Method using photoreduction to realize complete debromination of polybrominated aromatic compound

A technology of aromatic compounds and compounds, applied in the field of photochemical synthesis, can solve problems such as strong toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

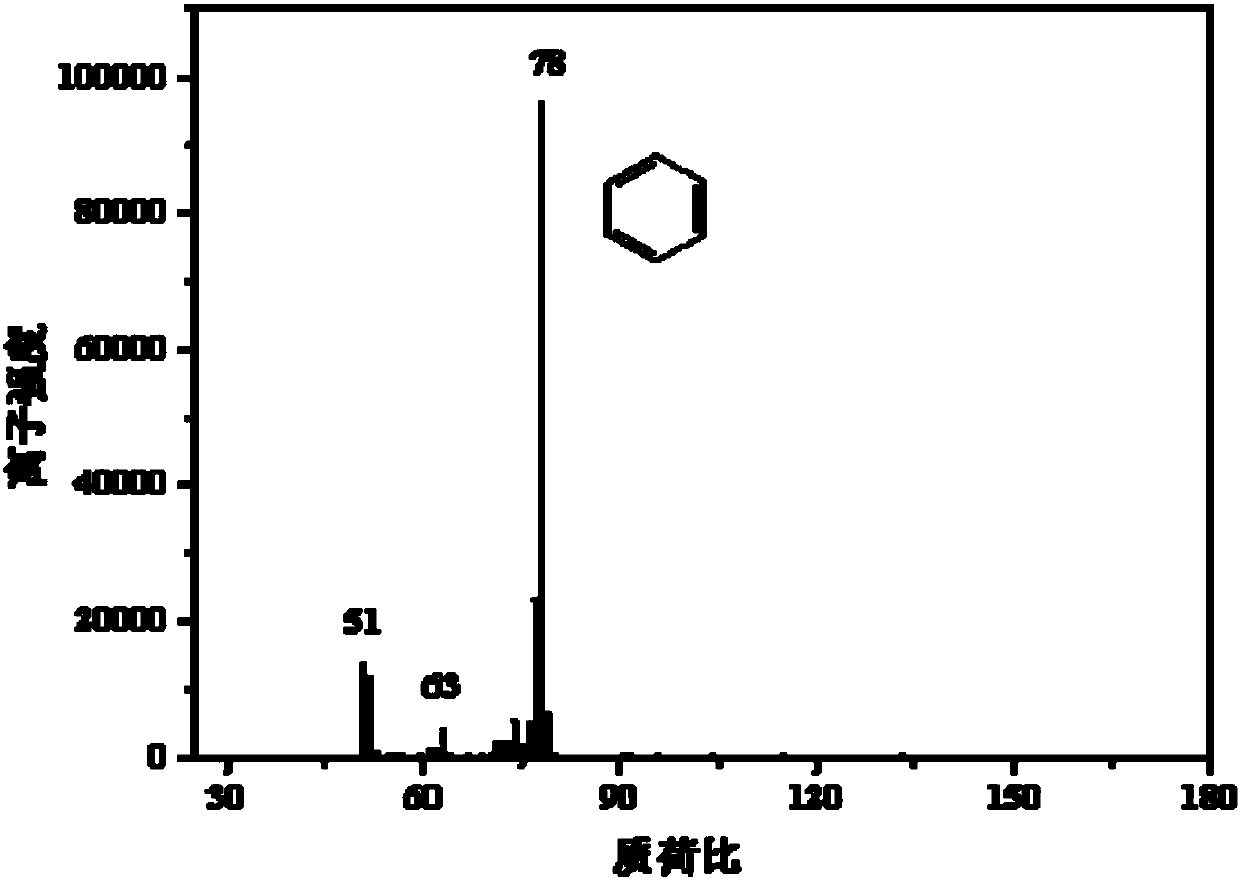

[0040] Add N,N-dimethylacetamide: hexabromobenzene at a molar ratio of 50:1 to the photochemical reactor filled with acetonitrile solvent. Then the photoreactor was sealed and ultrasonicated for 10 minutes to make the solution uniformly mixed. The photochemical reactor was deoxygenated with high-purity argon gas, and the photochemical reactor was stirred while removing oxygen. After the deoxygenation is completed, continue to stir under the same conditions and irradiate with ultraviolet light for 2 hours and then stop the reaction. The main product of the reaction is benzene.

