Coordinated high-temperature-resistant polyamide material containing star-shaped crosslinking and preparation method of coordinated high-temperature-resistant polyamide material

A polyamide, high temperature resistant technology, applied in the field of polymer materials, can solve the problems of inability to meet, process, high glass transition and melting temperature, and achieve the effects of convenient operation, simple preparation process and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Experimental steps

[0030] 1. Preparation of coordination high temperature resistant polyamide materials containing "star" crosslinking

[0031] (1) Accurately weigh 1.1 parts by mass of hexamethylenediamine, 0.8 parts by mass of adipic acid, 0.8 parts by mass of terephthalic acid, 0.8 parts by mass of p-xylylenediamine, and 0.05 parts by mass of zinc acetate, and add to 1.5 parts by mass in turn In the aqueous solution, the temperature is 50°C, after adjusting the pH of the solution to 7.0, a transparent coordination salt solution is formed after heating for 1 hour;

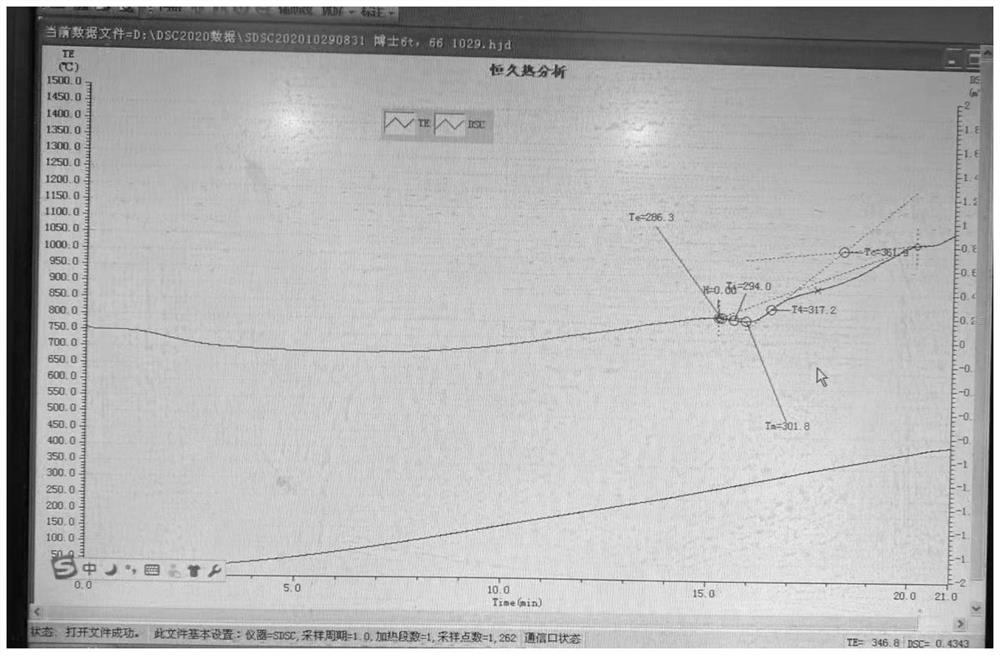

[0032] (2) Heat and mix the transparent coordination salt solution prepared in step (1) with 0.1 parts by mass (molecular weight 1000) of "star" nuclear polyacrylic acid to form colorless transparent salt solution A, and add the A solution into the polymerization kettle, Pre-polymerization at 220°C for 3 hours to form polyamide with small molecular weight; secondary pre-polymerization at 280-300°C fo...

Embodiment 2

[0039] 1. Preparation of "star" crosslinked coordination type high temperature resistant polyamide resin

[0040] (1) Accurately weigh 0.5 parts by mass of hexamethylenediamine, 0.8 parts by mass of terephthalic acid, 0.5 parts by mass of p-xylylenediamine, 1.5 parts by mass of water, and 0.05 parts by mass of zinc acetate, and add them to 1.5 parts by mass of aqueous solution in sequence , after adjusting the pH of the solution to 7.0, it was heated for 1.5 hours to form a transparent coordination salt solution.

[0041](2) Heat and mix the transparent coordination salt solution prepared in step (1) with 0.1 parts by mass (molecular weight: 1000) of "star" core polyacrylic acid-co-acrylate to form transparent solution B, and add solution B to the polymerization kettle , Pre-polymerization at 220°C for 3 hours, pre-polymerization to form polyamide with small molecular weight; secondary pre-polymerization at 280-300°C for 60 minutes; pre-polymerization at 300-335°C for 15 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com