Fry breeding net cage

A technology for cages and fry, applied in fish farming, application, climate change adaptation, etc., can solve the problems of poor ability to resist typhoons, poor ability to resist wind and waves, lack of protective framework for cages, etc., to achieve strong wind and wave resistance, Strong cleaning ability, reducing the effect of fry breeding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

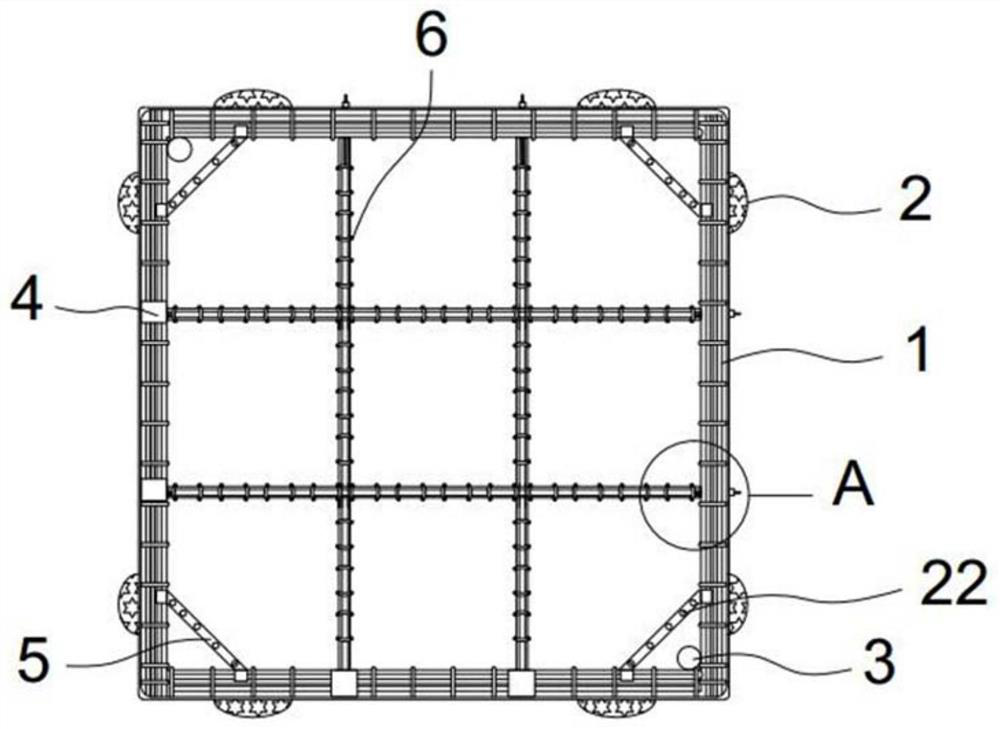

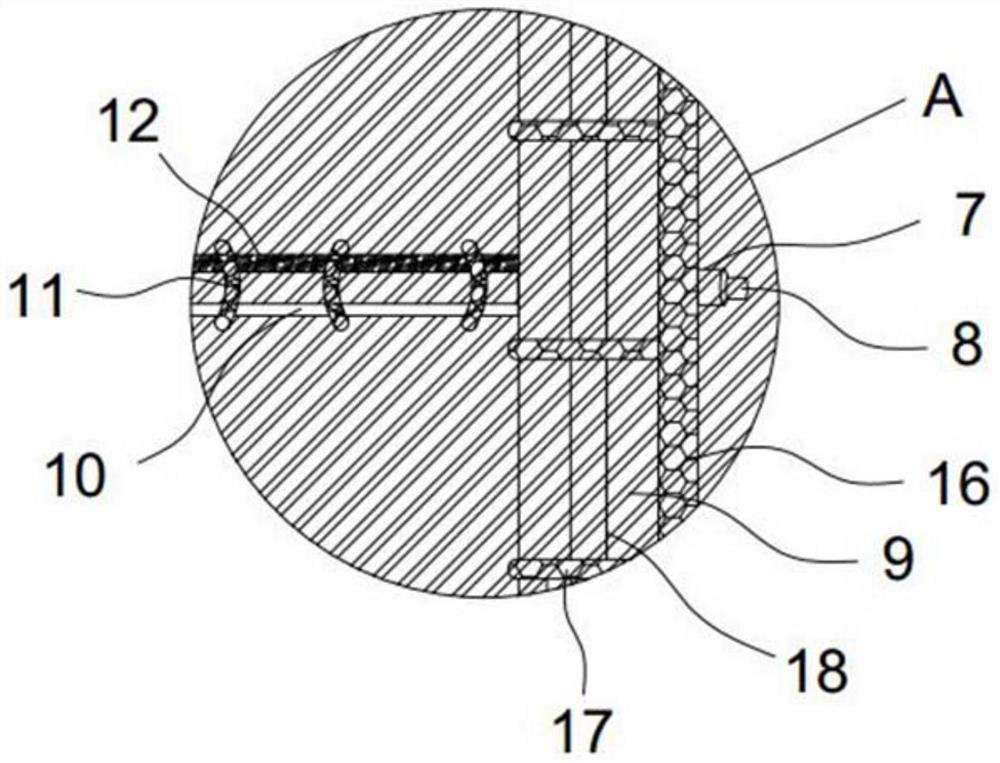

[0024] see Figure 1-4 As shown, the fish fry breeding net cage includes a net cage frame 1, and the outer peripheral surface of the net cage frame 1 is evenly distributed with buoys 2, and the interior of the net cage frame 1 is provided with criss-cross sub-grids 6, and the net cage frame 1 includes steel pipes 16, The steel pipe 16 communicates with the water pump 3 provided in the net cage frame 1. A plurality of jet pipes 17 are distributed on the steel pipe 16, and buoys are evenly distributed on the outer peripheral surface of the net cage frame, so that the net cage can be suspended in water and carry out fry cultivation. There are criss-cross sub-grids inside the frame, which can realize the breeding of fry in the cage according to different specifications, and connect the steel pipe with the water pump set in the frame of the cage. There are multiple jet pipes distributed on the steel pipe, so that the water pump can drive the net The water in the box is pumped out a...

Embodiment 2

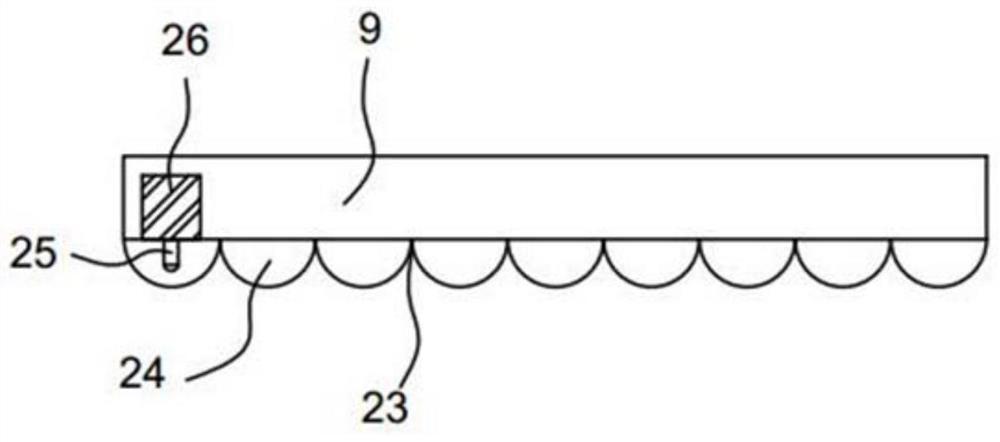

