Liquid crystal alignment agent, liquid crystal alignment film, preparation method of liquid crystal alignment film and liquid crystal display element

A technology of liquid crystal alignment agent and liquid crystal alignment film, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of narrow exposure process window, adverse effects of non-exposed areas, and influence on display effect, so as to improve display effect and service life, excellent UV resistance, and the effect of increasing the working window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

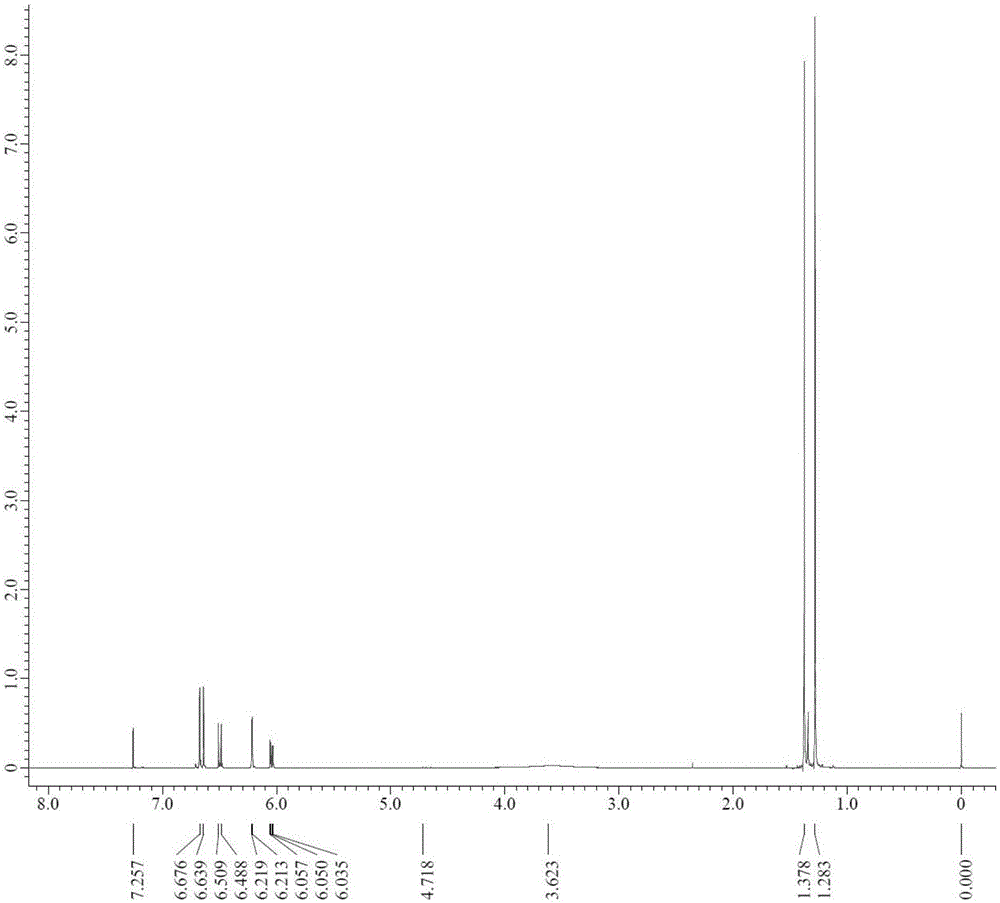

Image

Examples

Synthetic example 1

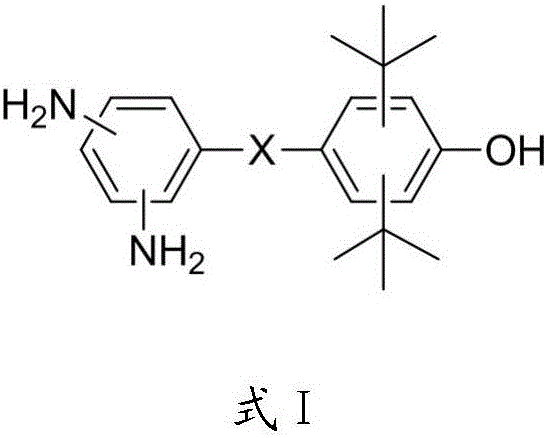

[0082] The compound represented by structural formula (I-1) can be synthesized according to the following synthetic route 1:

[0083]

