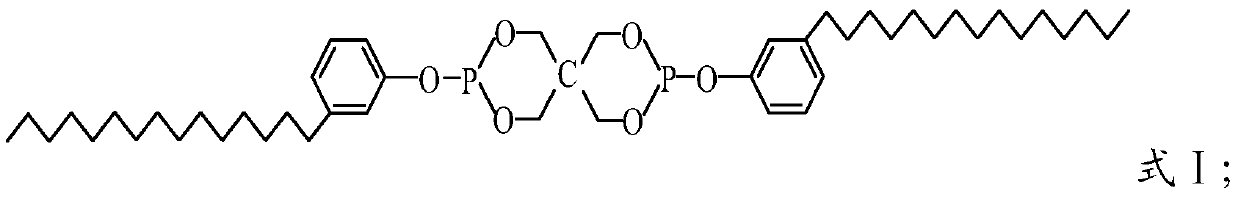

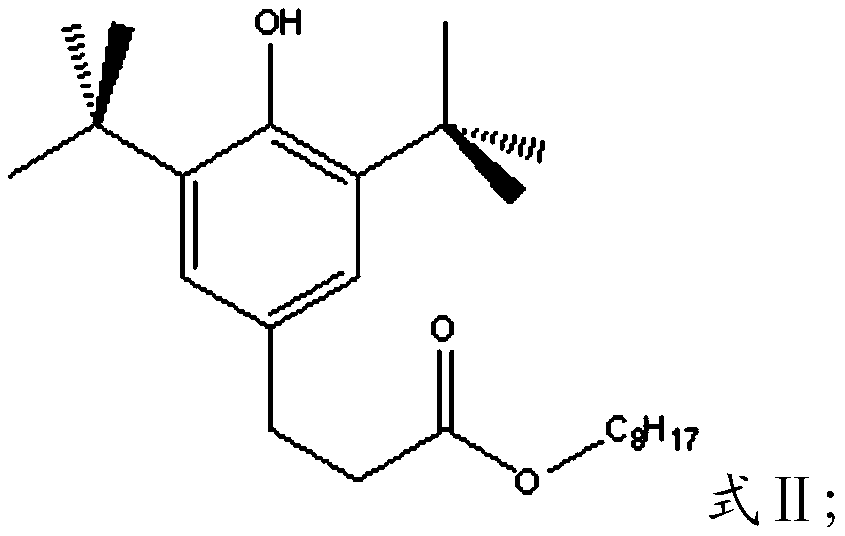

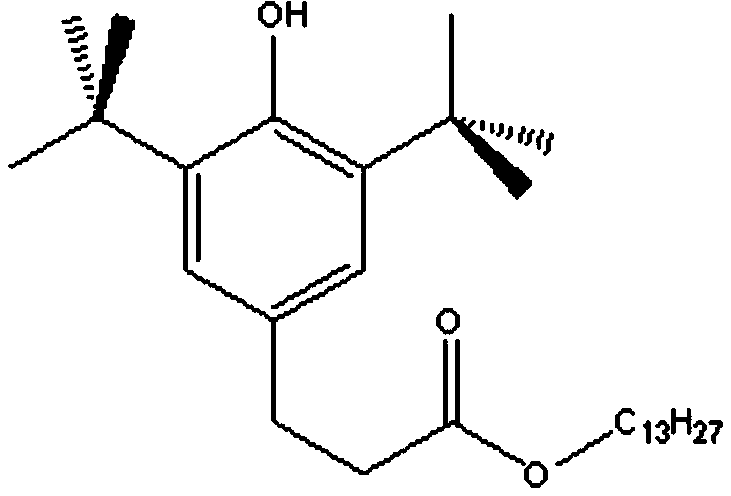

Anti-oxidation stabilizer composition and modified cis-polybutadiene

An anti-oxidative stabilizer, butadiene rubber technology, applied in the rubber field, can solve the problem of less new stabilizer and its composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0049] Take 1500ml of glue solution and place them in different 2L large beakers, add stabilizers of different components shown in Table 1 to the corresponding large beakers according to the amount of 0.3% to 0.6% of the dry glue mass, and put the glue solution in the large beaker. Put the beaker into a 60°C constant temperature water bath, stir evenly at a constant temperature, pour the glue with the stabilizer into the glue pot respectively, open the steam valve to let steam into the glue pot to boil the glue, boil the glue for about 15 minutes, take it out The circle-shaped white butadiene rubber solid is dried on a double-roll mill at 100°C to obtain raw rubber samples with different stabilizer formulations, that is, modified butadiene rubber. The physical and chemical properties of the samples before aging are tested, and then the samples are placed Carry out aging test at 105 ℃, take samples every two days to test the physical and chemical properties of the sample, test M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com