[0030] Such as Figure 5-6 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: sub-grid 6, including plastic round tube 12, a plurality of magnetic strips 11 are fixedly installed on the upper end of plastic round tube 12, and the adjacent magnetic strips 11 Magnetic mutual repulsion, plastic round pipe 12 one side is provided with the electromagnet rod 10 that is arranged in parallel, and plastic round pipe 12 lower end is connected with main net clothing 15, and electromagnet rod 10 lower end is connected with secondary net clothing 13, and electromagnet rod 10 one end is provided with crank connection Rod 7, is provided with electric control button 8 on crank connecting rod 7. A plurality of magnetic strips are fixedly installed on the upper end of the plastic round tube, and the magnetism between the adjacent magnetic strips repels each other. There is an electromagnet rod arranged in parallel on one side of the plastic round tube, so that...

Embodiment 3

[0035] The working principle of the fish fry culture net cage of the present invention is: the device is placed in the designated culture area to carry out fish fry culture, the water pump 3 is started, and the water in the net cage is pumped out and sprayed into the net cage again through the spray pipe 17 distributed on the steel pipe 16. During the process, the water outside the cage can increase the flow rate of water into the cage in a short time, promote the material exchange between the water layers in the cage, and make the distribution of nutrients in the cage even. There are 9 adjacent pedals. The fixed bar 5 that is provided with inclination has further strengthened the intensity of net cage framework, increases the wind and wave resistance ability of net cage, night, fixed bar 5 built-in insect light source 22 projections in the water, can attract microorganisms in water to enter in the net cage, so that fish fry look for Food, after 2-3 breeding cycles, by controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com