Device and method for synchronous treatment of ship waste gas desulfurization, denitrification waste liquid and ship domestic sewage

A technology for waste gas desulfurization and domestic sewage, applied in biological treatment devices, biological water/sewage treatment, gaseous effluent wastewater treatment, etc., can solve problems such as increased operating costs, reduce operating costs, promote rapid growth, and achieve comprehensive management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

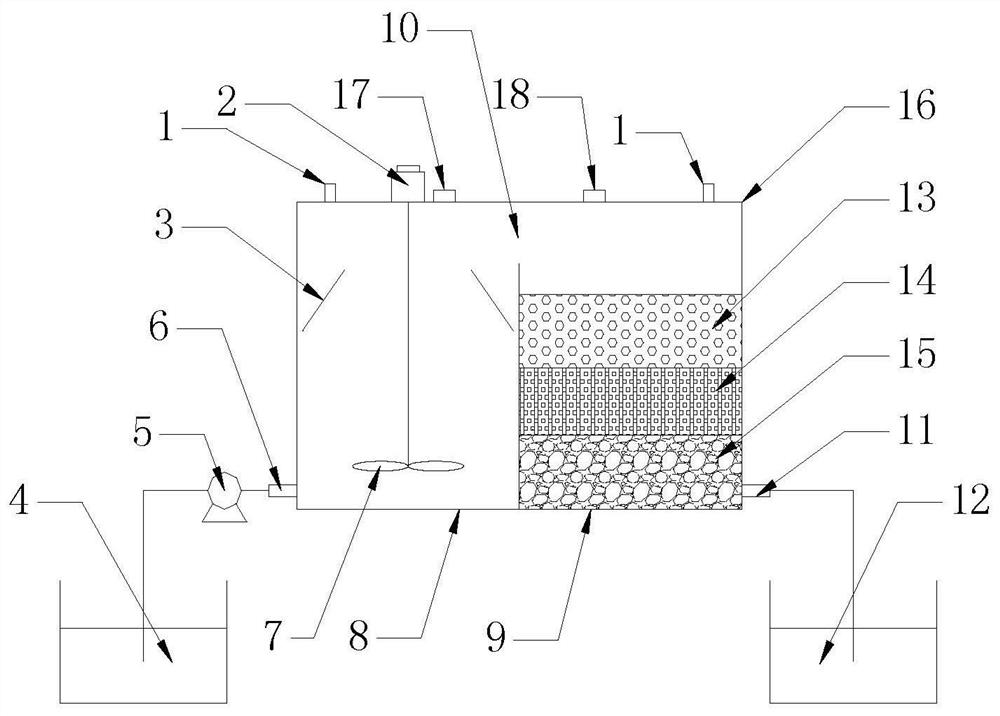

[0049] This embodiment provides a device and method for synchronously treating ship waste gas desulfurization, denitrification waste liquid and ship domestic sewage. The synchronous processing device includes a reactor shell 16, the bottom of the reactor shell 16 is provided with a liquid inlet 6 and a liquid outlet 11, and the reactor shell 16 is provided with a suspension area 8 and a packing area 9, and the suspension area 8 and the packing area 9 have the same volume, the upper part of the suspension area 8 is provided with an overflow port 10 to communicate with the packing area 9, and the vertical height of the overflow port 10 is 1.0cm; The lower surface of the reactor is 1.0 cm, the liquid outlet 11 is connected to the packing area 9, and the central axis of the liquid outlet 11 is 1.0 cm away from the lower surface of the reactor; the central axis of the liquid outlet 11 of the packing area 9 is 1.0 cm away from the lower surface of the reactor. A stirrer is provided ...

Embodiment 2

[0056] This embodiment provides a device and method for synchronously treating ship waste gas desulfurization, denitrification waste liquid and ship domestic sewage. The synchronous processing device includes a reactor shell 16, the bottom of the reactor shell 16 is provided with a liquid inlet 6 and a liquid outlet 11, the reactor shell 16 is provided with a suspension area 8 and a packing area 9, and the upper part of the suspension area 8 is provided with The overflow port 10 is connected with the filling area 9, and the vertical height of the overflow port 10 is 1.0 cm; the liquid inlet 6 is connected with the suspension area 8, and the central axis of the liquid inlet 6 is 1.0 cm away from the lower surface of the reactor, and the liquid outlet 11 It communicates with the filling area 9, and the central axis of the liquid outlet 11 is 2.0 cm away from the lower surface of the reactor; the central axis of the liquid outlet 11 of the packing area 9 is 2.0 cm away from the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com