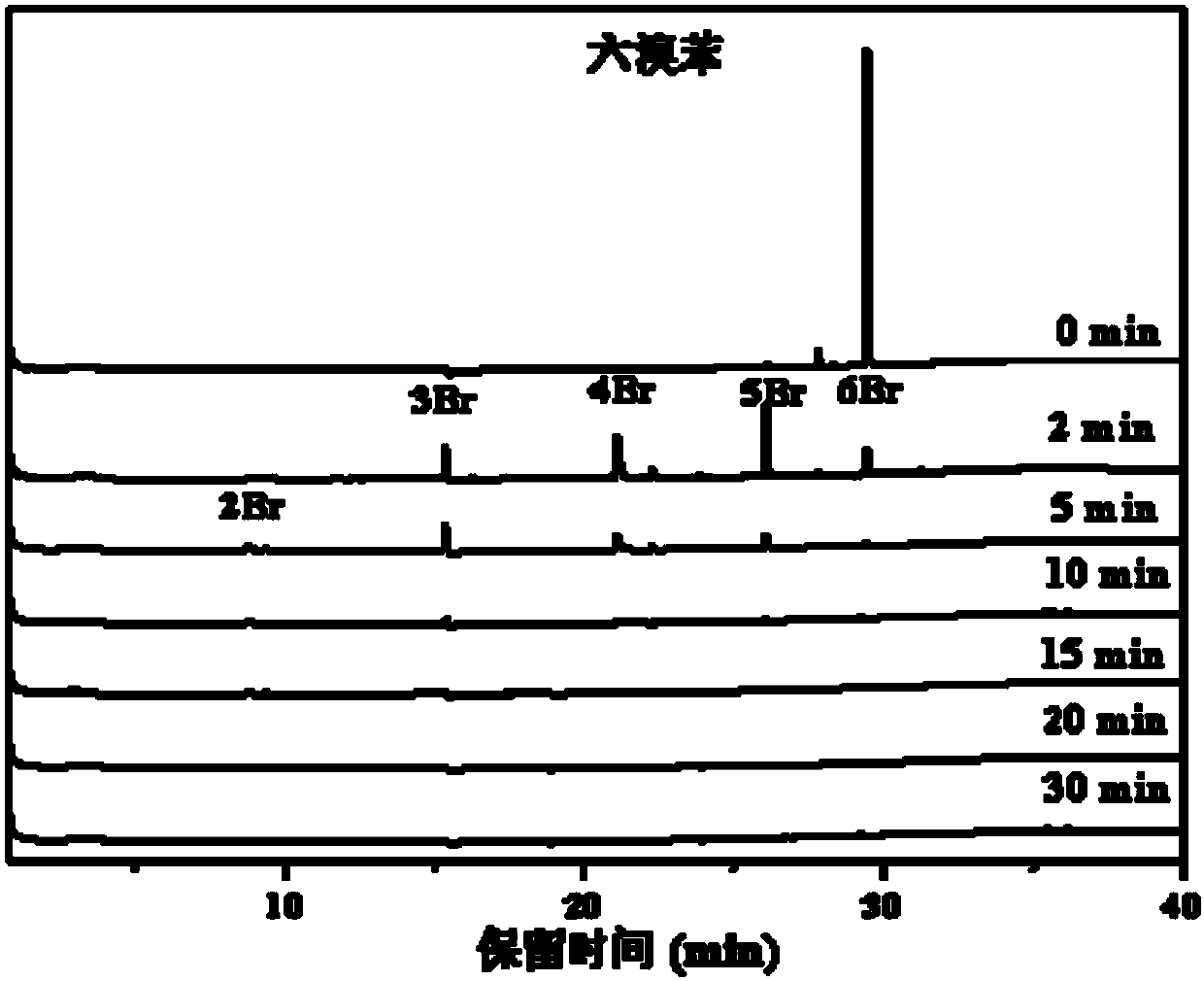

[0041] Use GC-μECD to detect the degradation products of hexabromobenzene (HBB) at different irradiation times, such as figure 1 As shown, it can be seen from the figure that with the progress of light, a large amount of pentabromobenzene, tetrabromobenzene, and tribromobenzene appear in gas spectrum detection at two minutes, and all hexabromobenzene is converted and dibromobenzene appears at five minutes....

Embodiment 2

[0044] Add N,N-dimethylaniline: decabromodiphenyl to a photochemical reactor filled with acetonitrile solvent at a molar ratio of 50:1. Then the photoreactor was sealed and ultrasonicated for 10 minutes to make the solution uniformly mixed. The photochemical reactor was deoxygenated with high-purity argon gas, and the photochemical reactor was stirred while removing oxygen. After the deoxygenation is completed, continue to stir under the same conditions and irradiate with ultraviolet light for 4 hours to stop the reaction. The main product of the reaction is biphenyl.

