A Metallographic Corrosion Method for Rapidly Displaying Grain Boundaries of Special Steel

A metallographic corrosion and special steel technology, which is applied in the preparation of test samples and other directions, can solve the problems of safety, long detection period and complicated procedures of corrosive agents, and achieve the effects of short corrosion time, convenient operation and simple corrosion steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A metallographic corrosion method for rapidly displaying special steel grain boundaries, comprising the following steps:

[0024] Step 1, prepare dinitrophenol corrosion agent;

[0025] Step 2. Roughly grind the surface of the special steel sample to remove the rust layer on the surface. The coarsely ground sample is finely ground on sandpaper; the finely ground sample surface is polished to obtain a bright and scratch-free surface. sample surface;

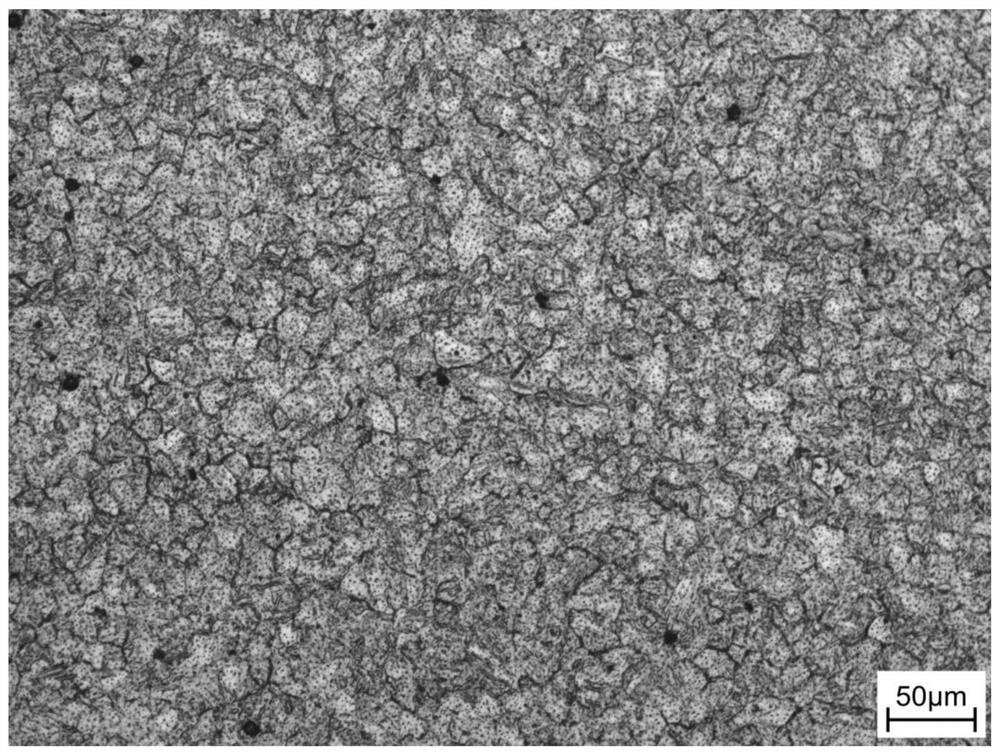

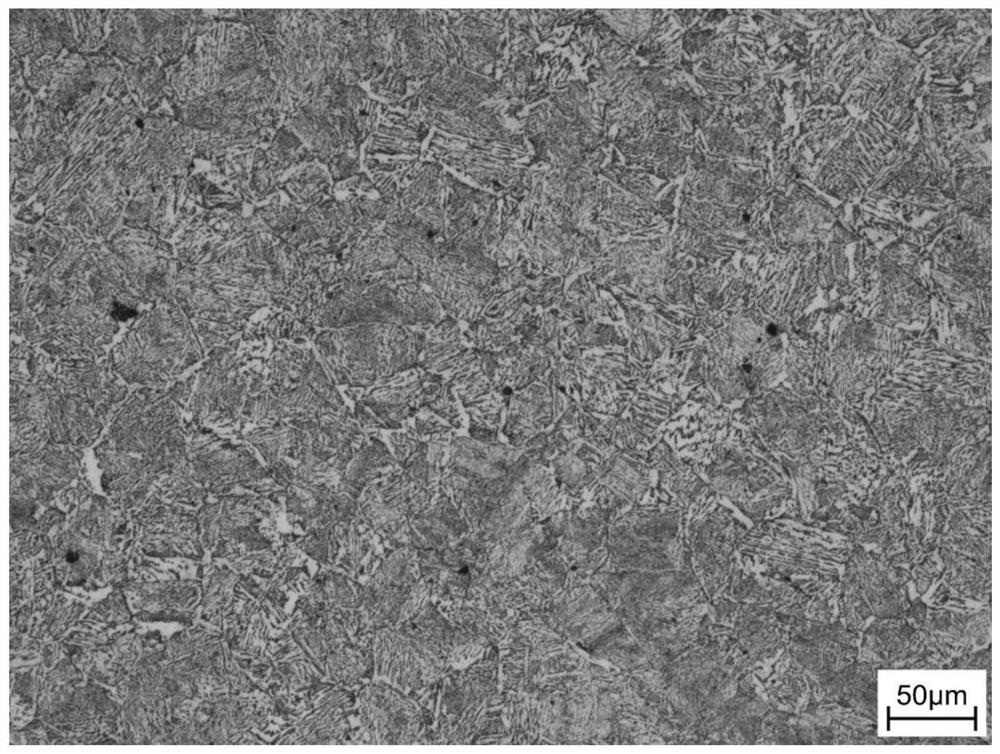

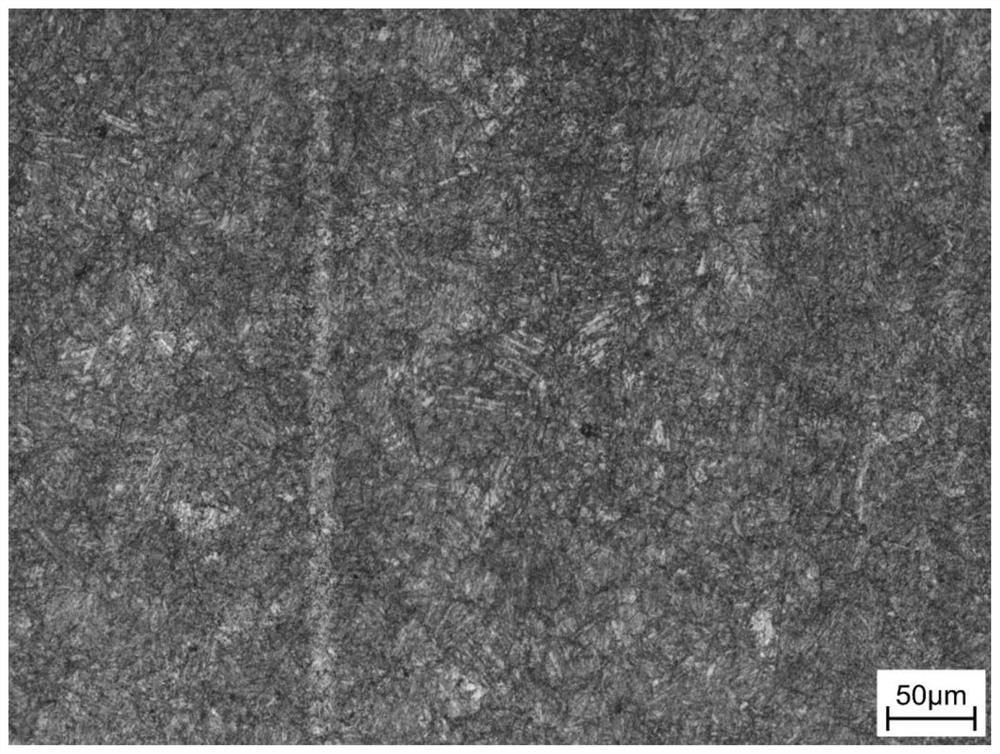

[0026] Step 3. At room temperature, completely immerse the polished surface of the special steel sample obtained in Step 2 in the dinitrophenol etchant prepared in Step 1. Rinse the corroded sample surface with ethanol after 5 to 10 seconds of corrosion, and place it in the oven after drying. The grain boundaries were observed under a metallographic microscope.

Embodiment 2

[0028] A metallographic corrosion method for rapidly displaying special steel grain boundaries, comprising the following steps:

[0029] Step 1. Prepare dinitrophenol etchant; at room temperature, thoroughly mix analytically pure grade phenol with a mass volume ratio of 5g:5mL and nitric acid with a mass concentration of 65%, and then obtain dinitrophenol etchant in 3-5 minutes.

