Guide rail welding production line

A welding production line and guide rail technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems affecting the safety and reliability of buildings, the lack of guide rail setting and positioning methods, and the inability to guarantee the straightness of guide rails. Achieve the effects of improving production efficiency and finished product quality, improving welding accuracy and assembly efficiency, and improving welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

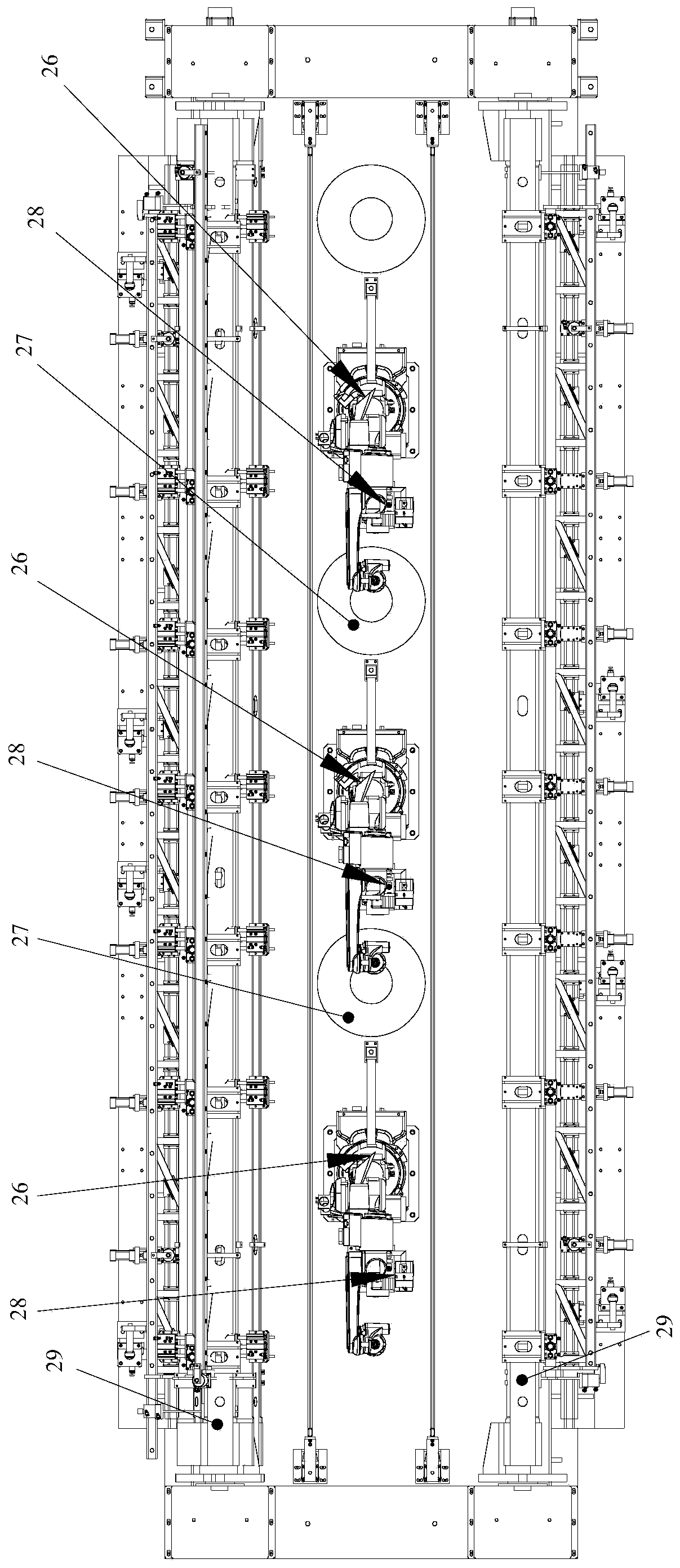

