Brake energy recovering rate test method for battery electric vehicle

A pure electric vehicle, braking energy technology, applied in the field of pure electric vehicle braking energy recovery rate test, can solve the problems of inconvenient acquisition of vehicle signals, poor calculation accuracy, difficult test, etc., to reduce safety hazards and measurement costs, Reduce workload and facilitate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

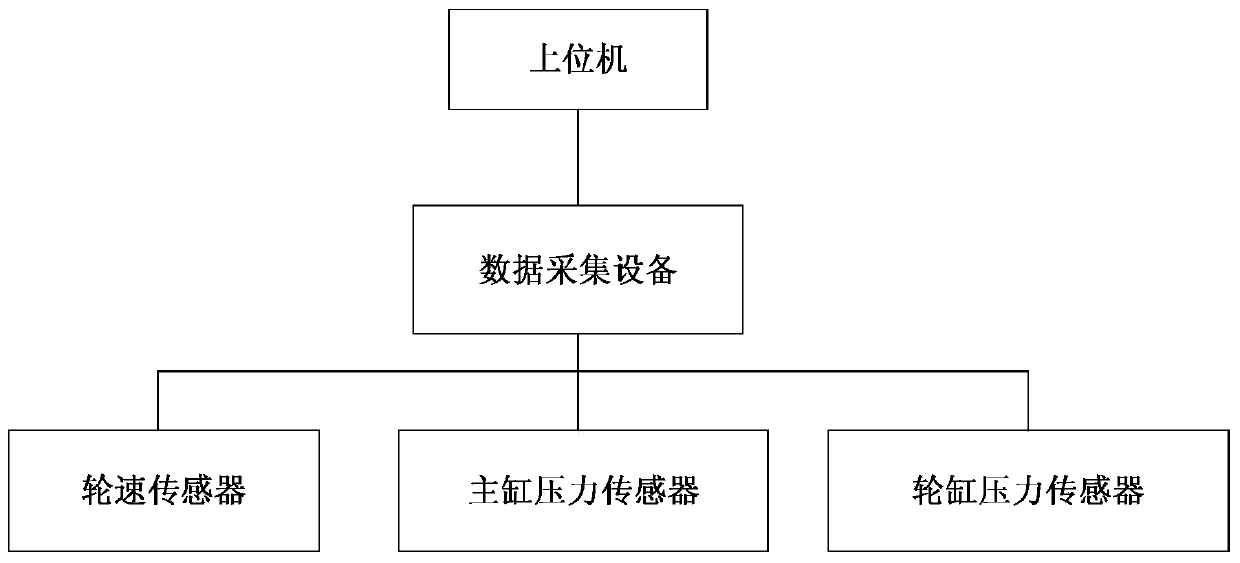

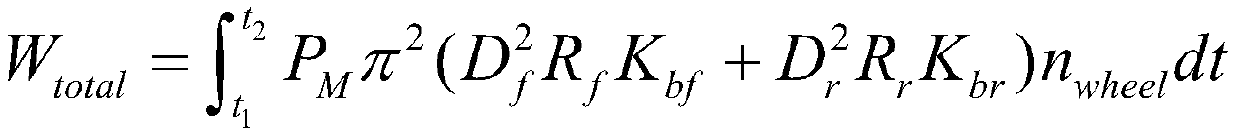

[0036] combine figure 1 , a pure electric vehicle braking energy recovery test device of the present embodiment includes a host computer, a data acquisition device, a wheel speed sensor, a master cylinder pressure sensor and a wheel cylinder pressure sensor.

[0037] The upper computer is used for fusion, monitoring, recording, and processing of various data in the experimental process; the data acquisition device is used for collecting various sensor signals; the wheel speed sensor is used for collecting wheel speed signals; the master cylinder pressure sensor It is used to collect the master cylinder pressure signal; the wheel cylinder pressure sensor is used to collect the wheel cylinder pressure signal.

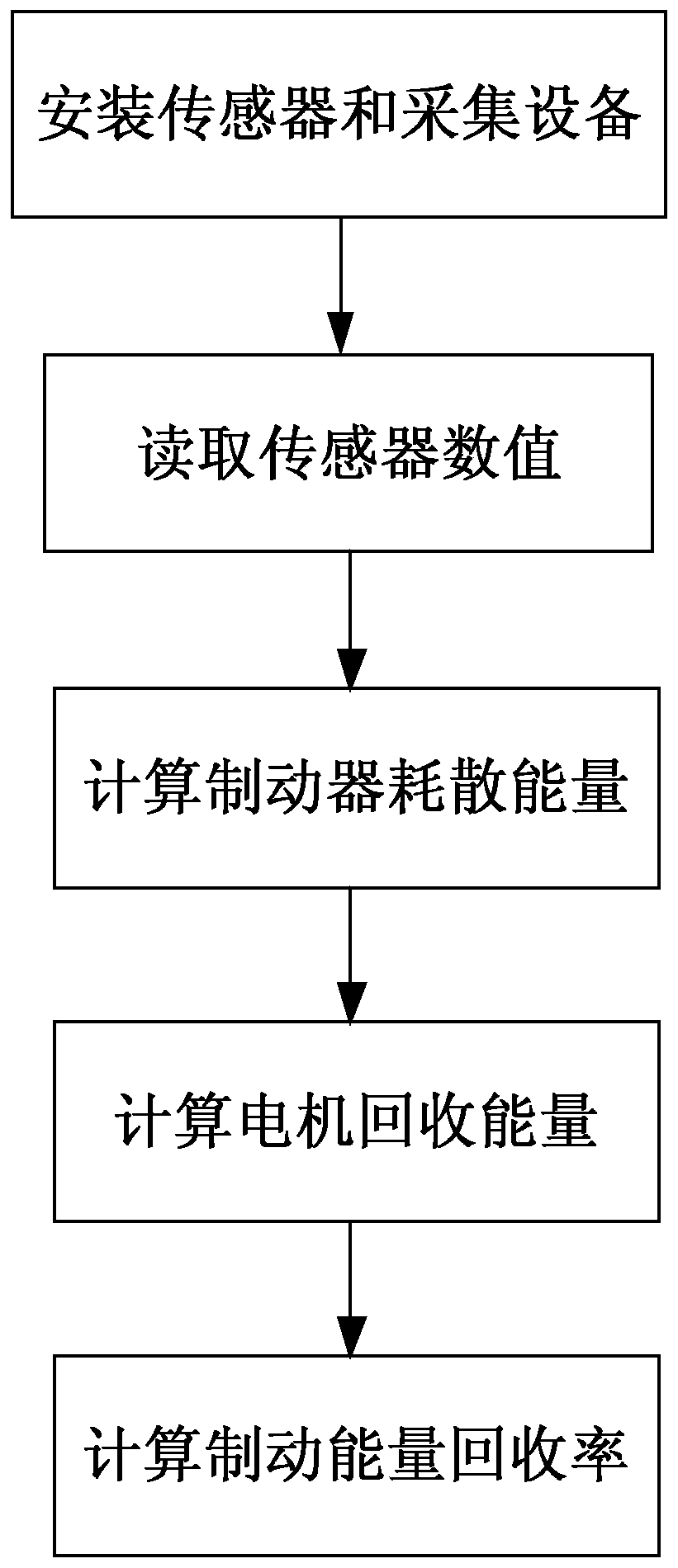

[0038] combine figure 2 , a pure electric vehicle braking energy recovery testing method of the present embodiment, the steps are:

[0039] 1) Install sensors and data acquisition equipment. Install wheel cylinder pressure sensors at the interface of the left front wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com