Composite emulsion stabilizer and coconut juice beverage

A compound emulsification and stabilizer technology, which is applied in the direction of food ingredients as emulsifiers, food ingredients as turbidity agents, food ingredients as taste improvers, etc., can solve the problems of fat coagulation, precipitation, and lower layer precipitation in coconut milk beverages, and achieve no Effect of astringency and graininess, good sensory quality, strong coconut flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

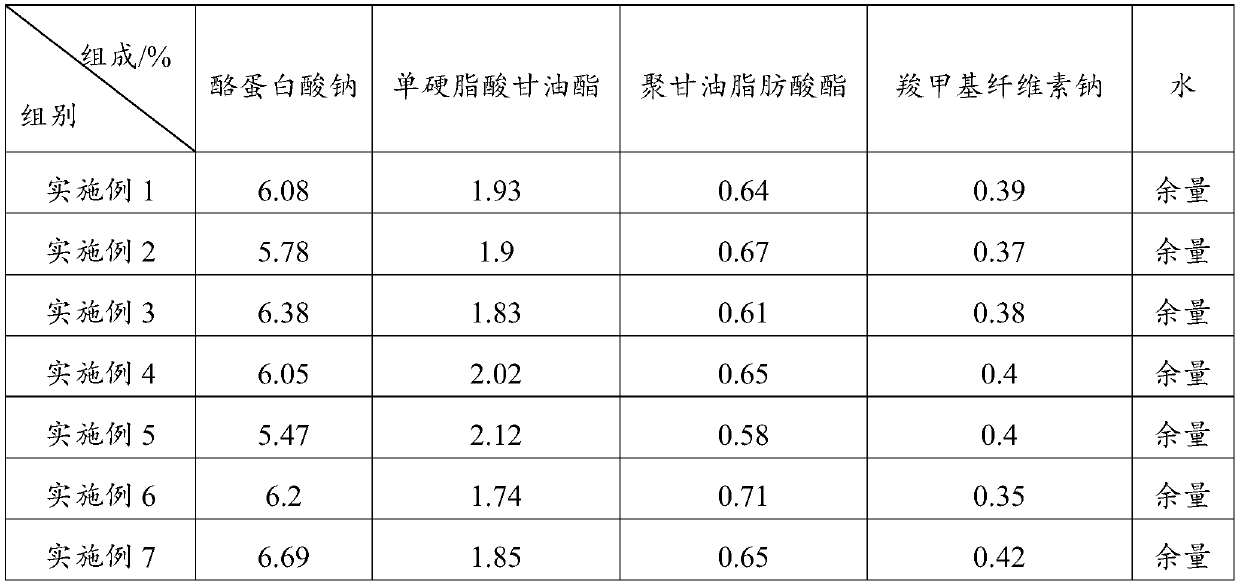

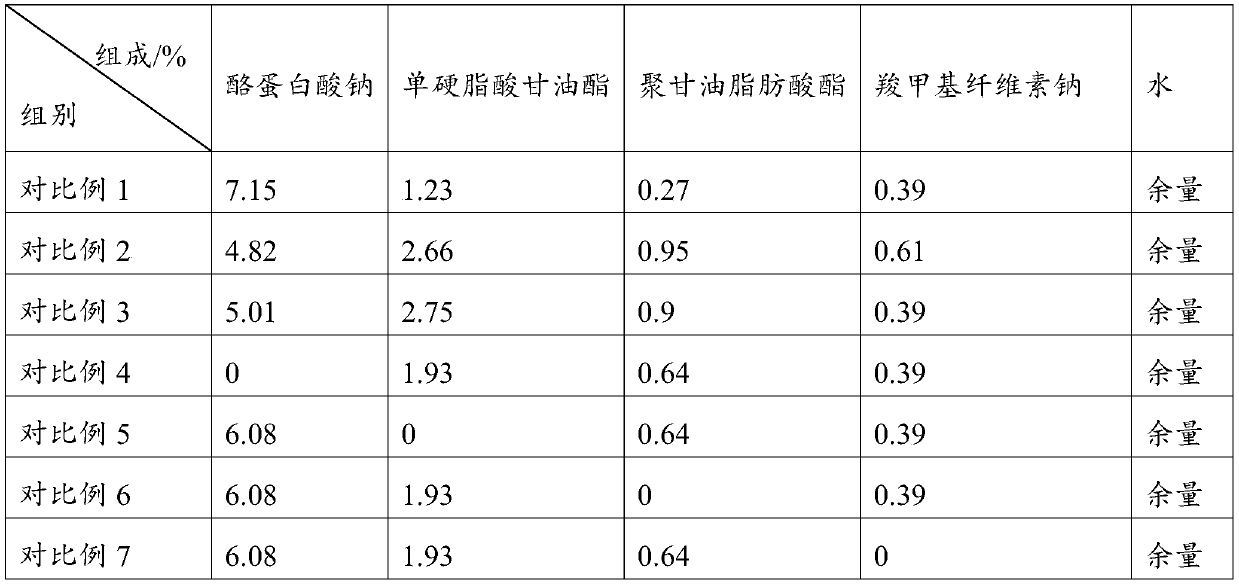

[0027] See Table 1 for the formula of the compound emulsion stabilizer described in Examples 1-7.