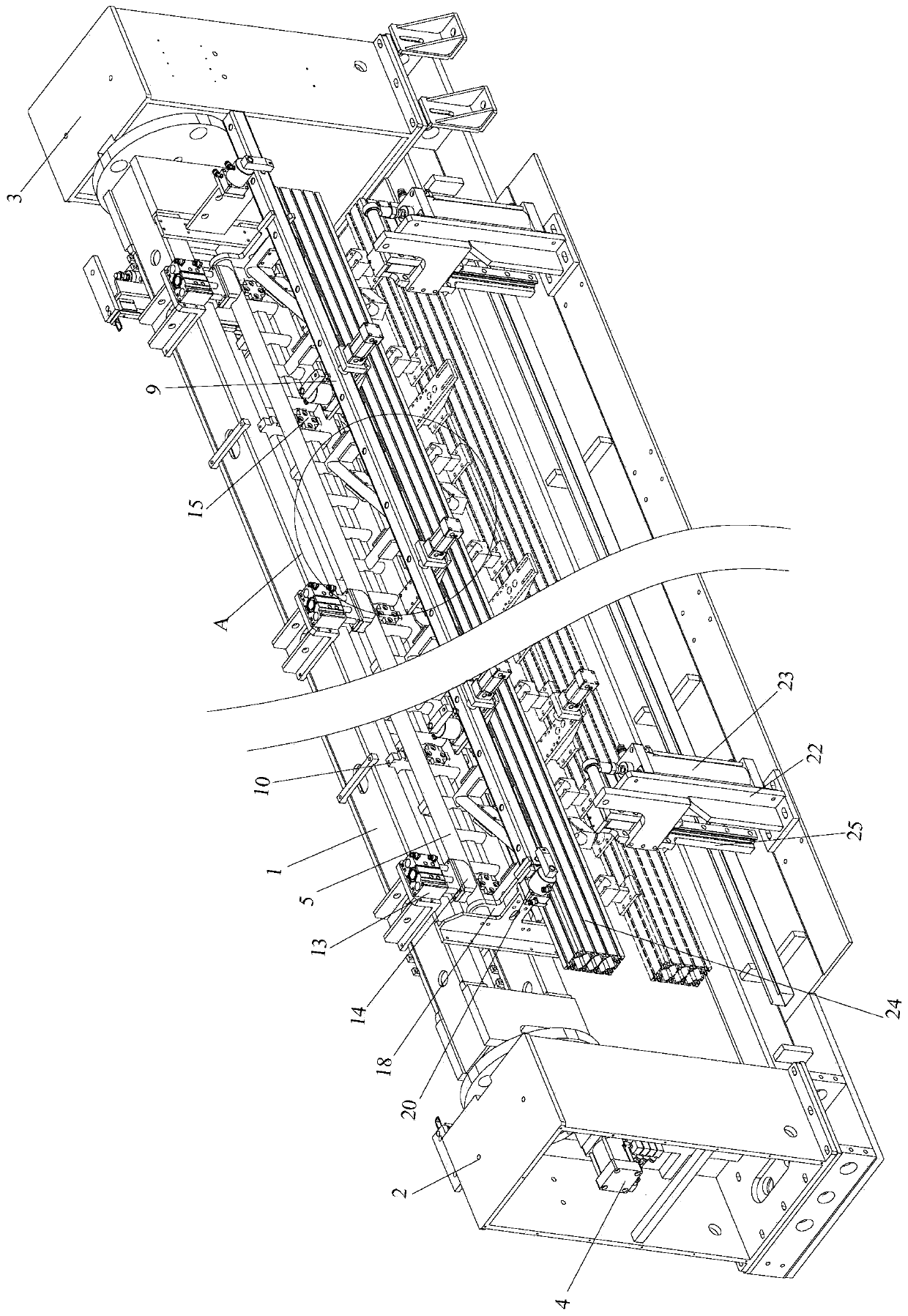

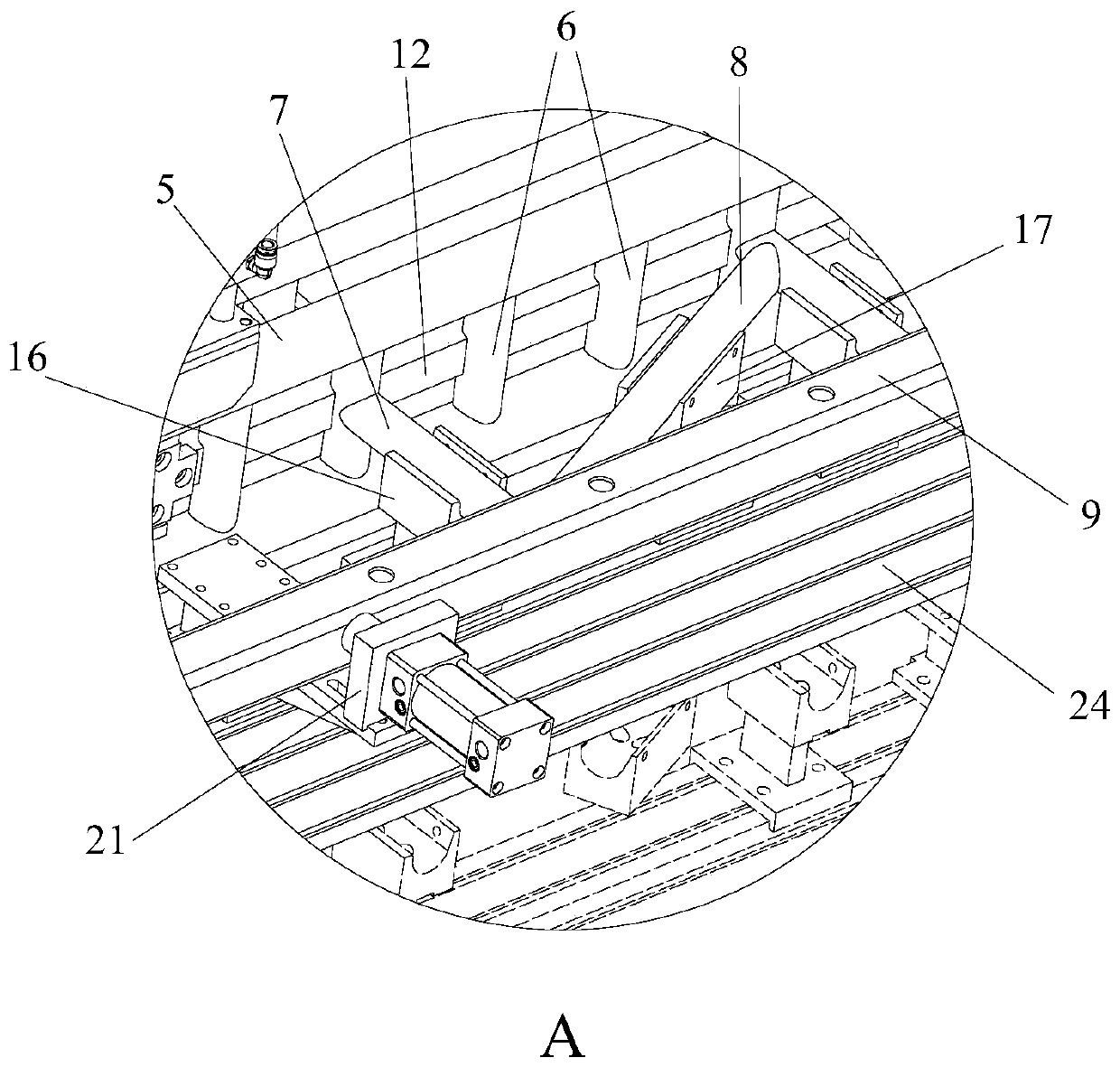

[0053] Such as Figure 1 to Figure 7 Shown, guide rail welding production line of the present invention comprises:

[0054] Two guide rail turning devices 29 for positioning the guide rail and providing a welding platform;

[0055] and three welding robots 26 for welding the rails;

[0056] Two guide rail turning devices 29 are mirrored and arranged on both sides of the welding robot 26, and three welding robots 26 are arranged in the middle of the two guide rail turning devices 29 and arranged along the length direction of the guide rail turning devices 29, so that the two sides are positioned on the guide rail turning devices The guide rail on 29 is welded;

[0057] In addition, in order to facilitate the work of the welding robots 26 , a torch cleaner 28 and a wire storage barrel 27 are arranged on the side of each welding robot 26 .

[0058] Among them, each rail flipping device includes:

[0059] Working platform 1 for providing welding platform;

[0060] The active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com