[0084] (1) Synthesis of compound b-1-1a

[0085] Put 2,4-dinitrophenol (110.5g, 600mmol), anhydrous potassium carbonate (82.9g, 600mmol) and 400g N,N-dimethylformamide into a 1000mL three-necked round bottom flask, The resulting red suspension was stirred at room temperature for 10 minutes, and then the solution was heated to 60°C. Under stirring, it will contain 2,6-di-tert-butyl-4-bromophenol (171.1g, 600mmol) and 300g N , The solution of N-dimethylformamide dripped into the system, and the system exothermed. After all the solutions are added, keep stirring at 60-65°C for 2 hours. After the reaction was detected by gas chromatography (GC), the stirring was stopped and then suction filtered. The resulting black filtrate was acidified with dilute hydrochloric acid to acidity, and then 3L of water was added. The system precipitated solids. The re...

Synthetic example 2

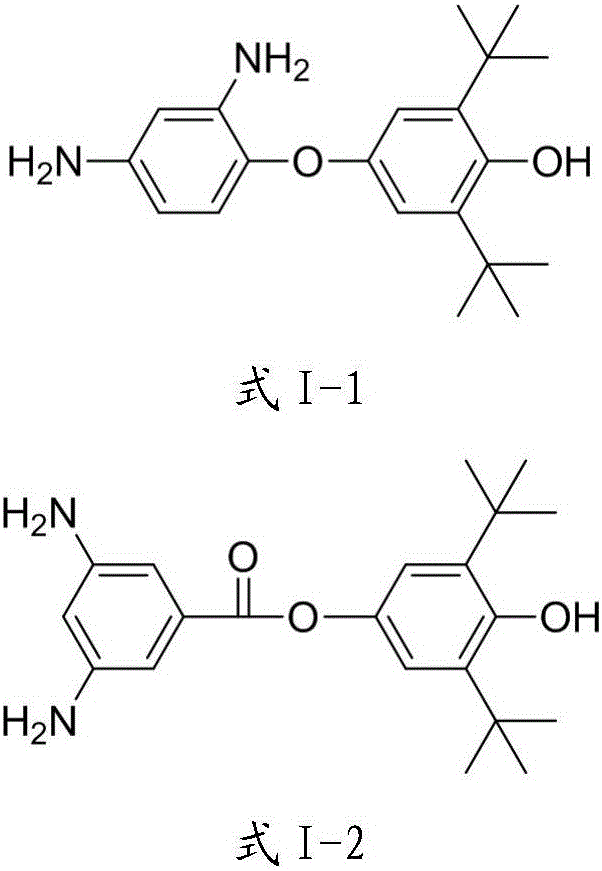

[0090] The compound represented by structural formula (I-2) can be synthesized according to the following synthetic route 2:

[0091]

[0092] (1) Synthesis of compound b-1-2a

[0093] Put 2,6-di-tert-butyl hydroquinone (44.4 g, 200 mmol), triethylamine (20.2 g, 200 mmol) and 400 g tetrahydrofuran into a 1000 mL three-necked round bottom flask, and the resulting suspension is in After stirring for 10 minutes at room temperature, a colorless solution was obtained. Then the temperature of the solution was lowered to 0°C. Under stirring, the solution containing 3,5-dinitrobenzoyl chloride (46.1g, 200mmol) and 100g tetrahydrofuran When dropped into the system, the system emits heat, and the dropping rate is controlled to keep the internal temperature below 20°C. After all the solutions are added, keep stirring at 15-20°C for 2 hours. After the reaction is detected by gas chromatography (GC), the stirring is stopped and then suction filtered. Under stirring, the filtrate is poured int...

Synthetic example 3

[0098] The compound represented by structural formula (I-3) can be synthesized according to the following synthetic route 3:

[0099]

[0100] (1) Synthesis of compound b-1-3a

[0101] In a nitrogen atmosphere, put 2,5-di-tert-butyl hydroquinone (133.4g, 600mmol), anhydrous potassium carbonate (82.9g, 600mmol) and 400g N in a 1000mL three-necked round bottom flask. , N-dimethylformamide, the resulting red suspension was stirred at room temperature for 10 minutes, then the solution was heated to 60 ℃, stirring, will contain 2,4-dinitrochlorobenzene (121.5g, 600 milli Mol) and 300g of N,N-dimethylformamide solution were dropped into the system, and the system exothermed. After all the solutions are added, keep stirring at 60-65°C for 2 hours. After the reaction is detected by gas chromatography (GC), the stirring is stopped, and then the inorganic salt and by-products are removed by suction filtration. The obtained black filtrate was acidified with dilute hydrochloric acid to acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com