Moving frame type unbalanced load resisting hydraulic cylinder

A technology for moving frames and hydraulic cylinders, applied in the field of hydraulic cylinders, can solve problems such as poor anti-eccentric load effect and inability to solve the impact of hydraulic cylinder performance, and achieve the effects of reducing friction, large radial eccentric loads, and improving bearing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

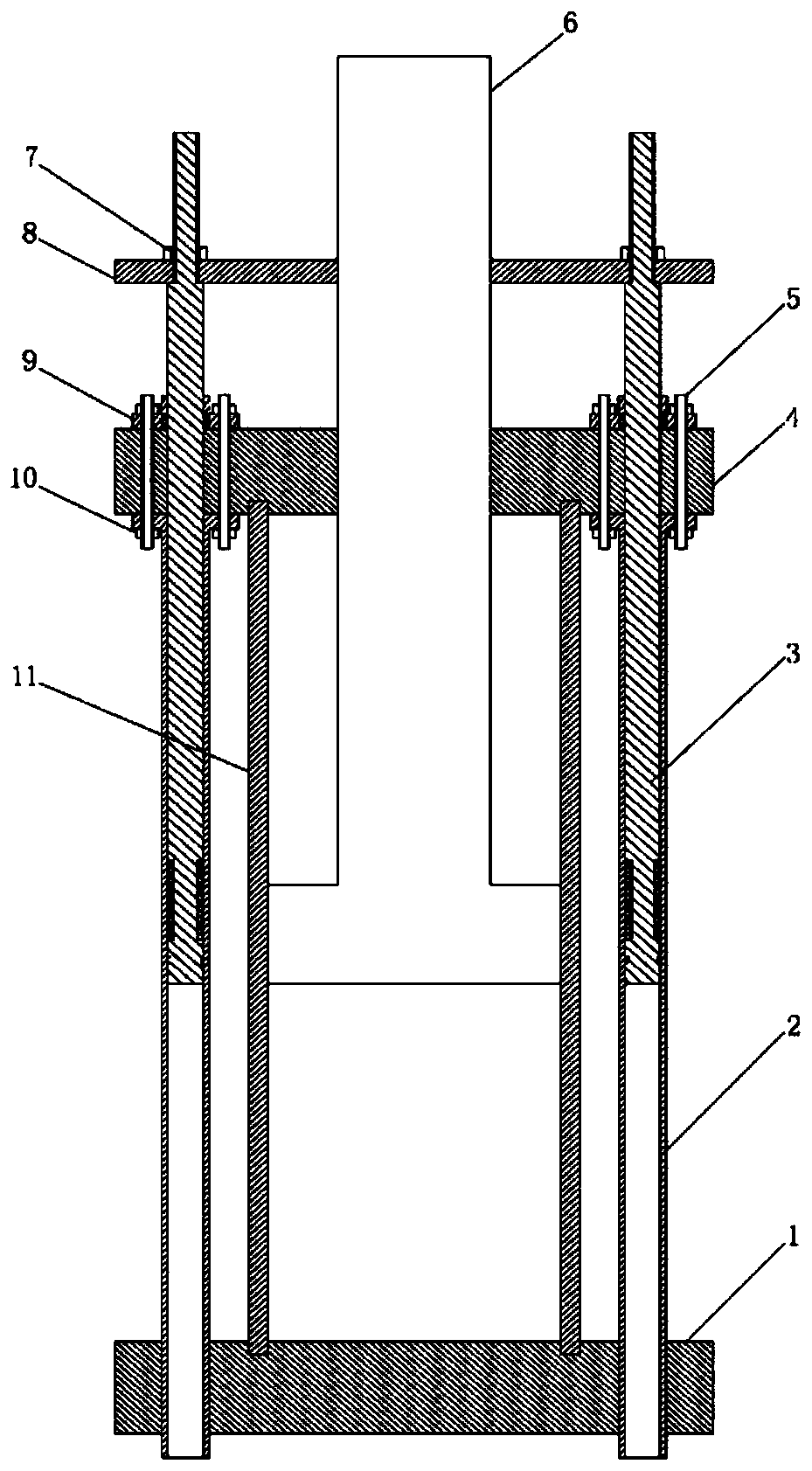

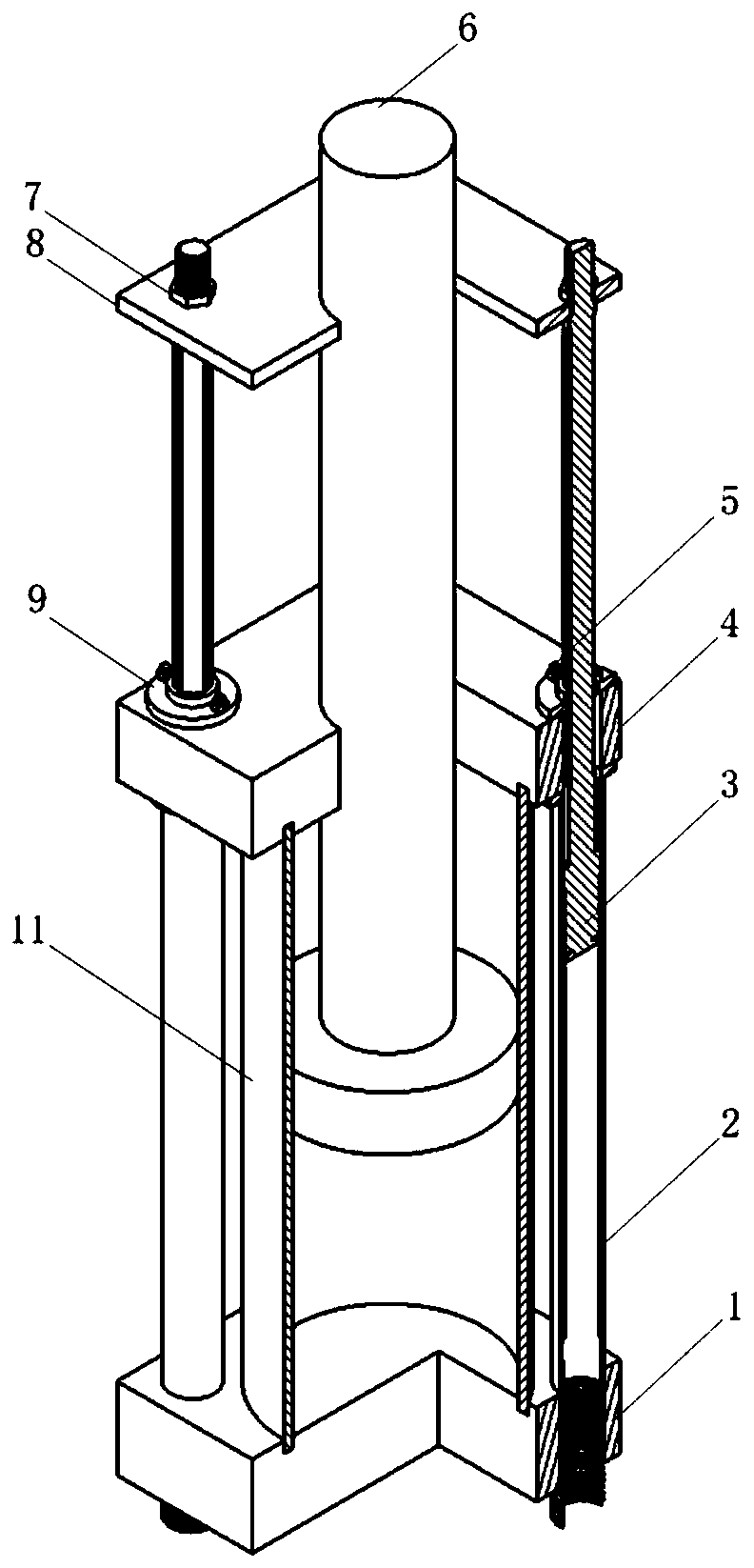

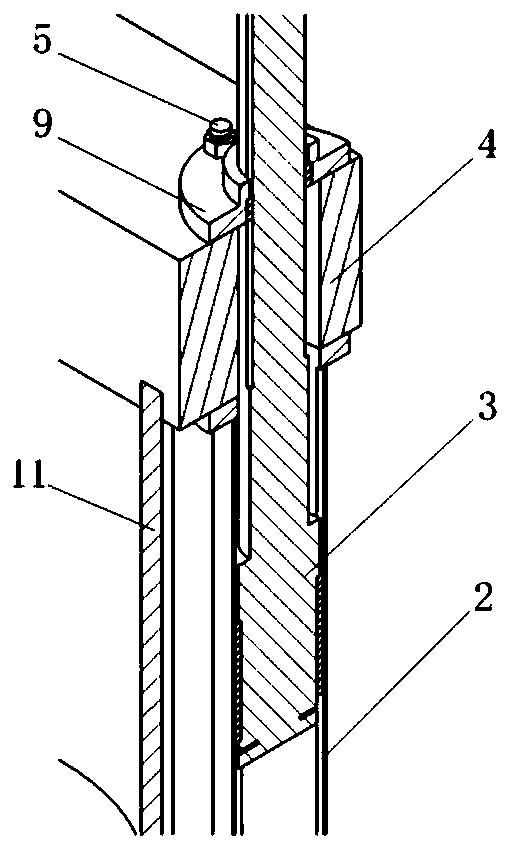

[0031] Such as figure 1 with 2 As shown, the present invention provides a mobile frame type anti-eccentric load hydraulic cylinder, including a cylinder head 1, a side support tube 2, a side support piston 3, a cylinder head 4, a piston 6, a connecting frame 8, a linear bearing 9 and a cylinder barrel 11 Composition, four side branch cylinders and connecting frames that can move with the piston are added around the traditional hydraulic cylinder, and a linear bearing 9 is installed at the end of the side branch piston. The bottom end of the side support tube 2 is fixed to the hydraulic cylinder head 1 in the form of threads, and the top end is fixed to the cylinder head 4 with a stud 5 and a hex nut 10. Track grooves that allow the balls to roll.

[0032] It should be pointed out that multiple side branch cylinders can be evenly distributed around the main piston rod within the allowable range. In this embodiment, only 4 side branch cylinders are analyzed, and changes based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com