Electric toothbrush head

An electric toothbrush and brush head technology, which is applied in the field of daily necessities, can solve the problems of difficulty in ensuring the tight fit between the transmission shaft and the brush head, complex transmission structure, and low production efficiency, and achieve good fixing effect, convenient disassembly and replacement, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

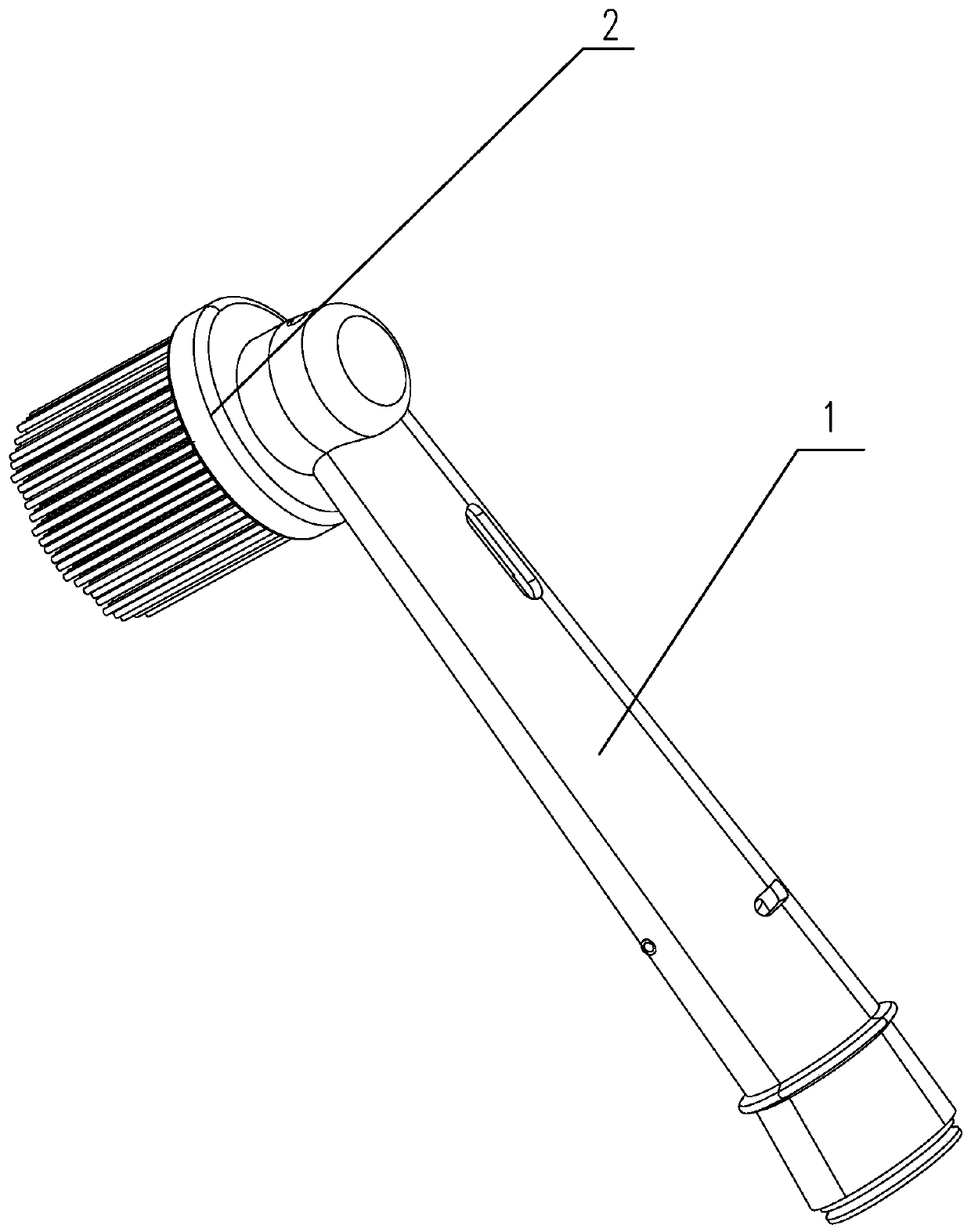

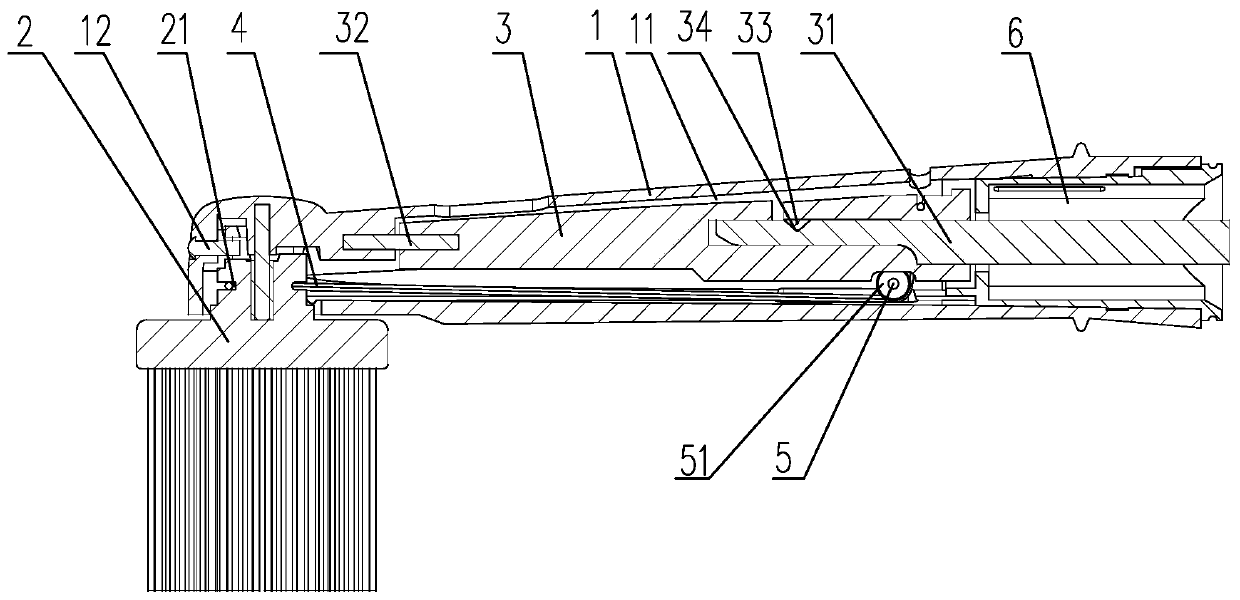

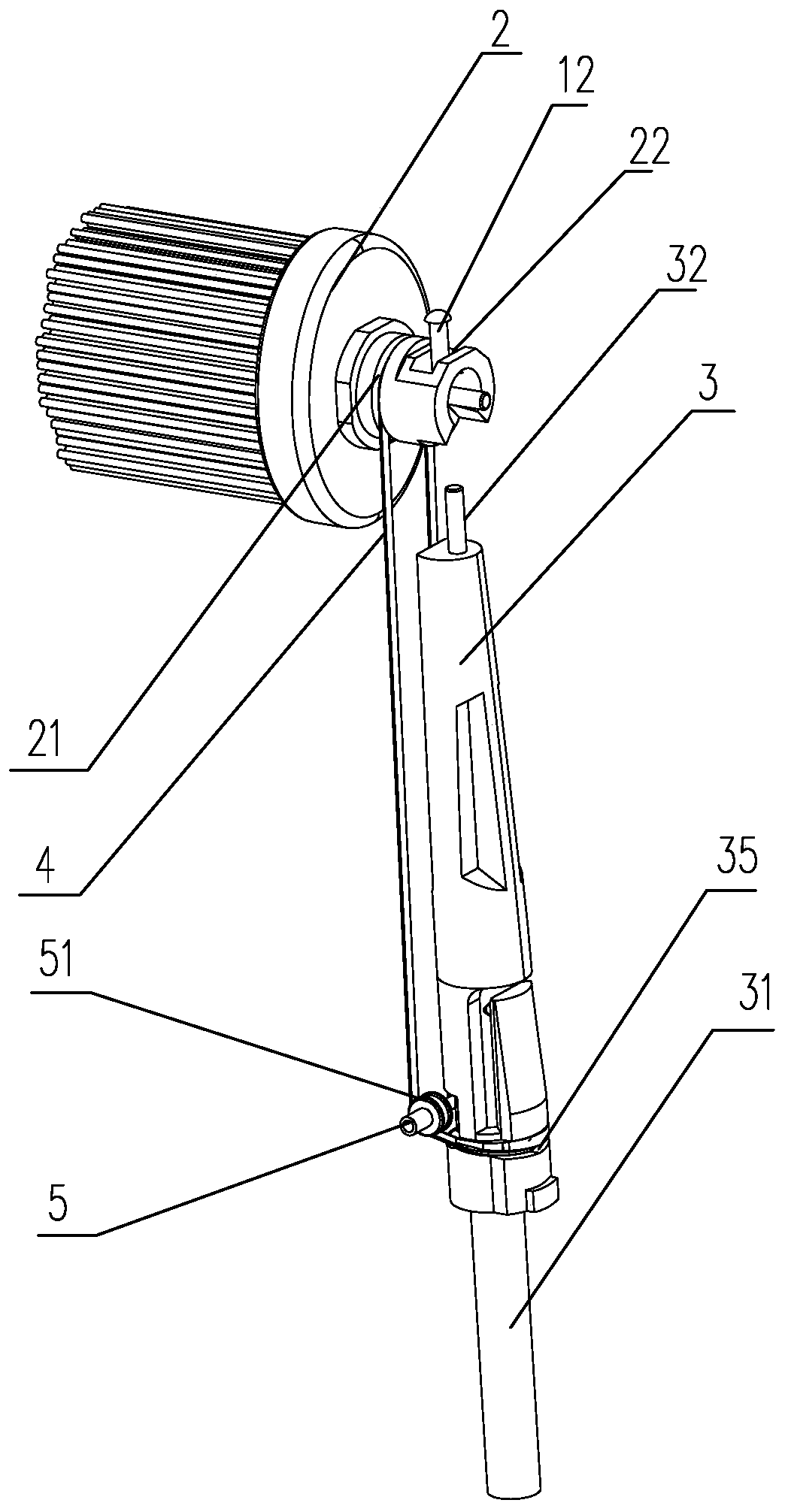

[0023] Depend on figure 1 , figure 2 and image 3 It can be seen that a brush head for an electric toothbrush is disclosed, including a brush handle 1 and a brush plate 2, the brush handle 1 is hollowly provided with an accommodating cavity 11, one end of the brush handle 1 is provided with a rotating groove, and the other end is provided with a There is a transmission slot, and the rotation slot and the transmission slot are set through the accommodation cavity 11. The brush plate 2 is rotatably set on the rotation slot, and the accommodating cavity 11 is rotatably provided with a driving seat 3. The drive base 3 is provided with a drive rod 31 for connecting with the motor to drive and reciprocate in the accommodation cavity 11, and a reversing member is also rotated in the accommodation cavity 11, and a traction rod 31 is arranged in the accommodation cavity 11. Belt 4, one end of the traction belt 4 is fixedly connected to the outer peripheral wall of the brush plate 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com