Preparation method of low-formaldehyde easy-care resin

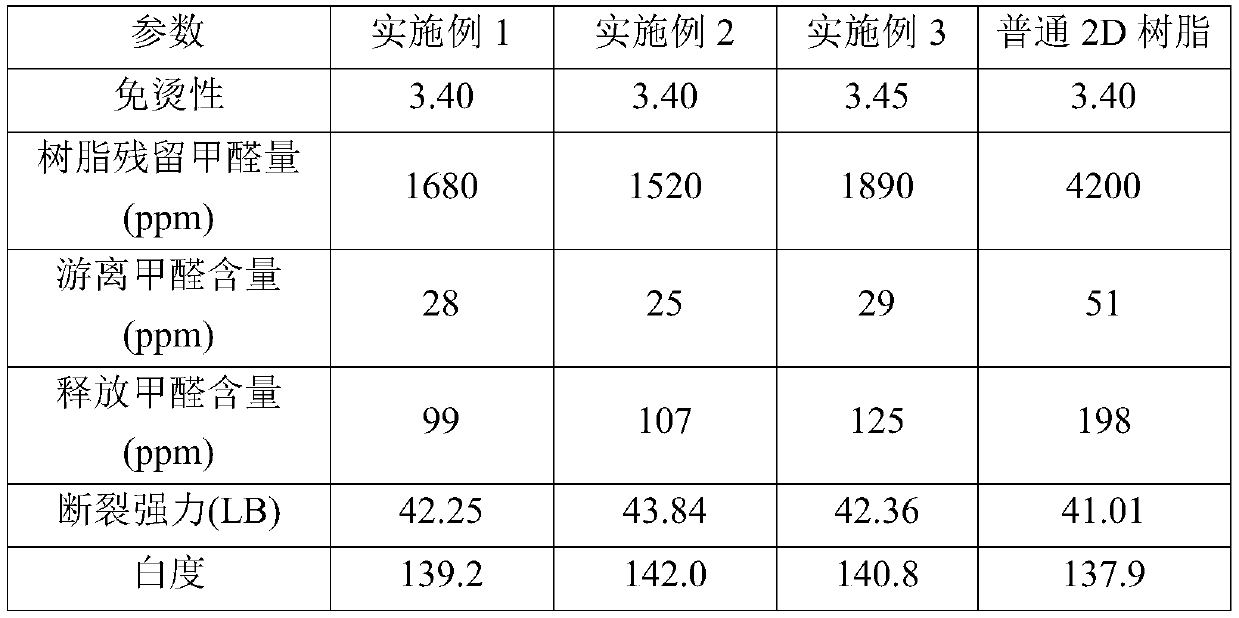

A non-iron resin and low-formaldehyde technology, which is applied in the direction of plant fibers, can solve the problems of no non-iron performance, low reactivity, and loss of multi-strength, and achieves low free formaldehyde content and formaldehyde emission. The preparation method is simple, The effect of high whiteness values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of Dimethylolethylene Urea Solution

[0050] Add 600.0 g of 37% formaldehyde solution to a 1L four-neck glass flask equipped with a mechanical stirrer, a condenser, and a thermometer. Start stirring, add 242.7g of urea until the urea is completely dissolved, slowly raise the temperature to 40°C, stir and keep warm for 4 hours, the free formaldehyde content is 1.32%. The product was transferred to a vacuum distillation device, the vacuum was turned on to 300mbar, and the solution temperature was maintained at 40°C for vacuum distillation to distill 91g of fractions. The remaining product was transferred to a synthesis reaction device, the temperature was raised to 50° C., 30.2 g of urea was added, and the reaction was continued for 2 hours. The measured free formaldehyde content was 0.47%. Transfer the product to a vacuum distillation device, turn on the vacuum to 750mbar, maintain the solution temperature at 50°C for vacuum distillation, and distill 48g of ...

Embodiment 2

[0056] Preparation of Dimethylolethylene Urea Solution

[0057] Add 550.0 g of 37% formaldehyde solution to a 1L four-necked glass flask equipped with a mechanical stirrer, a condenser, and a thermometer. Start the stirring, add 216.3g of urea until the urea is completely dissolved, slowly raise the temperature to 50°C, stir and keep warm for 3 hours, the free formaldehyde content is 1.43%. Transfer the product to a vacuum distillation device, turn on the vacuum to 300mbar, maintain the solution temperature at 40°C for vacuum distillation, and distill 82.5g of fractions. The remaining product was transferred to the synthesis reaction device, the temperature was adjusted to 50° C., 42.1 g of urea was added, and the reaction was continued for 2.5 hours. The measured free formaldehyde content was 0.41%. Transfer the product to a vacuum distillation device, turn on the vacuum to 750mbar, maintain the solution temperature at 50°C for vacuum distillation, and distill 41.25g of frac...

Embodiment 3

[0063] Preparation of Dimethylolethylene Urea Solution

[0064] Add 650.0 g of 37% formaldehyde solution to a 1L four-necked glass flask equipped with a mechanical stirrer, a condenser, and a thermometer. Start stirring, add 245.2g of urea until the urea is completely dissolved, slowly raise the temperature to 60°C, stir and keep warm for 4 hours, the free formaldehyde content is 1.21%. Transfer the product to a vacuum distillation device, turn on the vacuum to 300mbar, maintain the solution temperature at 40°C for vacuum distillation, and distill 90.8g of fractions. The remaining product was transferred to a synthesis reaction device, the temperature was adjusted to 50° C., 39.2 g of urea was added, and the reaction was continued for 3 hours. The measured free formaldehyde content was 0.48%. The product was transferred to a vacuum distillation device, the vacuum was turned on to 750mbar, the solution temperature was maintained at 50°C for vacuum distillation, and 47.9g of fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com