Nuclear reactor power source with heat pipes bidirectionally inserted into reactor core

A nuclear reactor and core technology, applied in the field of nuclear reactor power supply, can solve the problems of low output power, strict space restrictions, and difficult flexible deployment, etc., and achieve the effects of strong environmental adaptability, broad application prospects, and increased numbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better illustrate the present invention, the working principle of the present invention will now be described in conjunction with the accompanying drawings.

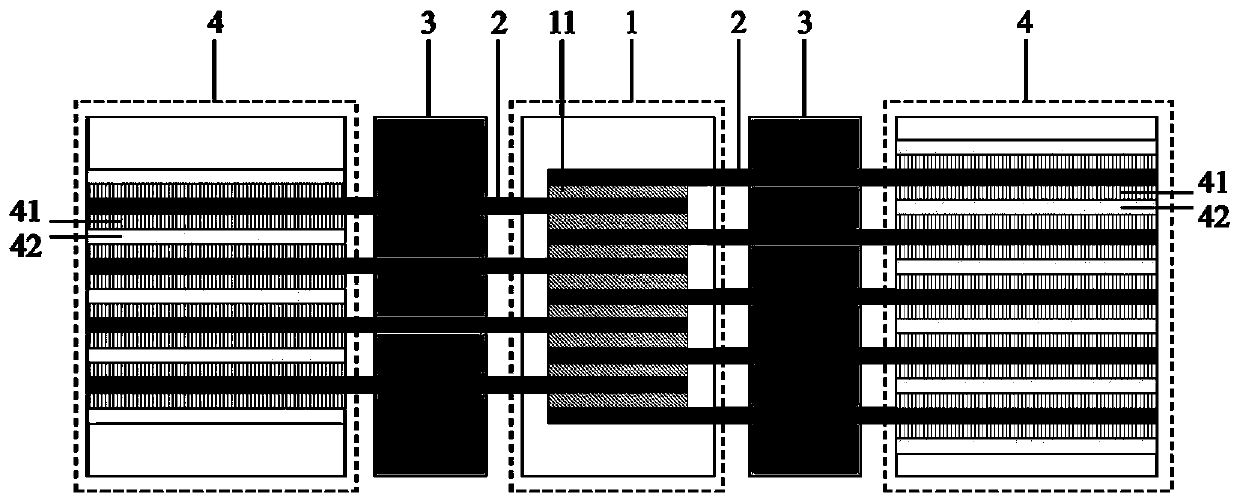

[0017] Such as figure 1 As shown, the layout diagram of the nuclear reactor power supply in which the heat pipes of the present invention are bidirectionally inserted into the core includes a core 1, two sets of heat pipes 2, shielding bodies 3 and two sets of power generation components 4, and one end of the two sets of heat pipes 2 is connected from the core 1 respectively. Both sides are inserted into the core 1, and the other end is respectively inserted into the power generation component 4. The shield 3 is arranged between the core 1 and the power generation component 4. The heat pipe 2 passes through the shield 3. The shield 3 protects the power generation component 4 from Radiation damage to core 1. The power generation component 4 adopts the silent temperature difference thermoelectric conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com