Anticorrosive paint containing graphene oxide scales, and preparation method thereof

A technology of anti-corrosion coatings and graphene, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of large dosage and low modification efficiency, achieve high bonding strength, good permeability resistance, and improve Effect of Mechanical Properties and Construction Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

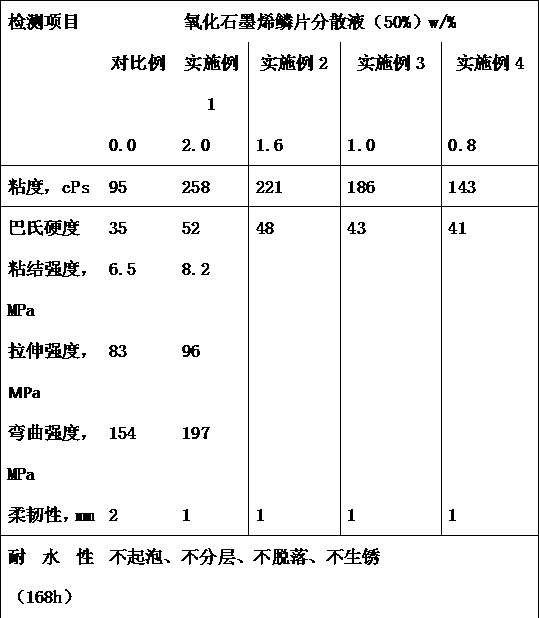

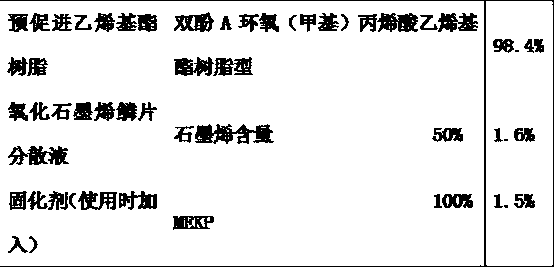

[0027] A graphene oxide flake anti-corrosion coating provided in this embodiment, its weight percentage composition is shown in Table 1.

[0028] In the present embodiment, the weight percentages of the above-mentioned components are as shown in Table 1:

[0029]

[0030] Preparation method: First, add 98 parts of the measured pre-accelerated vinyl ester resin into the high-speed disperser, then add 2 parts of the prepared graphene oxide flake dispersion, and stir at 1200-1500rpm for 1-1.5h to obtain a uniform Dispersed graphene oxide flake anticorrosion coatings. When using, just add 1-3% of curing agent (according to the weight of resin), and stir evenly.

Embodiment 2

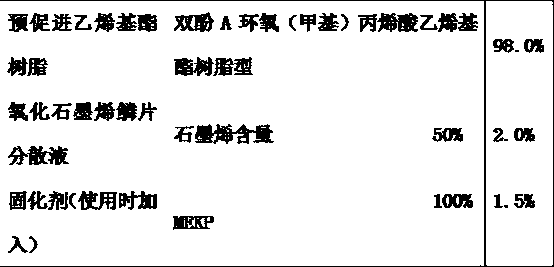

[0032] A graphene oxide flake anti-corrosion coating provided in this embodiment, its weight percentage composition is shown in Table 2.

[0033] In the present embodiment, the weight percent of above-mentioned each component is as shown in table 2:

[0034]

[0035] Preparation method: First, add 98 parts of the measured pre-accelerated vinyl ester resin into the high-speed disperser, then add 1.6 parts of the prepared graphene oxide flake dispersion, and stir at 1200-1500rpm for 1-1.5h to obtain a uniform Dispersed graphene oxide flake anticorrosion coatings. When using, just add 1-3% of curing agent (according to the weight of resin), and stir evenly.

Embodiment 3

[0037] A graphene oxide flake anti-corrosion coating provided in this embodiment, its weight percentage composition is shown in Table 3.

[0038] In the present embodiment, the weight percent of above-mentioned each component is as shown in table 3:

[0039]

[0040] Preparation method: First, add 99 parts of the measured pre-accelerated vinyl ester resin into the high-speed disperser, then add 1 part of the prepared graphene oxide flake dispersion, and stir at 1200-1500rpm for 1-1.5h to obtain a uniform Dispersed graphene oxide flake anticorrosion coatings. When using, just add 1-3% of curing agent (according to the weight of resin), and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com