PCB ink printing process method

A process method and ink printing technology, which is applied in the secondary processing of printed circuits, coating non-metallic protective layers, etc. Issues such as electrical performance of electrical function modules, to achieve the effect of thorough exposure, improved accuracy, and guaranteed electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

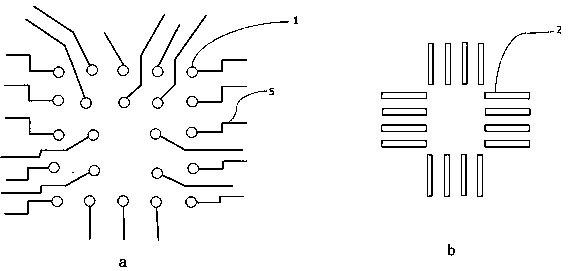

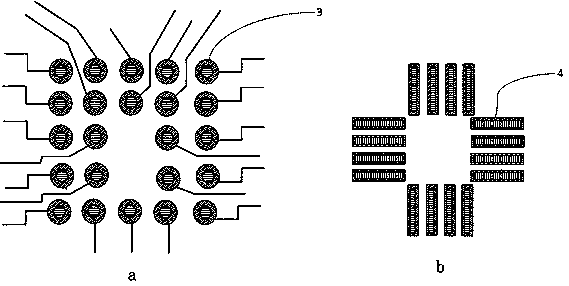

Image

Examples

Embodiment 1

[0026] A kind of PCB ink printing process method, used as the making of PCB board, comprises the following steps:

[0027] Step 1: Pre-treatment, through pre-treatment to enhance the adhesion of the ink on the PCB board, to ensure the adhesion of the ink, mainly for roughening treatment to enhance the adhesion of the ink on the PCB board, mechanical roughening or chemical roughening can be used Methods. For example, volcanic ash grinding or super-roughening treatment can be used. After roughening treatment, the degree of roughening can be checked by testing the wear marks. Generally, the wear marks are required to be between 10mm and 15mm. After mechanical roughening treatment, it needs to be cleaned. After cleaning, the effect of cleaning is tested by water film. Generally, the water film test requires more than 30S.

[0028] Step 2: Silk screen the first layer of ink, and use the process of screen printing to print a layer of ink on the entire area of the PCB board. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com