Preparation methods of polyisoprene low polymer, branched modifier and branched rare earth isoprene rubber

A technology of polyisoprene and isoprene is applied in the field of polyisoprene branching agent to achieve the effects of reducing dynamic viscosity, facilitating post-processing and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention can also provide a preparation method of the polyisoprene oligomer of the present invention, comprising: under the presence of an inert atmosphere and an alkyllithium initiator, the isoprene in the oligomerization solvent is oligomerized reaction. The conditions therein are as described above.

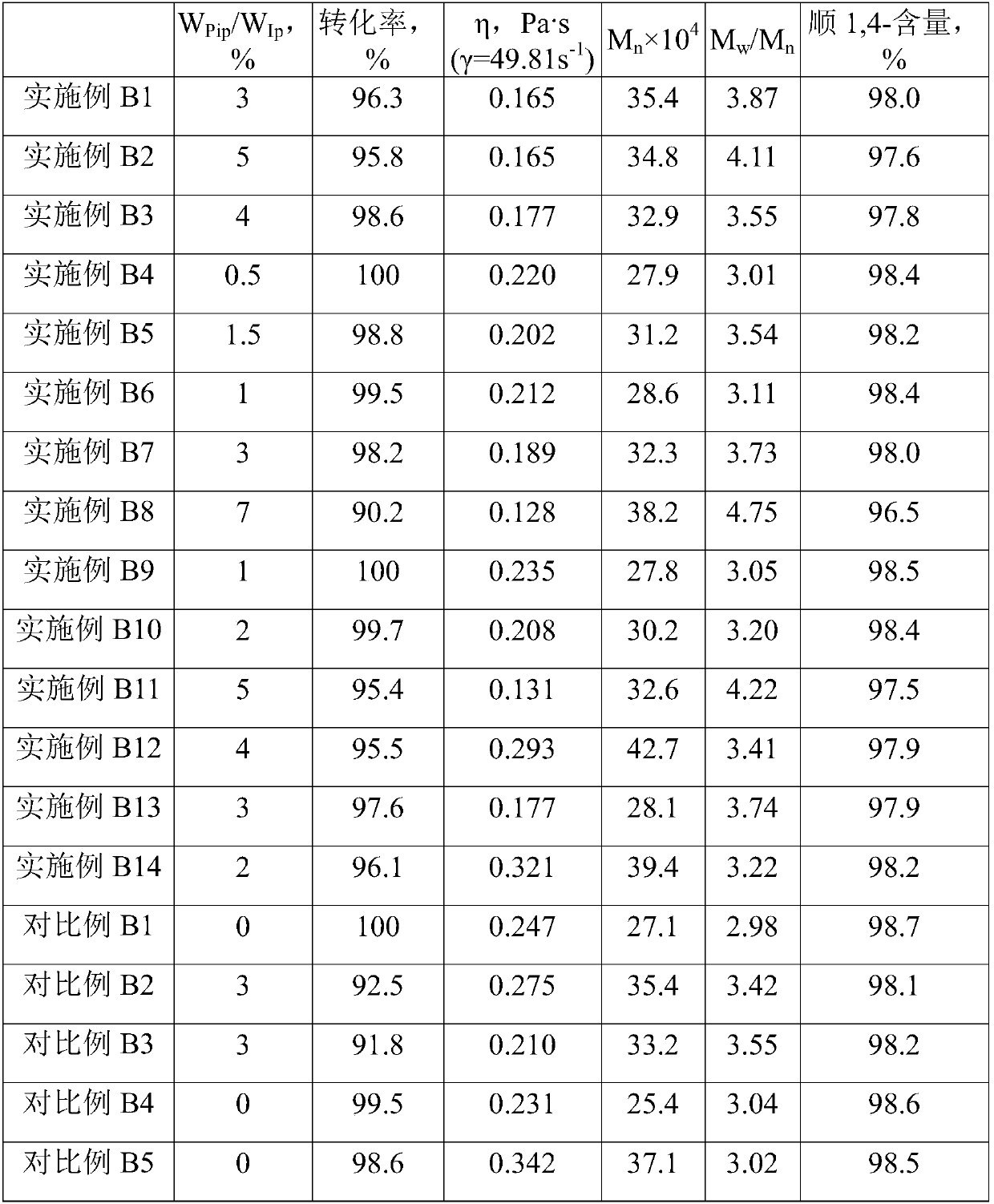

[0045] The third aspect of the present invention provides a method for preparing branched rare earth isoprene rubber, comprising:

[0046] In the presence of an inert atmosphere and a rare earth polymerization catalyst, the isoprene monomer in the polymerization solvent and the branched modifier of the present invention are subjected to polymerization reaction.

[0047] In the present invention, preferably, the concentration of the isoprene monomer in the polymerization solvent may be 8-20% by weight.

[0048] In the present invention, preferably, the branched modifier contains the aforementioned polyisoprene oligomer of the present invention, and the pol...

