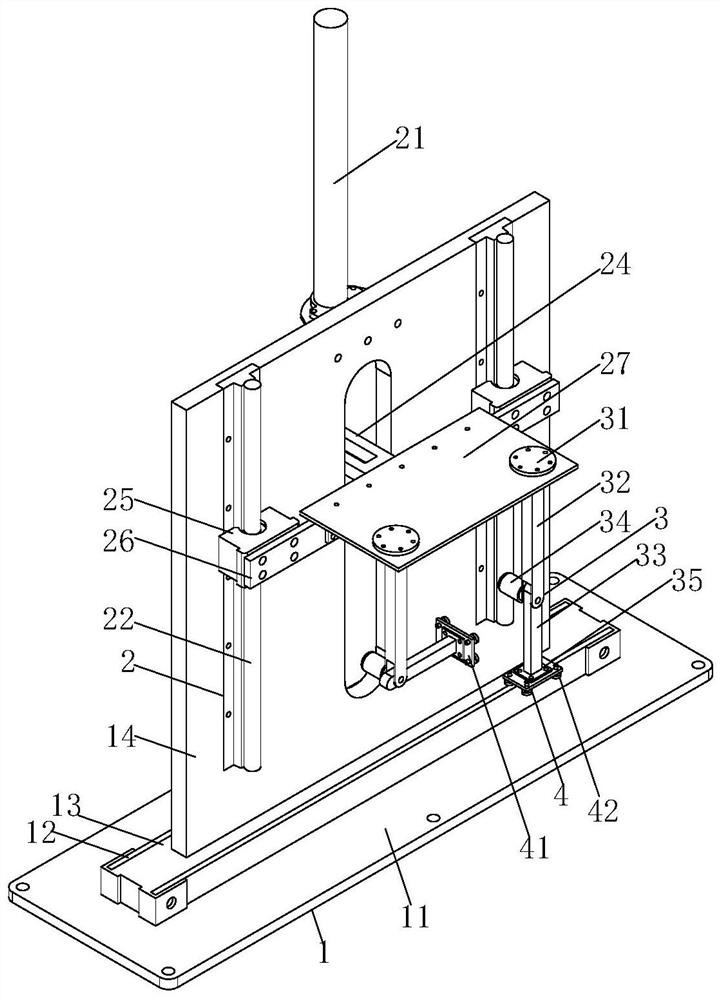

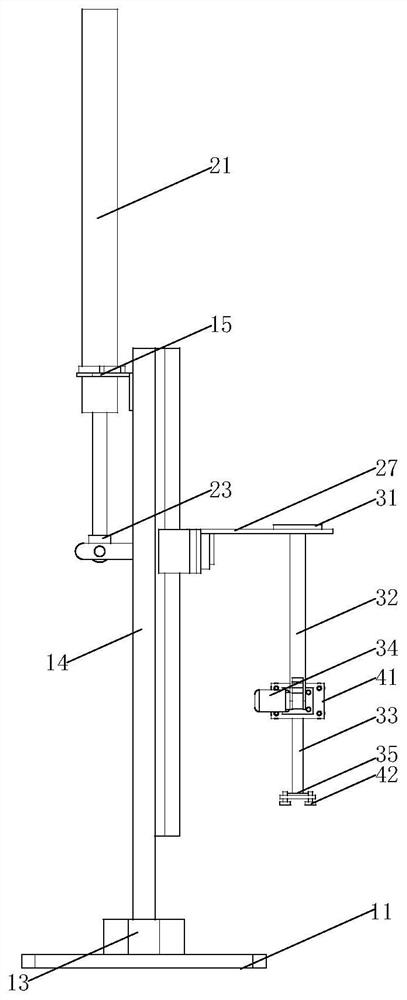

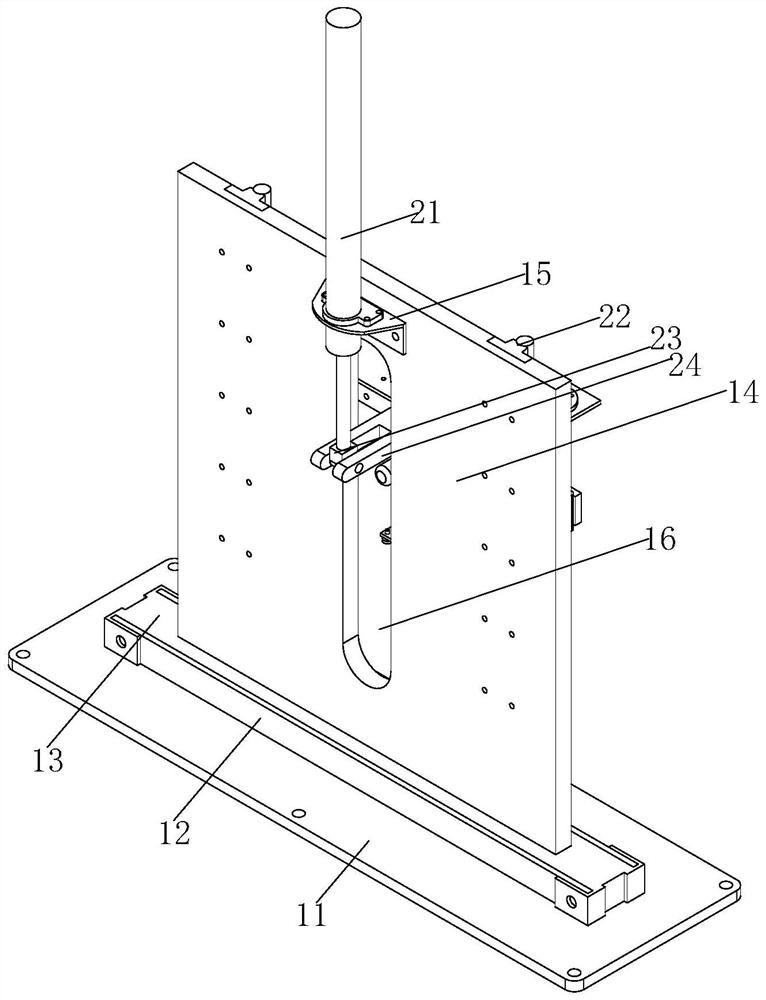

[0034] see Figure 1-4 , the present invention provides the following technical solutions: a new type of industrial robot, including a support assembly 1, a lifting mechanism 2, two turning mechanisms 3 and two fixing mechanisms 4, the lifting mechanism 2 is fixed on the support assembly 1, two The turning mechanism 3 is fixed on the lifting mechanism 2, and the two fixing mechanisms 4 are respectively fixed on the corresponding turning mechanism 3. By fixing the support assembly 1 on one side of the conveyor belt, the lifting mechanism 2, the turning mechanism 3 and the fixing mechanism The cooperation of 4 can quickly realize the turning over of materials. At the same time, the structure design of the device is simple and compact, which is convenient for installation. The turning operation steps are simple, and it is suitable for small enterprises to turn over small products. It not only improves the turning efficiency and reduces the labor intensity, but also improves the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com