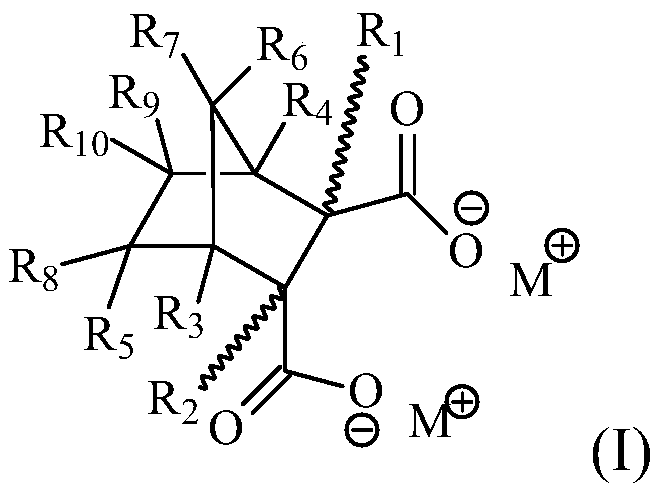

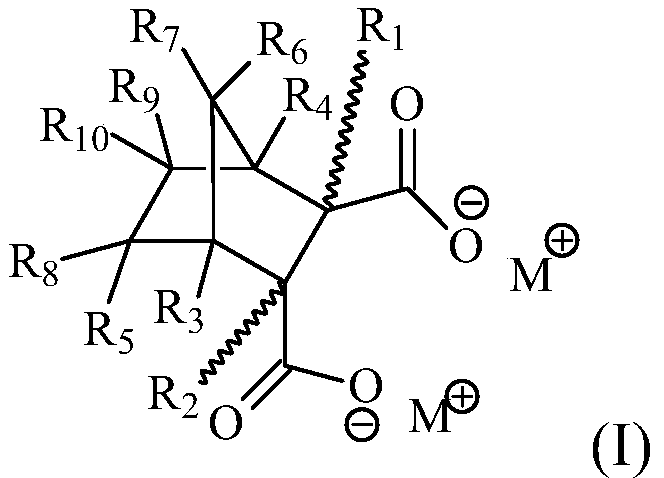

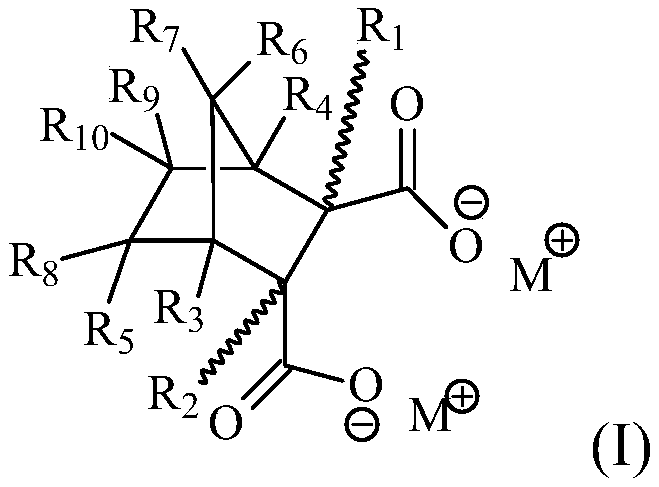

Nucleating agent and preparing method and application thereof

A technology of nucleating agent and acetal, which is applied in the fields of nucleating agent and its preparation and application, can solve the problems of unfavorable comprehensive performance and reduce the nucleation efficiency of polyolefin products, and achieve improvement of flexural modulus, transparency and fog reduction degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the nucleating agent of the present invention comprises the steps of: dispersing bicyclic carboxylate A, benzoate B and dibenzylidene alditol acetal C in water, fully mixing, then drying and pulverizing to obtain the nucleating agent agent. The amount of water used is not particularly limited. Drying and pulverizing conditions are conventional conditions, which will not be repeated here.

[0037] In addition, the present invention also provides the use of the above-mentioned nucleating agent in improving the flexural modulus and transparency of thermoplastic resins. Thermoplastic resin means a polymeric material that melts when heated but remains solid when cooled; including but not limited to polyolefins, polyamides, polyurethanes or polyesters. The thermoplastic resin is preferably polyolefin, so that the effect of the nucleating agent can be maximized. Therefore, the present invention also provides the use of the above-mentioned nucleatin...

Embodiment 1

[0039] Disperse bicyclo[2.2.1]heptane-2,3-dicarboxylate disodium salt, sodium benzoate and 1,3:2,4-bis(p-methylbenzylidene)sorbitol in water and mix well , then dried and pulverized to obtain the nucleating agent. See Table 1 for specific ratios.

[0040] Table 1

[0041]

experiment example

[0047] The nucleating agents of Example 1 and Comparative Examples 1 to 3 were added to the polypropylene resin. Based on the weight of polypropylene, the dosage of nucleating agent is 0.56‰, the dosage of antioxidant 1010 is 0.5‰, the dosage of antioxidant 168 is 0.5‰, and the dosage of calcium stearate is 0.5‰.

[0048] The specific process conditions are:

[0049] The temperature of each part of the extruder: 1st stage, 190°C; 2nd stage, 199°C; 3rd stage, 212°C; 4th stage, 222°C; 5th stage, 221°C; 6th stage, 222°C.

[0050] Melt temperature: 235°C;

[0051] Screw speed: 30Hz;

[0052] Feeding speed: 40rpm

[0053] Head pressure: 1.1-1.2MPa.

[0054] The mixture was melted and granulated, and the properties of the modified polypropylene resin were measured, see Table 3 for details. Wherein, the flexural modulus is measured by GB / T 9341-2008 or ISO178:2001. Haze is measured by GB / T 2410-2008.

[0055] table 3

[0056] serial number Flexural modulus / MPa H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com