Production process of ultrasonic atomization piece

A production process and a technology for atomizing sheets, applied in the field of atomizing sheets, can solve the problems of the decrease in the vibration amplitude of the film, the copper foil is easy to form wrinkles, and the stability is poor, and achieves improved work efficiency, good product consistency, and high controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] The production process of ultrasonic atomized sheet includes the following steps:

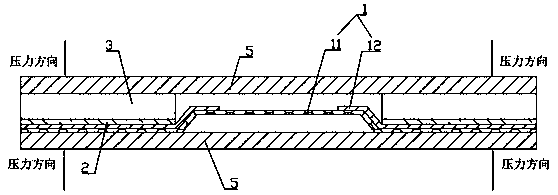

[0035] S1: cutting the pressure thermosetting conductive adhesive film 2 into a ring with the same size as the ring piezoelectric ceramic 3 for use;

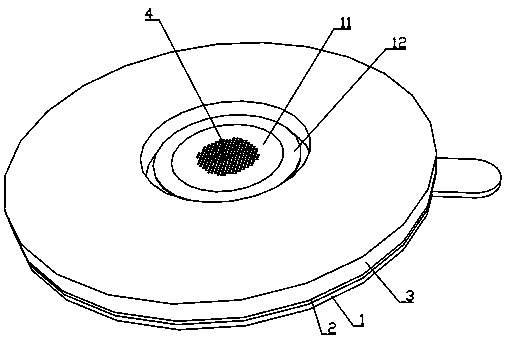

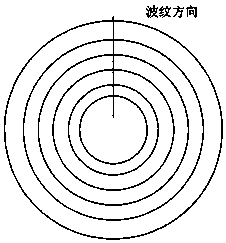

[0036] S2: Place the pressure thermosetting conductive adhesive film on the FPC flexible circuit board 1, wherein the FPC flexible circuit board 1 is composed of a circular PI film 11 and a ring-shaped copper foil 12, and then place the ring-shaped piezoelectric ceramic 3 on the pressure thermosetting conductive film. On film 2;

[0037] S3: Put a red silicone gasket 5 on the upper and lower sides of the product obtained in S2, then put it into a press, and the press is heated to 80-150°C at the same ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com