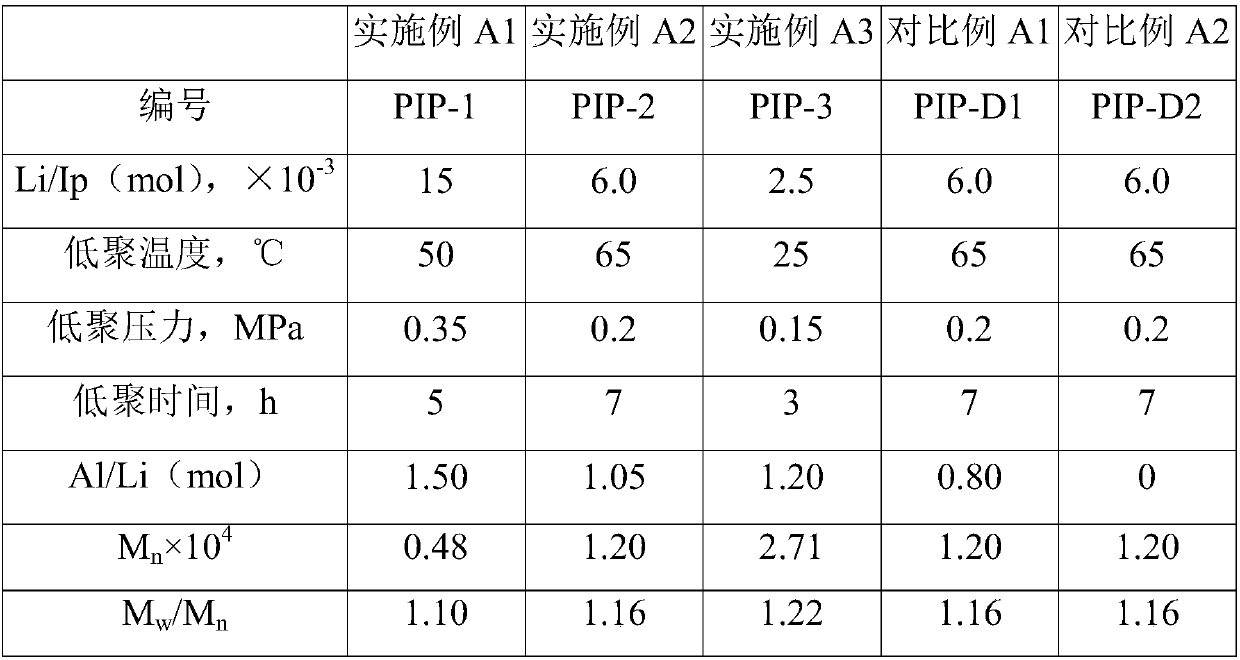

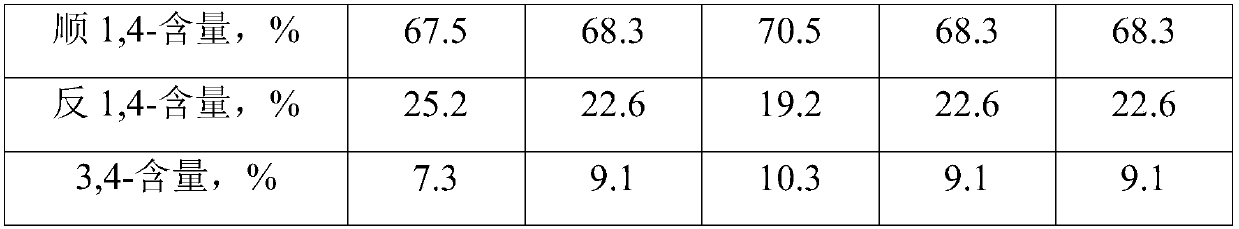

Embodiment A1-A3

[0078] Mark the 4 polymerization bottles as A0, A1, A2, A3, vacuumize them and bake them at high temperature, then fill them with high-purity nitrogen, and repeat this three times;

[0079] Add the same amount of hexane and isoprene into each polymerization bottle (the content of isoprene is 0.10 g isoprene / mL hexane, referred to as Ip). Take the polymerization bottle A0 as the trash-killing bottle, add 4-vinylpyridine as the indicator, and use nBuLi to calibrate the amount of impurities in the solution to obtain the amount of trash-killing.

[0080] Initiator nBuLi (abbreviated as Li) was added to polymerization bottles A1, A2 and A3 after deducting the amount of impurities. The metering of initiator nBuLi was according to the data of Li / Ip in Table 1. According to the oligomerization conditions in Table 1, the isoprene in the polymerization bottles A1, A2, and A3 is subjected to an oligomerization reaction, and after the reaction is completed, metered triisobutylaluminum (Al...

preparation example 1

[0091] Preparation of rare earth polymerization catalysts.

[0092] Add a certain amount of neodymium neodecanoate (abbreviation: Nd) and triisobutylaluminum (abbreviation: Al) to the catalyst preparation device under the protection of nitrogen, Al / Nd (mol) = 30:1; After 0.5h, add a certain amount of diethylaluminum chloride (abbreviation: Cl), Cl / Nd (mol) = 2.5:1, and continue to age at 30°C for 1h.

[0093] The obtained catalyst aging solution is designated as Cat-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com