[0030] Step 2. Roughly grind the surface of the special steel sample to remove the rust layer on the surface. The coarsely ground sample is finely ground on sandpaper; the finely ground sample surface is polished to obtain a bright and scratch-free surface. sample surface;

[0031] Step 3. At room temperature, completely immerse the polished surface of the special steel sample obtained in Step 2 in the dinitrophenol etchant prepared in Step 1. Rinse the corroded sample surface with ethanol after 5 to 10 seconds of corrosion, and place it in the oven after drying. The grain boundaries were observed u...

Embodiment 3

[0034] A metallographic corrosion method for rapidly displaying special steel grain boundaries, comprising the following steps:

[0035] Step 1: Prepare dinitrophenol etchant; at room temperature, thoroughly mix analytically pure grade phenol with a mass volume ratio of 5g:5mL and nitric acid with a mass concentration of 65% to obtain dinitrophenol etchant.

[0036] Step 2. Roughly grind the surface of the special steel sample to remove the rust layer on the surface. The coarsely ground sample is finely ground on sandpaper; the finely ground sample surface is polished to obtain a bright and scratch-free surface. sample surface;

[0037] Step 3. At room temperature, completely immerse the polished surface of the special steel sample obtained in Step 2 in the dinitrophenol etchant prepared in Step 1. Rinse the corroded sample surface with ethanol after 5 to 10 seconds of corrosion, and place it in the oven after drying. The grain boundaries were observed under a metallographic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com