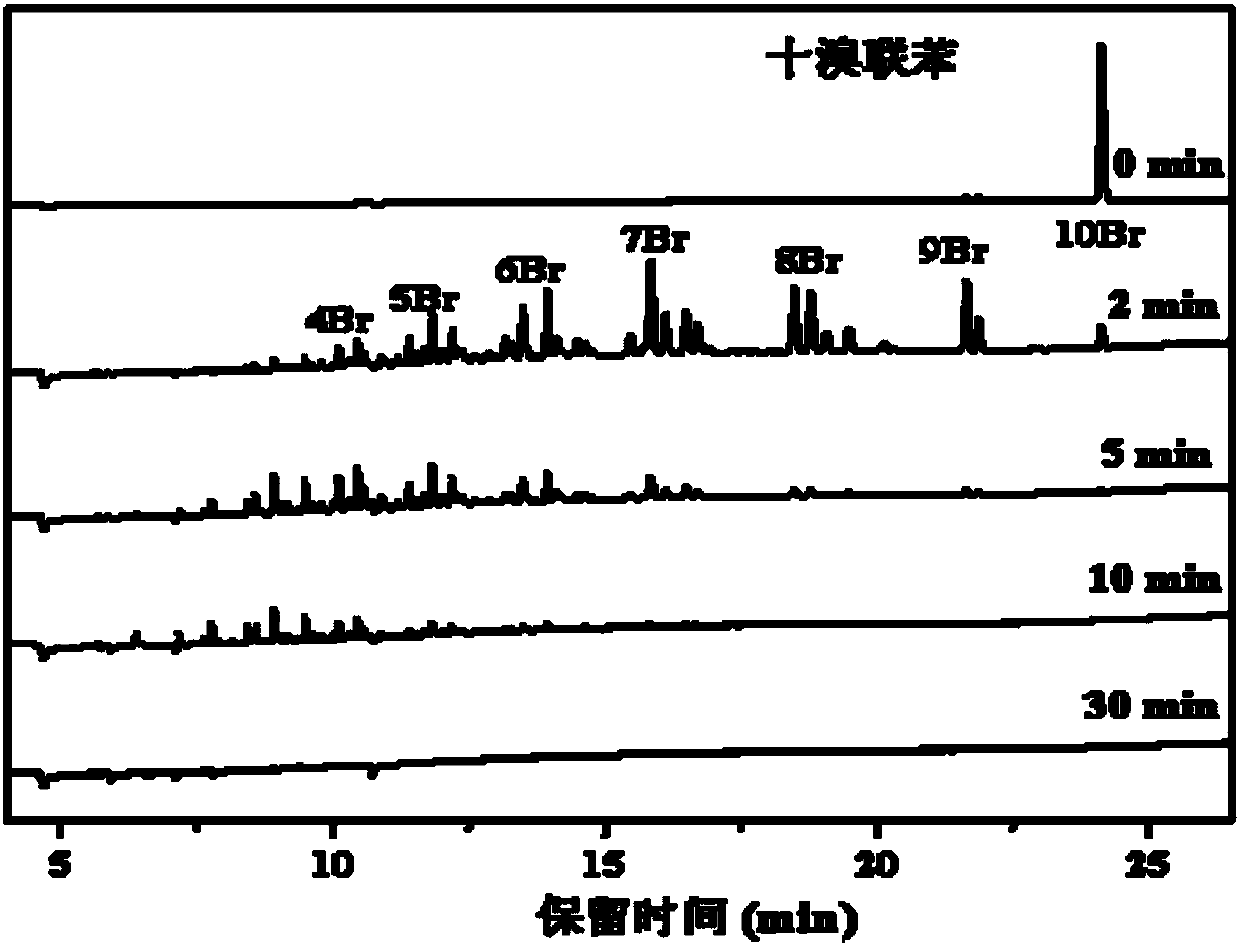

[0045] Use GC-μECD to detect the degradation products of decabromobiphenyl (DBB) at different irradiation times, such as image 3 As shown, it can be seen from the figure that with the progress of light, decabrombiphenyl is converted in a large amount at two minutes and a series of low brominated products (4-9 bromine) are generated. Continue to illuminate, and the low-brominated products will continue to transfo...

Embodiment 3

[0048] Add N,N,N',N'-tetramethyl-p-phenylenediamine: tetrabromodiphenyl ether at a molar ratio of 50:1 to a photochemical reactor filled with methanol solvent. Then the photoreactor was sealed and ultrasonicated for 10 minutes to make the solution uniformly mixed. The photochemical reactor was deoxygenated with high-purity argon gas, and the photochemical reactor was stirred while removing oxygen. After the deoxygenation is completed, continue to stir under the same conditions and irradiate with visible light for 4 hours to stop the reaction. The main product of the reaction is biphenyl. The conversion rate of the reactant tetrabromodiphenyl ether was 100%, and the yield of diphenyl ether was 48%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com