[0028] The preparation method of the composite emulsion stabilizer described in embodiment 1~7 comprises the following steps:

[0029] 1. Weigh each component of the compound emulsion stabilizer according to the ratio;

[0030] 2. Mix sodium carboxymethyl cellulose, glyceryl monostearate, and sodium caseinate and stir evenly to obtain premix A; under stirring, slowly add polyglyceryl fatty acid ester to hot water at 70°C to Fully dissolve, then add premix A, continue to stir until uniform, and filter through 100 mesh to obtain a composite emulsification stabilizer.

[0031] The formula of the compound emulsion stabilizer described in table 1 embodiment 1~7

[0032]

Embodiment 8~12、 comparative example 8、9

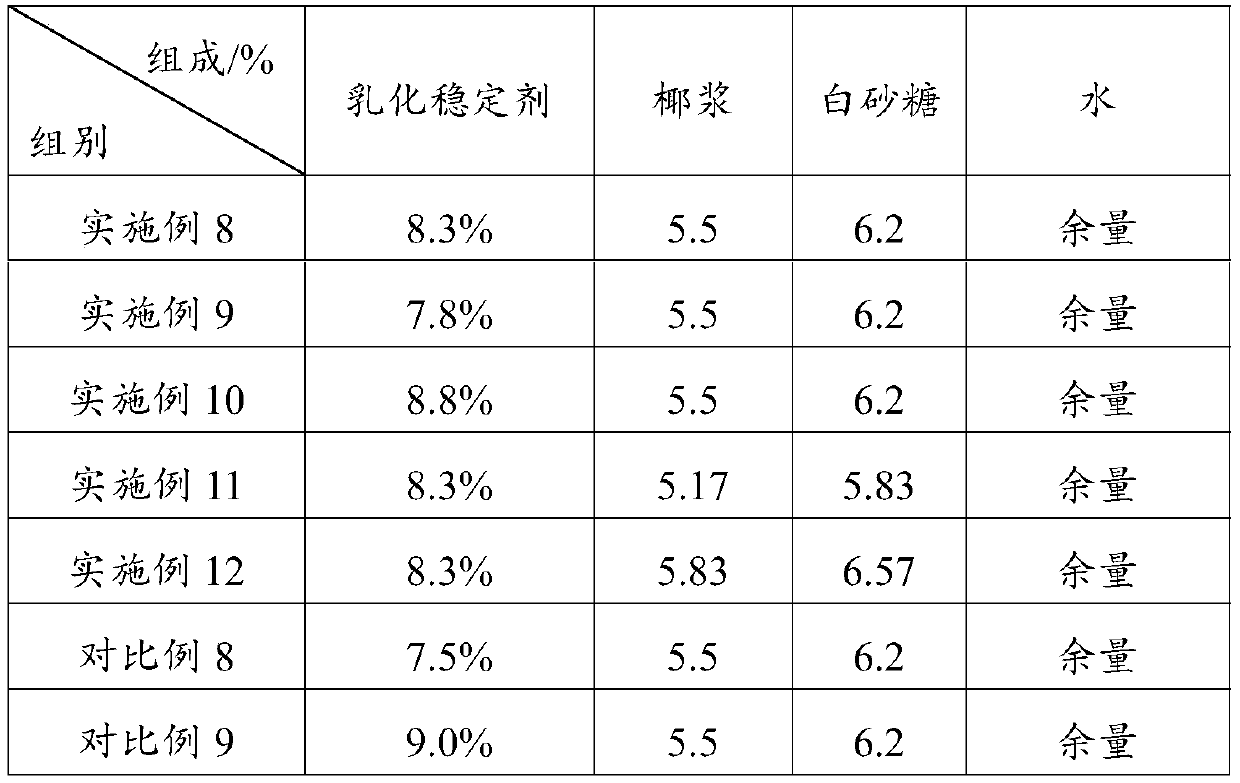

[0038] The emulsion stabilizer described in Example 1 is prepared coconut milk beverage according to the prescription of embodiment 8~12, comparative example 8,9, and the formula of embodiment 8~12, comparative example 8,9 described coconut milk beverage is shown in Table 3 .

[0039] Embodiment 8~12, the preparation method of coconut juice beverage described in comparative example 8,9 comprises the following steps:

[0040] 1. Acceptance of raw and auxiliary materials: After the coconut milk, white sugar, and emulsification stabilizer pass the inspection, weigh the required amount according to the formula;

[0041] 2. Coconut milk dissolution and hydration: Add 50°C RO water into the auxiliary material tank, quickly add coconut milk under stirring, continue to stir for 10 minutes until completely dissolved, filter through 100 mesh, heat to 75±5°C, pump Put it into the hydration barrel (75±5℃, 30min), put it into the temporary storage tank after hydration;

[0042] 3. Emulsi...

Embodiment 13

[0051] The emulsification stabilizers described in Examples 1 to 7 and Comparative Examples 1 to 7 were prepared into coconut milk drinks according to the formula of 6.2% white granulated sugar, 5.5% coconut milk, and 8.3% compound emulsification stabilizer, which were used as test groups 1 to 7 and Matched group 1~7, the coconut milk drink described in embodiment 8~12, comparative example 8,9 is respectively as test group 8~12, matched group 8,9, as shown in table 4; Investigate test group 1~12 and The stability of the coconut milk drinks described in the control group 1 to 9 at different storage temperatures (-18°C, 4°C, normal temperature (25°C), and 37°C), the investigation indicators are: fat floating height (unit: mm), lower layer Precipitation thickness (unit: mm), centrifugal sedimentation rate (%), pH value, comprehensive sensory evaluation.

[0052] Measuring method of fat floating height: After the sample to be tested stands still (the standing time is not less than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com