Vehicle brake and energy dissipating device for vehicle brake

A technology for energy dissipation and vehicle braking, which is applied in the deceleration device of DC motor, vehicle components, transportation and packaging, etc. It can solve the problems of DC bus voltage increase and motor burning, and reduce ripple current and increase The effect of minimizing distributed capacitance, line impedance and stray inductance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better understand the present invention, the technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

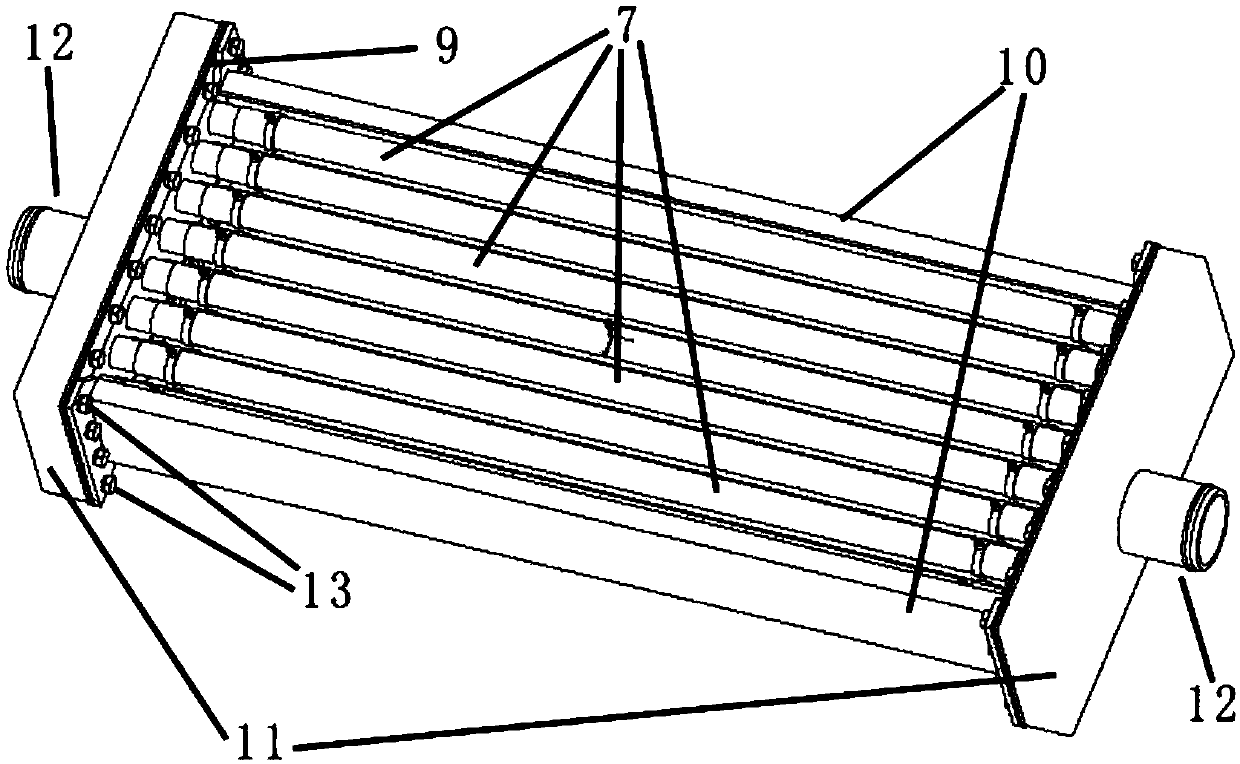

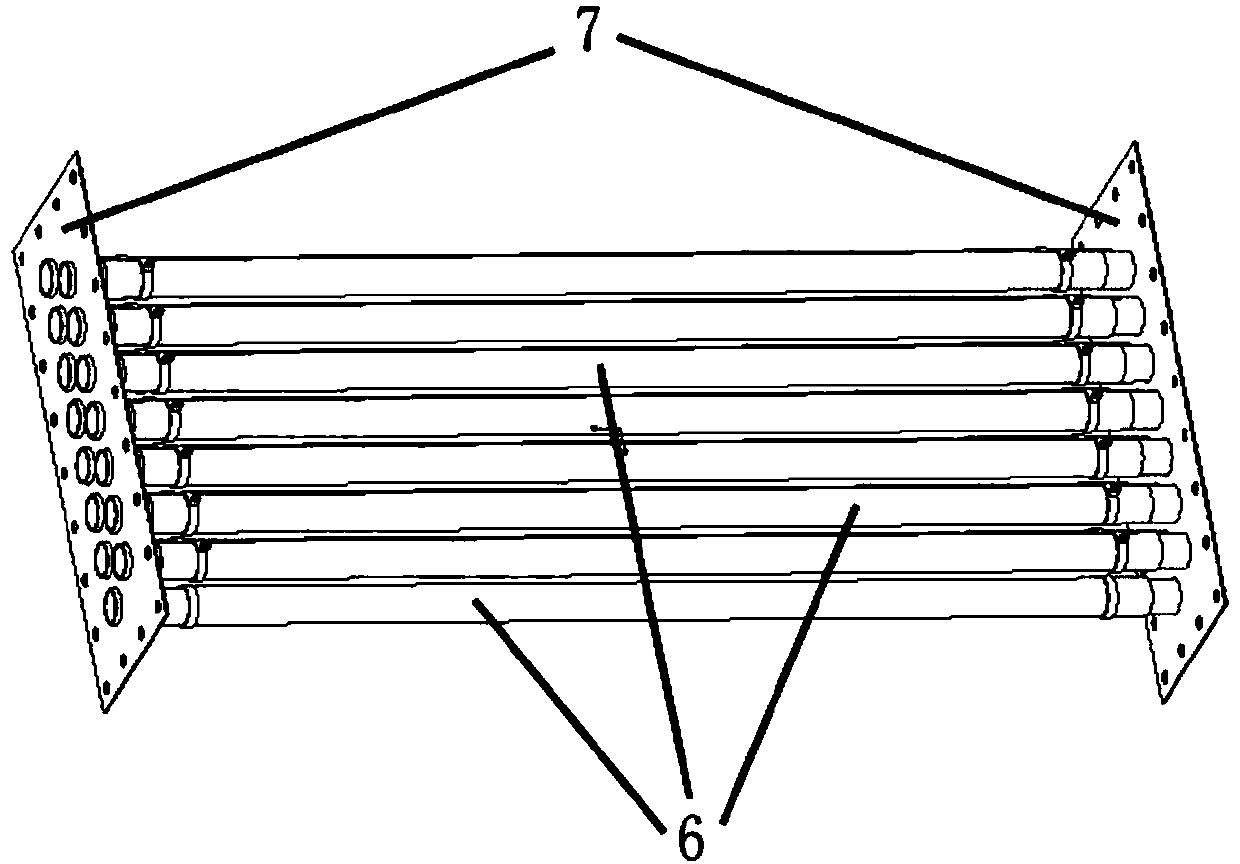

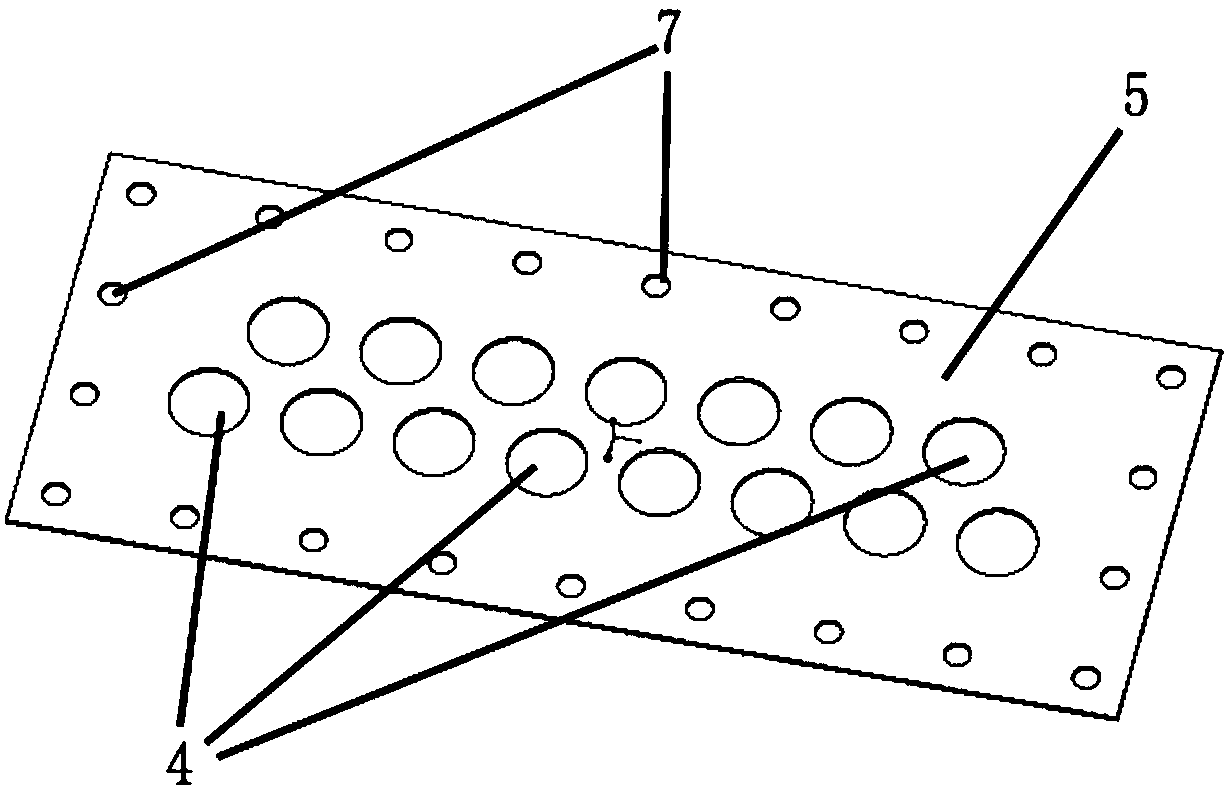

[0050] Such as Figure 1 to Figure 4As shown, in the energy dissipation device provided by the present invention, the brake includes a DC bus 8, and the dissipation device includes: a collector chamber 11 arranged in parallel and a protective plate 10 perpendicular to the collector chamber 11. The dissipation frame, the inlet and outlet 12 arranged outside the collecting chamber 11, and the cooling core assembly arranged in parallel between the protective plates 10 and communicated with the inlet and outlet 12, the cooling core assembly includes: plate 6 and the liquid-cooled braking resistor tube 7 vertically arranged on the forming plate 6 and whose two ends communicate with the opening on the forming plate 6; the protection plate 10 plays a role in ensuring the rigidity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com