Method, device and system for detecting tire defects

A tire and defect technology, applied in the field of image recognition, can solve the problems of lack of universality, large differences in defect geometry, and poor robustness of detection algorithms, so as to avoid over-fitting problems, improve inspection accuracy, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

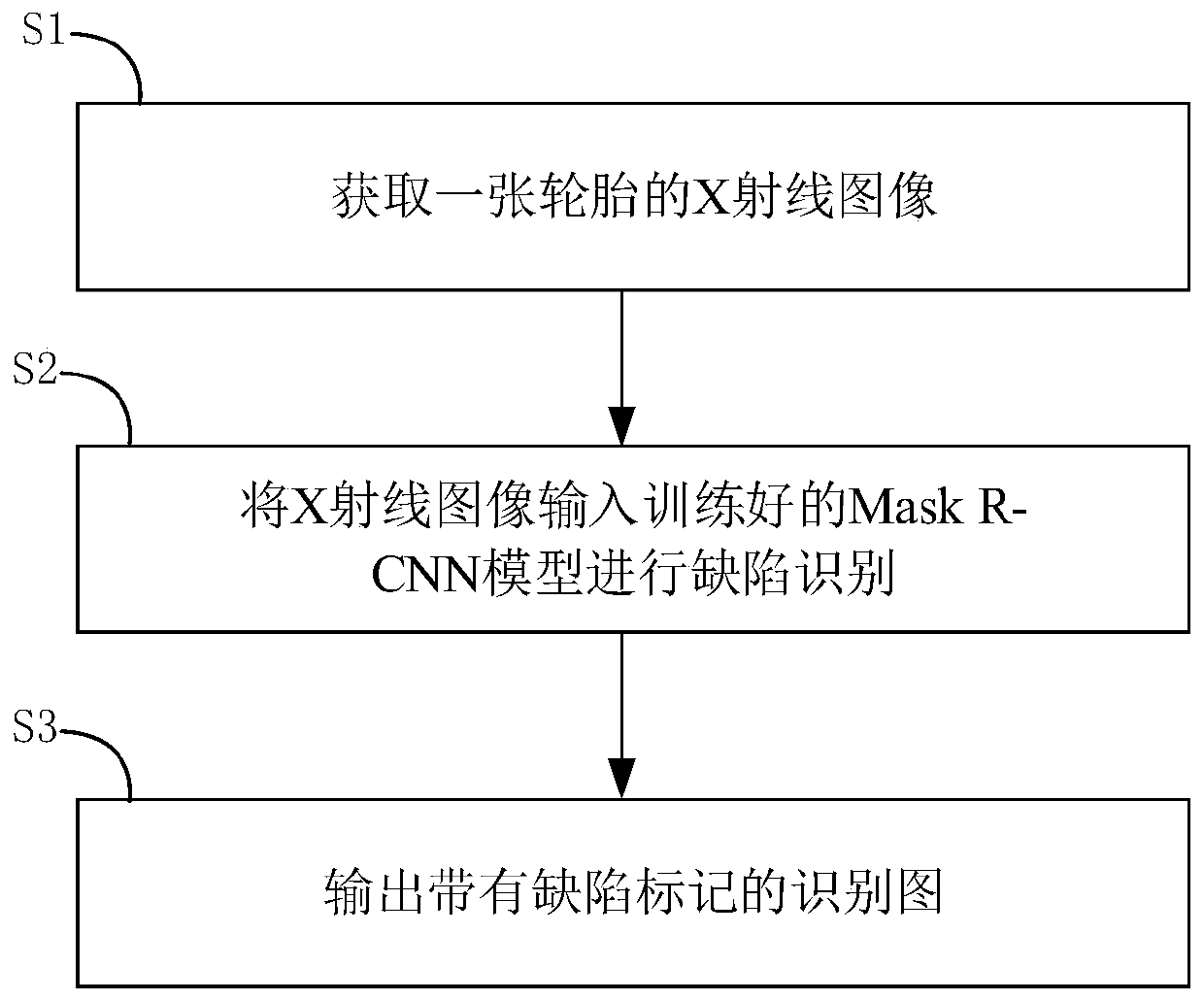

[0043] Such as figure 1 As described, the present embodiment provides a method for detecting tire defects, comprising the following steps:

[0044] Step S1, obtaining an X-ray image of a tire;

[0045] Step S2, input the X-ray image into the trained Mask R-CNN model for defect recognition;

[0046] Step S3, outputting a recognition map with defect marks.

[0047] This method can quickly and accurately detect air bubbles in the sidewall and inside the tire, open joints, splitting seams, thin threads, sundries, thin threads, steel wire bending, cord cross-lapping, cord disconnection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com